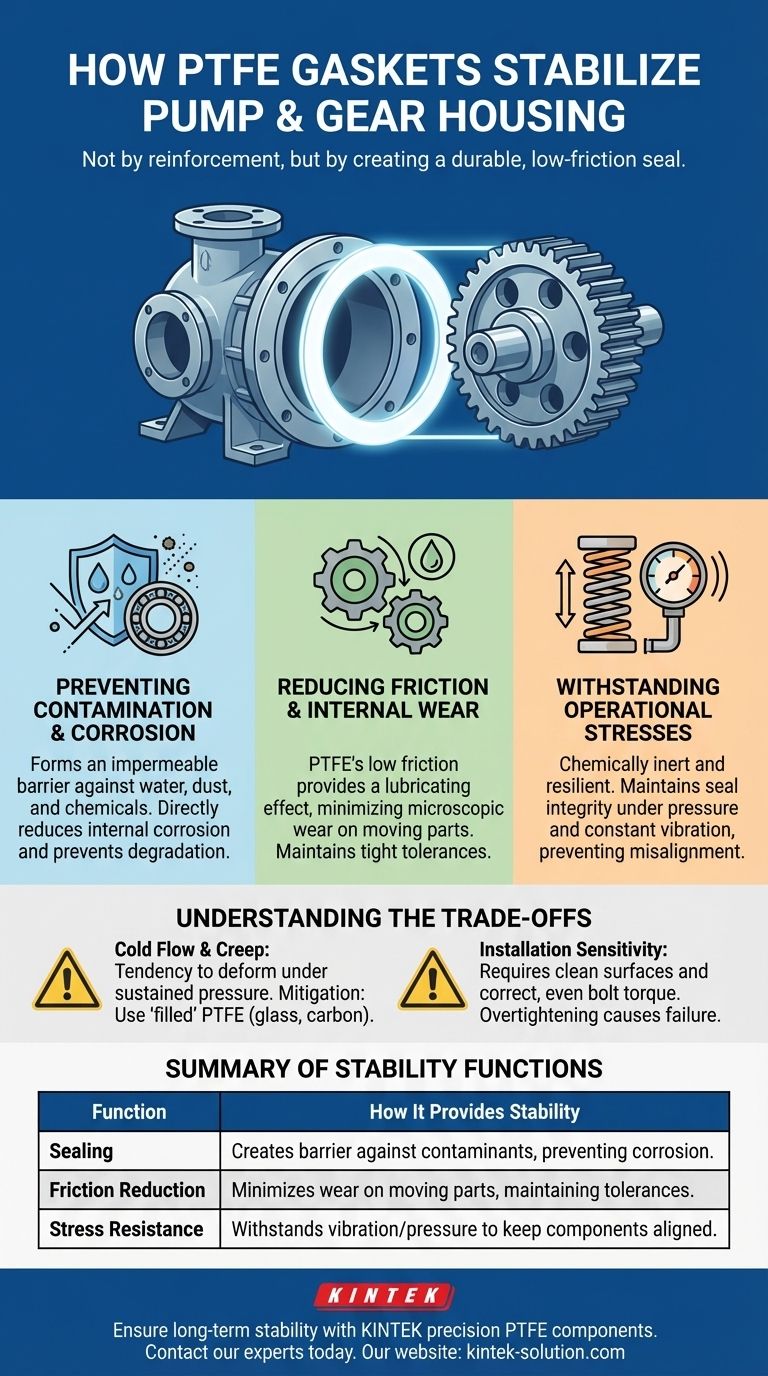

To be precise, PTFE gaskets stabilize pump and gear housings not by adding structural rigidity, but by creating a highly durable and low-friction seal. This seal protects internal components from corrosive contaminants like water, reduces wear between moving parts, and withstands operational vibrations, all of which preserves the long-term mechanical integrity of the assembly.

The core function is not reinforcement, but prevention. PTFE gaskets stabilize equipment by creating an optimized internal environment that minimizes the gradual degradation, corrosion, and wear that would otherwise lead to looseness, vibration, and eventual failure.

The Core Functions of PTFE in Mechanical Housings

To understand how a simple gasket provides stability, we must look at its specific properties and how they counteract the primary forces that destabilize mechanical systems over time.

Preventing Contamination and Corrosion

The most direct way PTFE gaskets provide stability is by forming an impermeable barrier. They effectively prevent the ingress of water, dust, and other contaminants into critical areas like bearings.

This sealing action directly reduces internal corrosion. By keeping the mechanics clean and dry, the gasket ensures that bearings and gears do not degrade, which is a primary cause of increased vibration and loss of alignment.

Reducing Friction and Internal Wear

PTFE is renowned for its extremely low coefficient of friction, making it one ofthe slickest materials available. When used in gaskets, it provides a lubricating effect for components like bearing assemblies or fastening bolts.

This reduction in friction minimizes microscopic wear and tear on moving parts. Over thousands of operational hours, this prevents the development of slack or "play" in the system, maintaining tight tolerances and stable performance.

Withstanding Operational Stresses

Pump and gear housings are subject to constant operational stress and vibration. A gasket material must be able to withstand these forces without degrading.

PTFE is chemically inert and resilient, allowing it to maintain its seal integrity under pressure. This ensures that the components remain securely fastened and aligned, preventing instability caused by a failing seal.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Its unique properties introduce specific considerations that are critical for successful implementation.

Cold Flow and Creep

The primary limitation of pure PTFE is its tendency to "creep" or cold flow. Under sustained pressure and temperature, the material can slowly deform, which may lead to a loss of bolt torque and sealing pressure over time.

This is often mitigated by using "filled" PTFE gaskets, which incorporate materials like glass, carbon, or silica to enhance rigidity and resistance to creep.

Installation Sensitivity

The effectiveness of a PTFE gasket is highly dependent on proper installation. The sealing surfaces must be impeccably clean and smooth.

Furthermore, applying the correct and even bolt torque is critical. Overtightening can crush the gasket and cause premature failure, while under-tightening will result in a poor seal, defeating its purpose entirely.

Making the Right Choice for Your Application

Selecting the right gasket depends on the specific problem you are trying to solve within the pump or gearbox.

- If your primary focus is preventing environmental contamination: A standard PTFE gasket provides an exceptional chemical and moisture barrier, directly reducing the risk of internal corrosion.

- If your primary focus is reducing internal friction: PTFE's inherent lubricity is ideal for applications where minimizing wear on bearings and fasteners is the main goal to improve efficiency and service life.

- If your primary focus is overall system reliability: The combined benefits of sealing, lubrication, and durability make PTFE a strategic choice for maintaining the long-term operational stability of the entire housing.

Ultimately, using a PTFE gasket is a proactive measure to preserve the precise engineering of your equipment from the inside out.

Summary Table:

| Function | How It Provides Stability |

|---|---|

| Sealing | Creates an impermeable barrier against water, dust, and chemicals to prevent internal corrosion. |

| Friction Reduction | Its low coefficient of friction minimizes wear on bearings and moving parts, maintaining tight tolerances. |

| Stress Resistance | Withstands operational vibrations and pressure to ensure components remain securely aligned. |

Ensure the long-term stability and reliability of your equipment with precision PTFE components from KINTEK.

Whether you are in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, and labware are engineered to protect your critical assemblies from contamination, reduce wear, and extend service life. From prototypes to high-volume orders, we deliver the precision you need.

Contact our experts today to discuss your specific application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance