In short, PTFE seats are preferred in electric actuated butterfly valves for their unique combination of superior chemical resistance, high-temperature stability, and extremely low friction. These properties ensure the valve operates reliably and efficiently over a long lifespan, which is critical for automated systems where precision and durability are paramount.

The choice of a valve seat material is not just about withstanding the process fluid; it's about optimizing the entire automated system. PTFE's low-friction nature directly reduces the mechanical load on the electric actuator, allowing for more efficient sizing and extending the service life of both the valve and the motor.

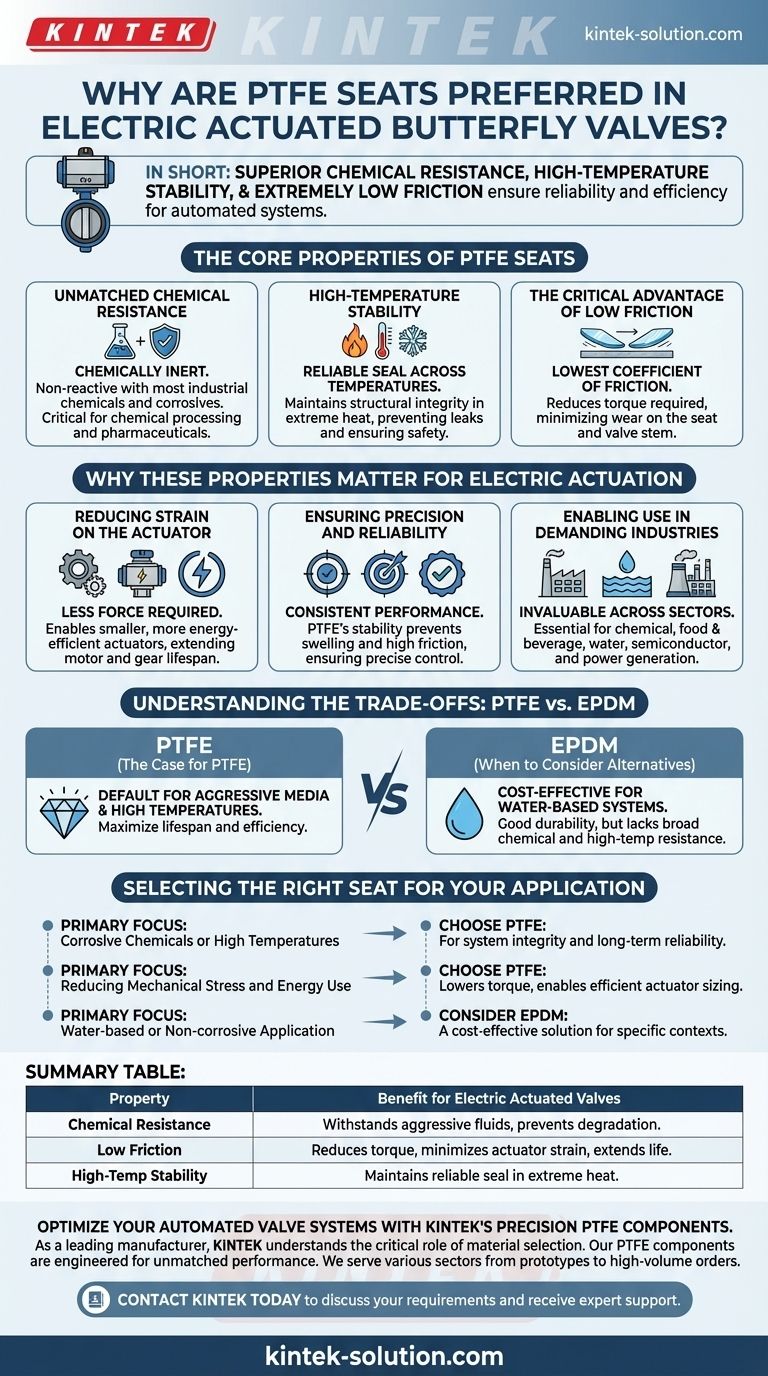

The Core Properties of PTFE Seats

To understand why PTFE (Polytetrafluoroethylene) is the material of choice, we must first examine its fundamental characteristics. These properties work in concert to deliver exceptional performance in demanding industrial environments.

Unmatched Chemical Resistance

PTFE is almost completely chemically inert, meaning it is non-reactive with the vast majority of industrial chemicals and corrosive substances.

This property is critical in applications like chemical processing, petrochemicals, and pharmaceuticals, where aggressive fluids would quickly degrade lesser materials, leading to valve failure and potential system contamination.

High-Temperature Stability

PTFE maintains its structural integrity and sealing capability across a wide temperature range.

This thermal stability ensures a reliable seal in systems that experience extreme temperatures, preventing leaks that could compromise safety, efficiency, and the integrity of the actuator itself.

The Critical Advantage of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This characteristic is a significant advantage in an actuated valve. It dramatically reduces the torque required to open and close the valve disc, minimizing wear and tear on the seat and the valve stem over thousands of cycles.

Why These Properties Matter for Electric Actuation

The benefits of PTFE are magnified when paired with an electric actuator. The actuator is the engine of the valve, and the seat material directly impacts its performance and longevity.

Reducing Strain on the Actuator

Because a PTFE seat requires less force to operate, a smaller, more energy-efficient, and less expensive electric actuator can often be used.

The lower torque requirement also reduces the mechanical stress on the actuator's motor and gearing, which is a primary factor in extending the operational lifespan of the entire assembly.

Ensuring Precision and Reliability

Electric actuators are selected for their ability to provide precise, repeatable control. A valve seat that swells, degrades, or creates high friction would introduce variables that undermine this precision.

PTFE's stability ensures that the actuator's performance remains consistent and reliable throughout its service life, which is essential for automated process control.

Enabling Use in Demanding Industries

The combination of these properties makes PTFE-seated electric actuated valves invaluable across numerous sectors.

They are widely used in chemical processing, food and beverage, water treatment, semiconductor manufacturing, and power generation—industries where failure is not an option and operational demands are severe.

Understanding the Trade-offs: PTFE vs. Other Materials

While PTFE is a superior choice for many applications, it is not the only option. Understanding the alternatives provides a clearer picture of its specific advantages.

The Case for PTFE

PTFE is the default choice for applications involving aggressive media, high temperatures, or when maximizing the lifespan and efficiency of the automation system is the top priority.

When to Consider Alternatives like EPDM

For certain applications, other materials may be suitable. EPDM (Ethylene Propylene Diene Monomer) seats, for example, offer excellent durability and water resistance.

EPDM is often a cost-effective and reliable choice for water-based systems, but it lacks the broad chemical and high-temperature resistance of PTFE.

Selecting the Right Seat for Your Application

Ultimately, the choice of seat material must align with the specific demands of the process and the goals of the automation system.

- If your primary focus is handling corrosive chemicals or high temperatures: PTFE is the definitive choice for ensuring system integrity and long-term reliability.

- If your primary focus is reducing mechanical stress and energy use: PTFE's low friction directly lowers torque requirements, allowing for more efficient actuator sizing and reducing wear.

- If your primary focus is a water-based or non-corrosive application: An alternative like EPDM may provide a more cost-effective solution without compromising performance in that specific context.

Matching the seat material to your operational demands is the foundational step in building a truly reliable and efficient automated valve system.

Summary Table:

| Property | Benefit for Electric Actuated Valves |

|---|---|

| Chemical Resistance | Withstands aggressive fluids, preventing seat degradation and system contamination. |

| Low Friction | Reduces operating torque, minimizing strain on the actuator and extending its life. |

| High-Temperature Stability | Maintains a reliable seal in extreme heat, ensuring consistent performance. |

Optimize your automated valve systems with KINTEK's precision PTFE components.

As a leading manufacturer of high-performance PTFE seals, liners, and labware, KINTEK understands the critical role material selection plays in the reliability and efficiency of electric actuated valves. Our PTFE components are engineered to provide the unmatched chemical resistance, low friction, and thermal stability detailed in this article, directly contributing to reduced actuator wear, lower energy consumption, and longer system lifespans.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders. Let us help you specify the right component for your demanding application.

Contact KINTEK today to discuss your specific requirements and receive expert support.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments