In short, lubrication is critical in PTFE machining because it is the primary method for controlling heat. Unmanaged heat causes PTFE to expand significantly, ruining dimensional accuracy, while also reducing tool life and degrading the surface finish of the final part.

The central challenge in machining PTFE isn't its hardness, but its extreme sensitivity to heat. Effective lubrication or cooling is less about making the material easier to cut and more about preventing thermal expansion to ensure the finished part meets its required tolerances.

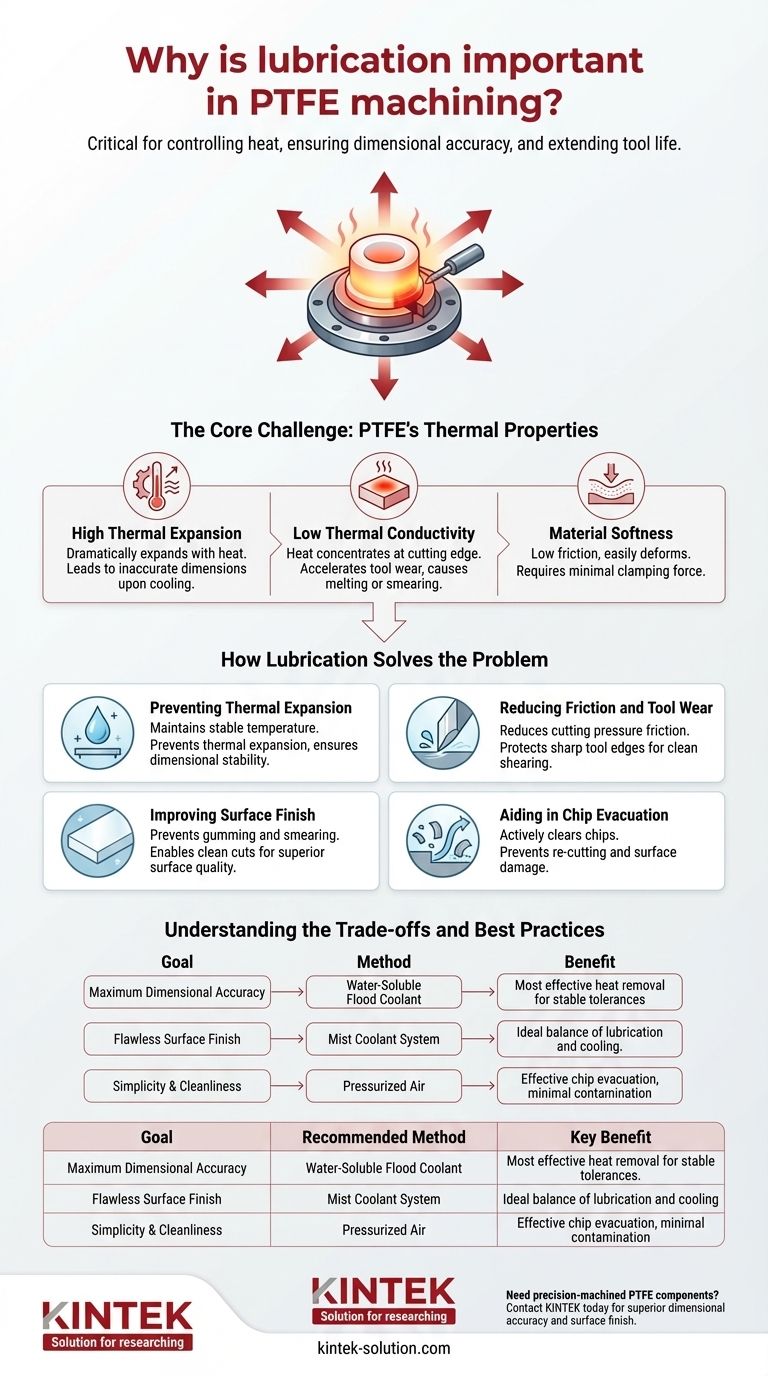

The Core Challenge: PTFE's Thermal Properties

To understand the role of lubrication, you must first understand the material itself. PTFE (Polytetrafluoroethylene) presents unique challenges that are fundamentally tied to heat management.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion. This means it expands and contracts dramatically with even small changes in temperature.

Heat generated from cutting friction will cause the material to expand mid-process, leading to inaccurate dimensions once it cools down to its final state.

Low Thermal Conductivity

The material does not dissipate heat well. Instead of spreading out, heat concentrates right at the cutting edge.

This localized heat buildup accelerates tool wear and can even cause the PTFE to melt or smear, resulting in a poor surface finish.

Material Softness

PTFE is an exceptionally soft and low-friction material. While this makes it easy to cut, it also means the material can easily deform or compress under pressure.

This property complicates fixturing, requiring minimal clamping force, and makes the part susceptible to being "pushed" by a dull tool rather than being cleanly sheared.

How Lubrication and Coolants Solve the Problem

Lubrication, more accurately termed "coolant" in this context, directly counteracts the challenges posed by PTFE's properties.

Preventing Thermal Expansion

The single most important function of a coolant is to carry heat away from the workpiece and the tool.

By maintaining a stable temperature, the coolant ensures the part's dimensional stability, preventing it from expanding during the cut and shrinking out of tolerance afterward.

Reducing Friction and Tool Wear

While PTFE is naturally low-friction, the intense pressure at the cutting edge still generates friction and heat.

A proper lubricant or coolant reduces this friction, which protects the sharp cutting edge of the tool. A sharp tool is essential for shearing the material cleanly instead of deforming it.

Improving Surface Finish

A cool, lubricated cut is a clean cut. Coolants prevent the material from becoming gummy or smearing across the surface.

Certain methods, like mist systems or dry lubricants, can significantly improve the final surface quality by ensuring a smooth shearing action.

Aiding in Chip Evacuation

Coolants, particularly pressurized air or flood systems, actively clear chips away from the cutting area.

This prevents chips from being recut, which would otherwise generate more heat and potentially mar the surface of the part.

Understanding the Trade-offs and Best Practices

Simply applying any lubricant is not enough; the method must match the goal. In fact, incorrect application can create new problems.

The Risk of Over-Lubrication

Using excessive liquid coolants or overly viscous lubricants can sometimes cause issues.

For example, too much lubrication can lead to tool slippage, especially with smaller tools, or can make it difficult to securely hold the low-friction workpiece.

Choosing the Right Coolant

The most common and effective methods are purpose-driven:

- Pressurized Air: Excellent for chip evacuation and providing moderate cooling. It's clean and ideal for applications where liquid contamination is a concern.

- Mist Systems: A step up from air, providing more active cooling with a minimal amount of liquid coolant, which helps improve surface finish.

- Water-Soluble Coolants: For aggressive or deep cuts that generate significant heat, a flood of water-soluble coolant is the most effective method for maximizing heat removal and ensuring dimensional accuracy.

It's More Than Just Coolant

Effective lubrication is part of a system. It works best when combined with other best practices for machining PTFE.

This includes using extremely sharp tools with high rake and clearance angles, employing slow feed rates to minimize heat generation, and performing thorough deburring after the process is complete.

Making the Right Choice for Your Goal

The optimal cooling strategy depends entirely on the specific requirements of your part.

- If your primary focus is maximum dimensional accuracy: Use a water-soluble flood coolant to remove heat as effectively as possible.

- If your primary focus is a flawless surface finish: A mist coolant often provides the best balance of lubrication and cooling without excess fluid.

- If your primary focus is simplicity and cleanliness: Use a steady stream of pressurized air to clear chips and provide basic cooling for less demanding cuts.

Ultimately, mastering PTFE machining is mastering thermal management.

Summary Table:

| Goal | Recommended Lubrication/Coolant Method | Key Benefit |

|---|---|---|

| Maximum Dimensional Accuracy | Water-Soluble Flood Coolant | Most effective heat removal for stable tolerances |

| Flawless Surface Finish | Mist Coolant System | Ideal balance of lubrication and cooling |

| Simplicity & Cleanliness | Pressurized Air | Effective chip evacuation, minimal contamination |

Need precision-machined PTFE components that meet your exact specifications?

At KINTEK, we specialize in machining PTFE (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in thermal management and advanced cooling techniques ensures your parts are manufactured with superior dimensional accuracy and surface finish.

We provide custom fabrication from prototypes to high-volume orders, prioritizing precision in every detail.

Contact us today to discuss your project and experience the KINTEK difference!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What maintenance advantages do PTFE compensators offer? Maximize Uptime with Self-Cleaning Design

- What makes PTFE an ideal sealing material overall? Superior Performance in Extreme Conditions

- What makes PTFE gaskets suitable for the food industry? Ensure Purity and Compliance

- How does CAD/CAM software enhance the precision of CNC machined PTFE parts? Master Digital Machining for Flawless Components

- What are the aerospace and defense applications of PTFE? Essential for Extreme Reliability

- What factors should engineers consider when selecting a PTFE rotary seal? Ensure Long-Term Reliability for Your System

- What are the key advantages of PTFE slide bearings in construction? Achieve Maintenance-Free Structural Movement

- What are the key applications of Teflon bellow mechanical seals in pulp and paper manufacturing? Enhance Reliability & Cut Downtime