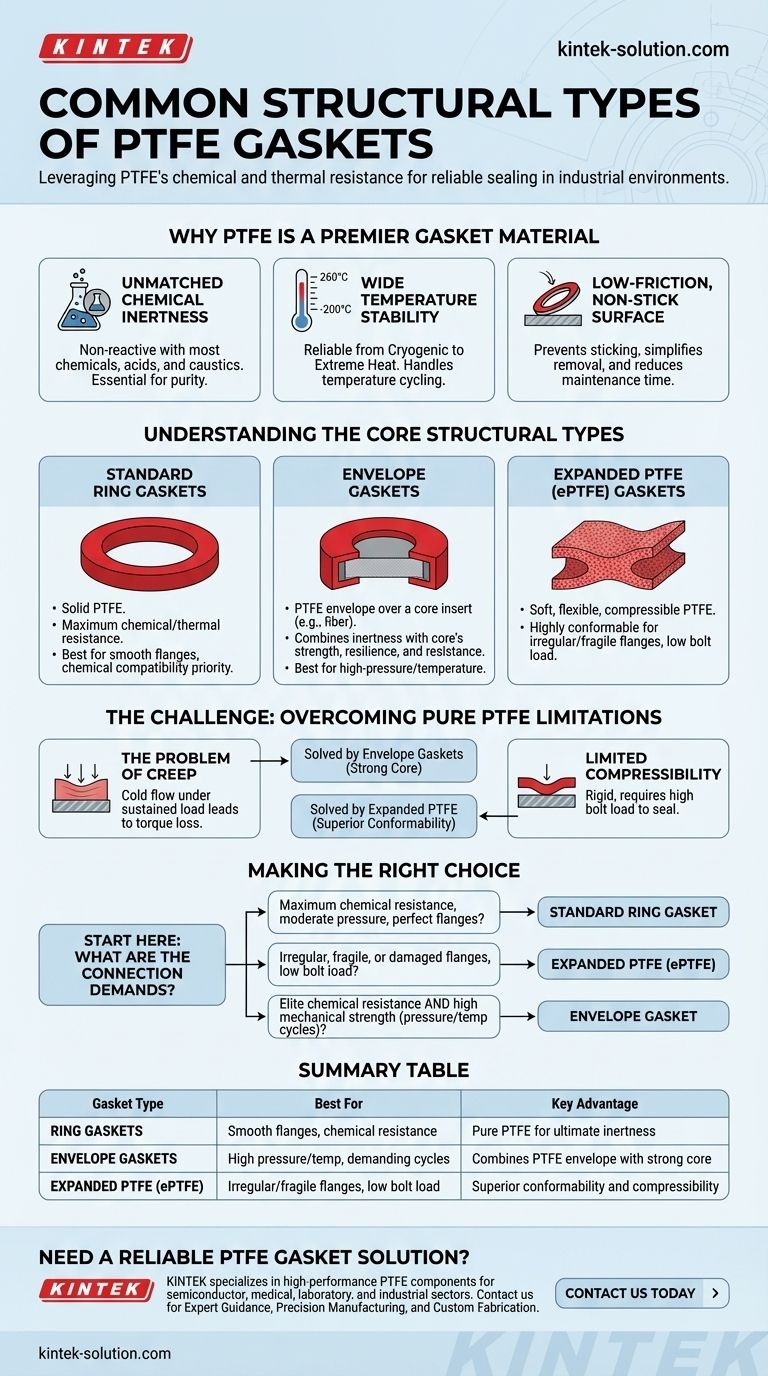

At its core, the most common structural types of PTFE gaskets are Ring Gaskets, Envelope Gaskets, and Expanded PTFE (ePTFE) Gaskets. Each design leverages the exceptional chemical and thermal resistance of PTFE while addressing specific mechanical sealing challenges, such as pressure, flange condition, and bolt load.

The various structures of PTFE gaskets are not arbitrary; they are specific engineering solutions designed to combine PTFE's unparalleled chemical inertness with the mechanical performance needed for a reliable, long-lasting seal in different industrial environments.

Why PTFE is a Premier Gasket Material

Polytetrafluoroethylene (PTFE) possesses a unique combination of properties that makes it a top-tier choice for sealing applications, especially in aggressive environments. Understanding these fundamentals is key to choosing the right gasket structure.

Unmatched Chemical Inertness

PTFE is non-reactive with the vast majority of chemicals, acids, and caustics. This makes it an essential material for chemical processing, pharmaceutical, and food production where contamination or material degradation is unacceptable.

Wide Temperature Stability

PTFE gaskets perform reliably across an exceptionally broad temperature range, typically from cryogenic lows of -200°C (-328°F) up to 260°C (500°F). This allows for their use in systems with extreme temperature cycling.

Low-Friction, Non-Stick Surface

The material's inherently low friction and non-adhesive surface prevent the gasket from sticking to flange surfaces. This simplifies removal and cleaning, reducing maintenance time and preventing damage to equipment.

Understanding the Core Structural Types

While pure PTFE is remarkable, it has mechanical limitations. The different structural types are designed to either enhance its strengths or compensate for its weaknesses.

Standard Ring Gaskets

This is the most basic form: a solid ring of pure, virgin PTFE, typically cut from a sheet. It offers the maximum chemical and thermal resistance inherent to the material.

These gaskets are ideal for applications where chemical compatibility is the absolute priority and sealing surfaces are smooth and flat.

Expanded PTFE (ePTFE) Gaskets

Expanded PTFE is created by modifying the polymer structure, resulting in a material that is soft, flexible, and highly compressible.

This conformability makes ePTFE excellent for sealing irregular, damaged, or fragile flanges (like glass-lined steel) that cannot withstand the high bolt torque required to compress a solid PTFE ring.

Envelope Gaskets

An envelope gasket combines the best of two materials. It consists of a core insert material (such as compressed non-asbestos fiber) enclosed within a thin "envelope" of PTFE.

This design provides the robust mechanical strength, resilience, and creep resistance of the core insert while ensuring only the chemically inert PTFE envelope touches the sealed media. This makes it ideal for high-pressure and high-temperature applications.

Understanding the Trade-offs: The Challenge of Pure PTFE

No material is perfect. The sophisticated structures of ePTFE and envelope gaskets were developed specifically to overcome the primary mechanical weakness of pure, solid PTFE.

The Problem of Creep

The biggest limitation of solid PTFE is creep, or "cold flow." Under the sustained compressive load of a bolted flange, the material can slowly deform and flow out of the seal area. This leads to a loss of bolt torque and, eventually, a failed seal.

Limited Compressibility

Solid PTFE is a relatively rigid plastic. It requires significant bolt load to compress and "flow" into the minor imperfections of a flange surface to create a tight seal, which isn't always possible or desirable.

How Structural Variations Solve This

Expanded PTFE directly solves the compressibility problem, creating a tight seal with very little bolt force. Envelope gaskets solve the creep problem by relying on a mechanically stable core to maintain sealing pressure over time.

Making the Right Choice for Your Application

Selecting the correct gasket structure is crucial for ensuring the integrity and safety of your system. Your choice should be guided by the specific demands of the connection.

- If your primary focus is maximum chemical resistance in a moderate-pressure system with perfect flanges: A standard pure PTFE ring gasket is the most direct and cost-effective choice.

- If you are dealing with irregular, fragile, or damaged flanges requiring a seal with low bolt load: Expanded PTFE (ePTFE) offers the superior conformability needed for a reliable seal.

- If you need both elite chemical resistance and high mechanical strength for demanding pressure or temperature cycles: An envelope gasket with a suitable core insert provides the best combination of performance.

Ultimately, selecting the right PTFE gasket structure is about matching the material's unique chemical properties with the specific mechanical demands of your connection.

Summary Table:

| Gasket Type | Best For | Key Advantage |

|---|---|---|

| Ring Gaskets | Smooth flanges, maximum chemical resistance | Pure PTFE for ultimate inertness |

| Envelope Gaskets | High pressure/temperature, demanding cycles | Combines PTFE envelope with strong core |

| Expanded PTFE (ePTFE) | Irregular/fragile flanges, low bolt load | Superior conformability and compressibility |

Need a Reliable PTFE Gasket Solution?

Selecting the correct gasket structure is critical for system integrity and safety. KINTEK specializes in manufacturing high-performance PTFE components, including custom gaskets, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Guidance: Help you choose the optimal gasket design (Ring, Envelope, or ePTFE) for your specific pressure, temperature, and chemical requirements.

- Precision Manufacturing: Ensure a perfect, reliable seal every time.

- Custom Fabrication: From prototype to high-volume production, tailored to your exact needs.

Contact us today to discuss your project and get a quote. Let our expertise ensure your sealing solution is a perfect fit.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems