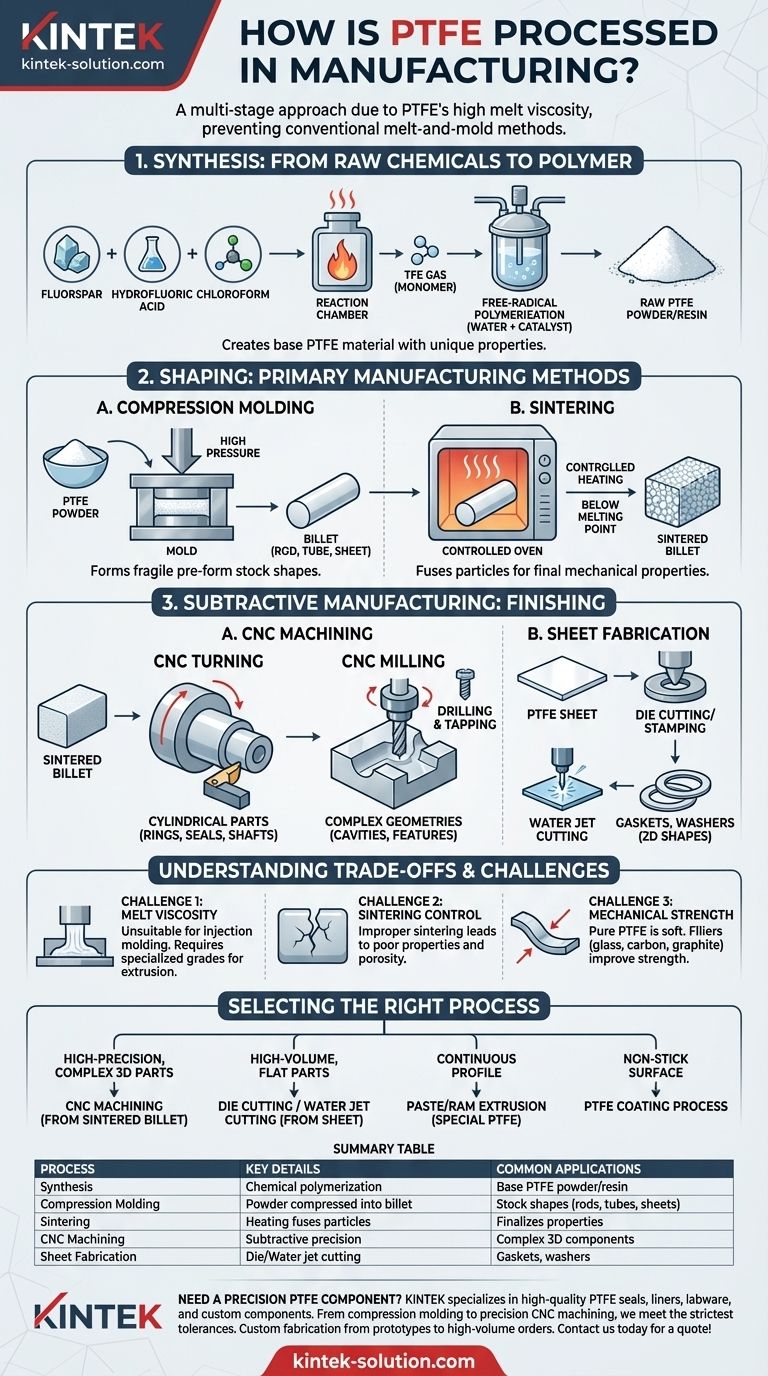

To manufacture products from Polytetrafluoroethylene (PTFE), processors use a multi-stage approach that begins with chemical synthesis and is followed by shaping techniques like compression molding, sintering, and CNC machining. Unlike common thermoplastics, PTFE's extremely high melt viscosity prevents it from being processed through conventional melt-and-mold methods, requiring these specialized steps.

The core challenge in processing PTFE is its inability to be truly melted and flowed like other plastics. Therefore, manufacturing relies on compressing and heating (sintering) PTFE powder into solid forms, which are then precisely machined into the final component.

From Raw Chemicals to Polymer: The Synthesis of PTFE

Before any part can be shaped, the base PTFE material must be created through a complex chemical process. This foundational stage dictates the material's unique properties.

The Starting Ingredients

The synthesis process begins with common industrial chemicals. The primary ingredients are fluorspar, hydrofluoric acid, and chloroform.

The Polymerization Process

These chemicals are heated in a reaction chamber to synthesize tetrafluoroethylene (TFE) gas. This gas is the monomer, or the single molecular building block, of PTFE.

The TFE gas then undergoes a process called free-radical polymerization. It is mixed with water and a catalyst, causing the individual TFE molecules to link together into long, stable chains, forming the solid PTFE polymer.

The Result: Raw PTFE Forms

This process yields raw PTFE, typically in the form of fine powders or granular resins. This is the base material that will be used in all subsequent shaping and fabrication steps.

Shaping PTFE: The Primary Manufacturing Methods

Once raw PTFE powder is produced, it must be consolidated and formed into a desired geometry. This is typically a two-part process involving consolidation and then subtractive finishing.

Compression Molding and Sintering

The most common first step is compression molding. PTFE powder is poured into a mold and compressed under high pressure to form a pre-form, often a basic stock shape like a rod, tube, or sheet (also called a "billet").

This compressed billet is still fragile. To achieve its final properties, it must be heated in a controlled oven in a process called sintering. The temperature is raised just below the material's melting point, causing the individual PTFE particles to fuse together into a solid, dense mass.

Subtractive Manufacturing: CNC Machining

After sintering, the stock shapes are most often finished using Computer Numerical Control (CNC) machining. This subtractive process cuts away material to create precise, final parts with tight tolerances.

CNC Turning

For cylindrical components like rings, seals, gaskets, and shafts, CNC turning is used. The PTFE stock rod is rotated at high speed while a cutting tool removes material to create the desired profile.

CNC Milling

For more intricate parts with complex geometries, cavities, or non-symmetrical features, CNC milling is the preferred method. A rotating multi-point cutting tool moves across the stationary PTFE block to carve out the final shape.

Drilling and Tapping

Standard machining operations like drilling to create holes and tapping to create internal threads are also frequently performed on PTFE components.

Sheet Fabrication Methods

For producing flat parts like gaskets or seals from PTFE sheets, several methods are used. These include die cutting, stamping, punching, and water jet cutting, which are ideal for high-volume production of 2D shapes.

Understanding the Trade-offs and Challenges

PTFE's unique properties introduce manufacturing constraints that are not present with other polymers. Understanding these is critical for successful component design.

The Difficulty of Conventional Molding

Standard PTFE has an exceptionally high melt viscosity, meaning it doesn't flow even when heated past its melting point. This makes it unsuitable for traditional injection molding, a process used for most common plastics. Specialized, modified grades of PTFE are required for processes like paste or ram extrusion to create tubes and wires.

The Critical Role of Sintering

The sintering step is non-negotiable and must be carefully controlled. Improper sintering can lead to a component with poor mechanical properties, high porosity, and diminished performance, even if it appears dimensionally correct.

The Impact of Fillers

While pure PTFE is incredibly slick and chemically resistant, it is also soft and prone to deforming under load (creep). To improve mechanical strength, stiffness, and wear resistance, fillers like glass fiber, carbon, or graphite are often blended with the PTFE powder before the molding and sintering stages.

Selecting the Right Process for Your Application

Choosing the correct manufacturing path depends entirely on the part's geometry, required precision, and production volume.

- If your primary focus is high-precision, complex 3D parts (like valve seats or insulators): Your path is CNC machining from a compression-molded and sintered PTFE billet.

- If your primary focus is high-volume, flat parts (like gaskets or washers): Your best option is die cutting or water jet cutting from a pre-made PTFE sheet.

- If your primary focus is a continuous profile (like tubing or wire insulation): You will need to specify a process like paste or ram extrusion, which uses a modified form of PTFE.

- If your primary focus is a non-stick surface on a metal part (like cookware): You are looking for a PTFE coating process, where a liquid dispersion is sprayed on and cured.

Understanding these distinct manufacturing pathways is the key to successfully harnessing the remarkable capabilities of PTFE for your specific application.

Summary Table:

| Process Step | Key Details | Common Applications |

|---|---|---|

| Synthesis | Chemical polymerization of TFE gas. | Creates base PTFE powder/resin. |

| Compression Molding | Powder is compressed into a pre-form (billet). | Creates stock shapes (rods, tubes, sheets). |

| Sintering | Heating to fuse particles; critical for strength. | Finalizes the molded billet's properties. |

| CNC Machining | Subtractive process for high-precision parts. | Complex 3D components (seals, insulators). |

| Sheet Fabrication | Die cutting, water jet cutting for flat parts. | High-volume gaskets, washers. |

Need a precision PTFE component?

KINTEK specializes in manufacturing high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in compression molding, sintering, and precision CNC machining ensures your parts meet the strictest tolerances and performance requirements.

We offer custom fabrication from prototypes to high-volume orders. Let us help you solve your unique application challenges with PTFE.

Contact us today for a quote or to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications