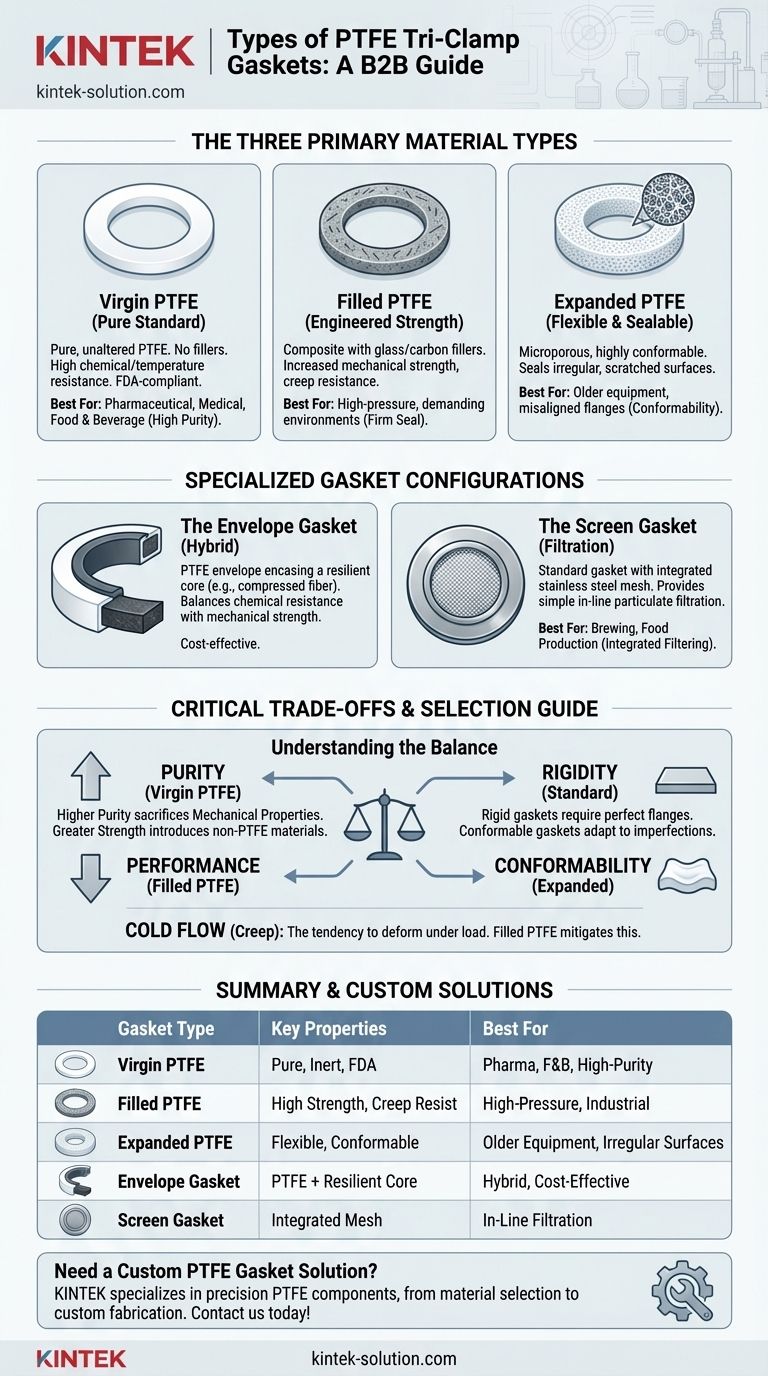

In short, PTFE tri-clamp gaskets are categorized into three primary material types. These are Virgin PTFE, which is pure and ideal for sanitary applications; Filled PTFE, which is enhanced with materials like glass or carbon for superior strength and creep resistance; and Expanded PTFE, which is highly flexible and excels at sealing irregular or damaged surfaces. Specialized functional designs, like Envelope and Screen gaskets, also exist for specific applications.

The optimal PTFE gasket is not a one-size-fits-all solution. The choice hinges on a critical trade-off between chemical purity (Virgin), mechanical strength (Filled), and surface conformability (Expanded), which must be matched to your specific operational pressures, temperatures, and equipment condition.

The Three Core PTFE Materials

Understanding the fundamental differences in PTFE material composition is the first step in selecting the correct gasket for your system. Each type is engineered to solve a different set of problems.

Virgin PTFE: The Pure Standard

Virgin PTFE is pure, unaltered polytetrafluoroethylene. It contains no fillers or reinforcing materials.

This makes it the go-to choice for applications demanding the highest purity, such as in pharmaceutical, medical, and food and beverage manufacturing. It is FDA-compliant and offers exceptional chemical and temperature resistance (from -100°F to 500°F / -73°C to 260°C).

Filled PTFE: Engineered for Strength

Filled PTFE is a composite material created by adding substances like glass, carbon, or graphite to Virgin PTFE.

This enhancement dramatically improves the gasket's mechanical properties. Fillers increase wear resistance, reduce deformation under load (creep), and boost overall strength, making these gaskets suitable for higher-pressure environments where a firm, stable seal is critical.

Expanded PTFE: Flexibility and Sealability

Expanded PTFE is made by molecularly rearranging Virgin PTFE, creating a microporous, soft, and highly flexible material.

Its key advantage is its ability to compress and conform to irregular, scratched, or slightly misaligned flange surfaces. While retaining the excellent chemical resistance of Virgin PTFE, its flexibility allows it to create a tight seal where more rigid gaskets would fail.

Specialized Gasket Configurations

Beyond the core material, some PTFE gaskets are designed with a specific structure or function in mind.

The Envelope Gasket: A Hybrid Approach

An envelope gasket combines the best of both worlds. It features a PTFE "envelope" or outer layer that encases a more resilient core material, like a compressed fiber.

This design places the chemically inert PTFE on all wetted surfaces while relying on the core insert to provide mechanical strength and compressibility. It offers an excellent balance of performance and cost-effectiveness.

The Screen Gasket: Integrated Filtration

A screen gasket is simply a standard tri-clamp gasket with a stainless steel mesh screen molded into the center.

Its purpose is to provide simple, in-line particulate filtration. These are commonly used in brewing, food production, and other processes to remove unwanted solids from the fluid stream without requiring separate filtration equipment.

Understanding the Critical Trade-offs

Choosing the right PTFE gasket requires acknowledging that no single type is superior in all conditions. Each comes with inherent compromises.

Purity vs. Performance

The primary trade-off is between Virgin PTFE and Filled PTFE. While Virgin PTFE offers the highest level of purity, its mechanical properties are limited. Filled PTFE provides superior strength and creep resistance but introduces a non-PTFE material into the system, which may not be acceptable for certain ultra-pure applications.

Rigidity vs. Conformability

Standard Virgin and Filled PTFE gaskets are relatively rigid. They require clean, flat, and perfectly aligned flange surfaces to create a reliable seal. Expanded PTFE sacrifices some rigidity for excellent conformability, making it the ideal choice for older equipment or surfaces with minor imperfections.

The Weakness of PTFE: Cold Flow

A key limitation of standard PTFE is "cold flow," or creep. This is the tendency of the material to slowly deform and extrude out from between the flanges under sustained compressive load. This can eventually lead to a loss of seal pressure and leaks. Filled PTFE was specifically developed to mitigate this exact problem.

Selecting the Right Gasket for Your Application

Your final decision should be guided by the specific demands of your process environment.

- If your primary focus is maximum chemical purity and FDA compliance: Choose a Virgin PTFE gasket for its unaltered, inert surface.

- If your primary focus is handling high pressure or preventing gasket creep: A Filled PTFE gasket provides the necessary mechanical stability.

- If you are sealing older, scratched, or slightly misaligned fittings: An Expanded PTFE gasket delivers the flexibility needed to ensure a tight seal.

- If you need PTFE's surface resistance but greater mechanical resilience: An Envelope Gasket offers a robust, cost-effective hybrid solution.

Ultimately, matching the unique properties of the gasket material to the operational demands of your system is the key to achieving a safe and reliable seal.

Summary Table:

| Gasket Type | Key Properties | Best For |

|---|---|---|

| Virgin PTFE | Pure, chemically inert, FDA compliant | Pharmaceutical, food & beverage, high-purity applications |

| Filled PTFE | High strength, creep resistance, durable | High-pressure systems, demanding industrial environments |

| Expanded PTFE | Flexible, conformable, seals irregular surfaces | Older equipment, scratched/damaged flanges, misaligned fittings |

| Envelope Gasket | PTFE envelope with resilient core | Cost-effective hybrid for chemical resistance & mechanical strength |

| Screen Gasket | Integrated stainless steel mesh | In-line filtration for brewing, food production, and processing |

Need a Custom PTFE Gasket Solution?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard tri-clamp gasket or a custom-designed solution, we deliver:

- Expert Material Selection: We help you choose between Virgin, Filled, or Expanded PTFE based on your specific pressure, temperature, and purity requirements.

- Custom Fabrication: From prototypes to high-volume orders, we tailor gaskets to fit your exact specifications.

- Reliable Performance: Our PTFE components are engineered for superior chemical resistance, durability, and leak-free operation.

Let us help you achieve a perfect seal. Contact our team today to discuss your application needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications