In its pure, unfilled form, Polytetrafluoroethylene (PTFE) sheet is prized for applications demanding exceptional chemical inertness and a low-friction surface. The most common applications are gaskets for aggressive chemical services, liners for tanks and vessels, and high-purity, non-stick surfaces for food, medical, and semiconductor manufacturing. Its value comes from what it doesn't do: react, corrode, or stick.

Unfilled PTFE is the benchmark for chemical and electrical resistance. However, this purity comes at the cost of mechanical performance. Understanding this fundamental trade-off is the key to using it correctly.

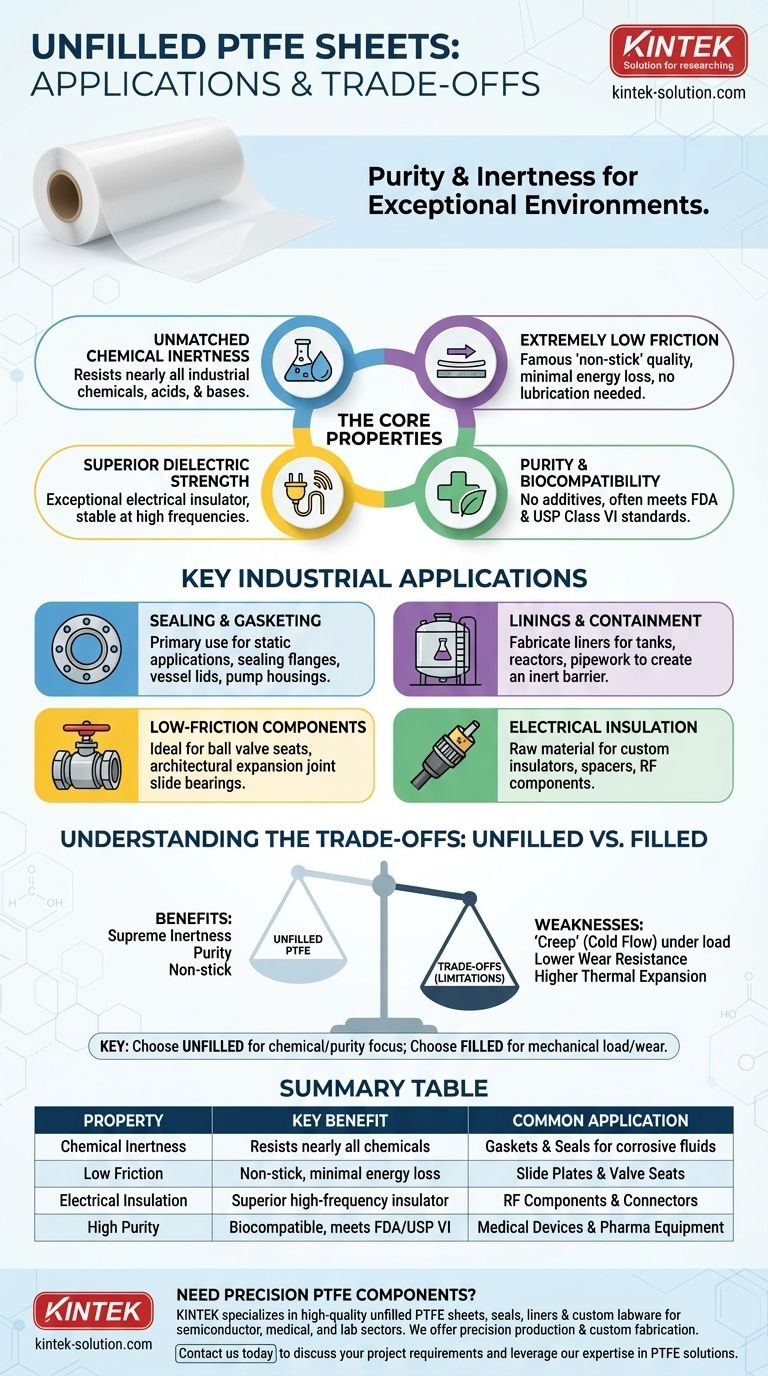

The Core Properties Driving Its Use

To understand where to apply unfilled PTFE sheet, you must first understand its defining characteristics. Unlike materials that are engineered for strength, unfilled PTFE is engineered for inertness.

Unmatched Chemical Inertness

Unfilled PTFE is famously non-reactive and resistant to nearly all industrial chemicals, acids, and bases. This makes it an essential material for handling corrosive and high-purity fluids.

This property is why it is the default choice for gaskets and seals in chemical processing plants. It can seal flanges containing substances that would destroy almost any other polymer.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid, giving it its famous "non-stick" quality.

This allows it to be used for low-load slide plates, anti-friction pads, and valve seats. Components can move against its surface with minimal energy loss and no need for external lubrication.

Superior Dielectric Strength

Unfilled PTFE is an exceptional electrical insulator, especially at high frequencies. It maintains its insulating properties across a wide range of temperatures and environmental conditions.

This makes it invaluable in electronics, where sheets are machined into insulators for high-frequency coaxial cables and other critical electronic components.

Purity and Biocompatibility

Because it contains no additives, unfilled PTFE is inherently pure and can often meet strict regulatory standards like FDA and USP Class VI.

Its biocompatibility and inertness make it suitable for medical devices, pharmaceutical processing equipment, and components used in semiconductor fabrication where contamination is a major concern.

Key Industrial Applications Breakdown

These core properties translate directly into specific, high-value industrial uses.

Sealing and Gasketing

This is the most common application. A gasket cut from an unfilled PTFE sheet will conform to flange imperfections to create a tight seal.

Its primary use is in static applications, such as sealing pipe flanges, vessel lids, and pump housings in the chemical, pharmaceutical, and food and beverage industries.

Linings and Containment

Large sheets of unfilled PTFE are often used to fabricate liners for chemical storage tanks, reactors, and pipework.

This creates an inert barrier, protecting the structural material (often steel or fiberglass) from the corrosive contents within.

Low-Friction Components

In applications where friction is the enemy but mechanical loads are low, unfilled PTFE excels.

Common examples include ball valve seats, slide bearings for architectural expansion joints, and simple wear strips that guide components smoothly.

Electrical Insulation

Designers use unfilled PTFE sheet as a raw material to machine custom insulators, spacers, and connectors.

Its stability at high frequencies makes it critical for microwave and radio-frequency (RF) applications where signal loss must be minimized.

Understanding the Trade-offs: Unfilled vs. Filled PTFE

Choosing unfilled PTFE without understanding its limitations is a common and costly mistake. Its purity is also its primary weakness from a mechanical standpoint.

The Challenge of "Creep" (Cold Flow)

Unfilled PTFE is a relatively soft material that is subject to creep, or cold flow. When a compressive load is applied over time, the material will slowly deform and "flow" away from the pressure.

This makes it unsuitable for high-pressure gaskets or structural components that must maintain precise dimensions under a constant load.

Lower Wear Resistance

The same low-friction quality that makes PTFE non-stick also means it abrades easily. It has poor wear resistance in dynamic applications with significant friction or abrasion.

For components like high-load bearings, piston rings, or dynamic seals, filled PTFE grades (which contain glass, carbon, or bronze) offer vastly superior wear life and mechanical strength.

Higher Thermal Expansion

Unfilled PTFE expands and contracts with temperature changes more than most engineering plastics. This high coefficient of thermal expansion must be accounted for in designs with tight tolerances that operate across a wide temperature range.

Making the Right Choice for Your Application

The decision between unfilled and filled PTFE is not about which is "better," but which is right for the job.

- If your primary focus is chemical resistance or purity: Unfilled PTFE is the correct choice for static seals, linings, and non-stick surfaces in corrosive or high-purity environments.

- If your primary focus is mechanical performance: A filled PTFE grade is required for any application involving significant load, wear, or the need for dimensional stability, such as bearings or dynamic seals.

Ultimately, select unfilled PTFE for its supreme inertness when mechanical demands are minimal.

Summary Table:

| Property | Key Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals | Gaskets & Seals for corrosive fluids |

| Low Friction | Non-stick, minimal energy loss | Slide Plates & Valve Seats |

| Electrical Insulation | Superior high-frequency insulator | RF Components & Connectors |

| High Purity | Biocompatible, meets FDA/USP VI | Medical Devices & Pharma Equipment |

Need precision-engineered PTFE components for your critical application?

KINTEK specializes in manufacturing high-quality, unfilled PTFE sheets, seals, liners, and custom labware for industries where chemical resistance and purity are paramount, including semiconductor, medical, and laboratory sectors. We combine precision production with custom fabrication, from prototypes to high-volume orders, ensuring your components meet exact specifications.

Contact us today to discuss your project requirements and leverage our expertise in PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are some tips for successfully machining PTFE? Master Precision Cuts for Soft, Heat-Sensitive Material

- What are the standard bearing assembly configurations for PTFE slide bearings? Choose the Right PTFE Bearing for Your Project

- How do PTFE gaskets stabilize pump and gear housing? Prevent Degradation for Long-Term Stability

- Are Teflon backup rings suitable for food processing applications? Ensure Safety and Reliability

- What are the common applications of virgin Teflon balls? Ideal for Chemical Resistance & Purity

- What are some common structural types of PTFE gaskets? Choose the Right Seal for Your Application

- Why is lubrication important in PTFE machining? Master Heat Control for Precision Parts

- What are the two main types of lip seals? PTFE Metal-Cased vs. All-Polymer Seals Explained