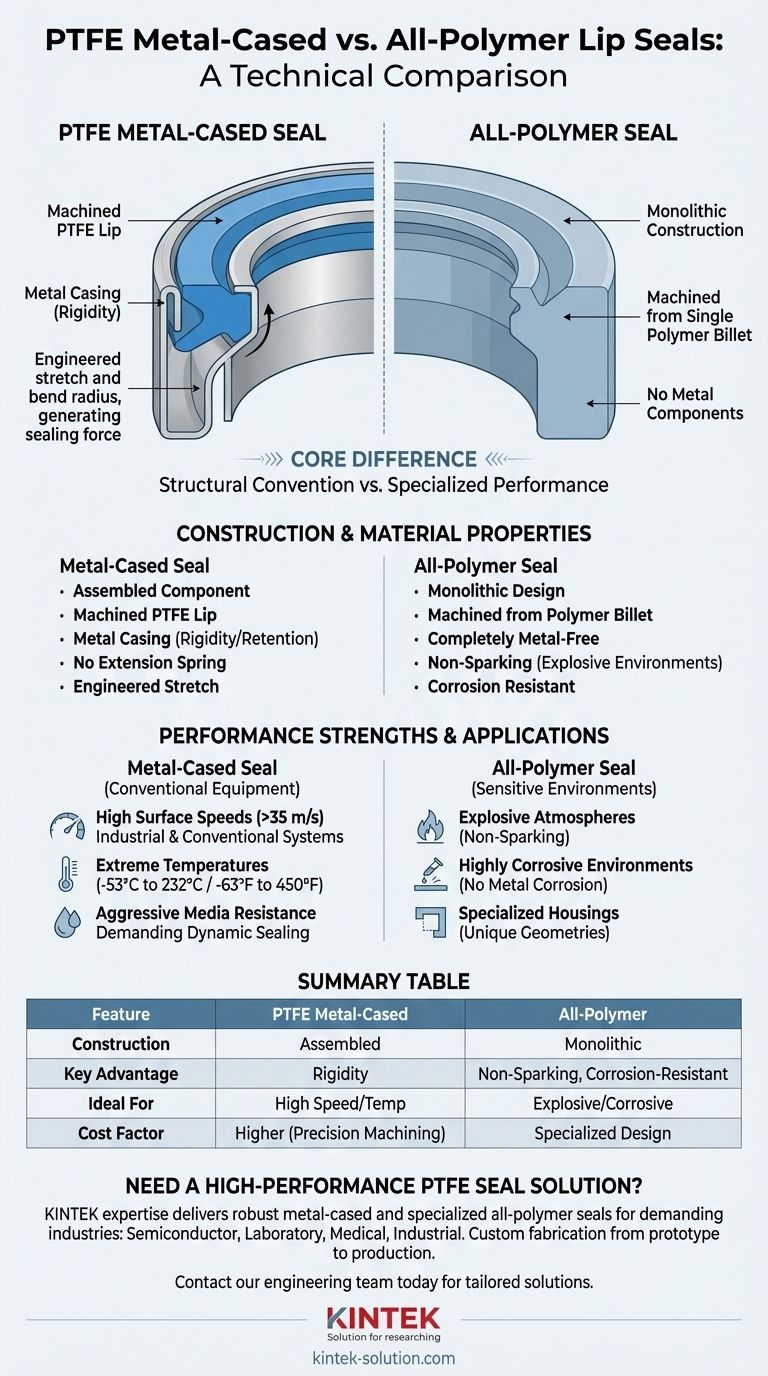

At a fundamental level, the two primary types of advanced lip seals are PTFE metal-cased seals and all-polymer seals. The core difference lies in their construction: metal-cased seals consist of a machined PTFE sealing lip assembled into a structural metal casing, whereas all-polymer seals are machined entirely from a single piece of polymer material with no metal components.

Your choice between a metal-cased seal and an all-polymer seal is a decision between structural convention and specialized performance. The metal case provides rigidity for traditional installations, while the all-polymer design eliminates metal entirely for applications where it would be a point of failure.

Deconstructing the Two Seal Designs

Understanding the physical construction of each seal type is the key to appreciating their distinct performance characteristics and ideal use cases.

The PTFE Metal-Cased Seal

A metal-cased seal is a composite component. It features a sealing element, or "lip," that has been precisely machined from a material like PTFE.

This machined lip is then press-fitted into a formed sheet metal casing. This casing provides the structural rigidity needed for installation and retention in the housing.

Unlike many common elastomeric seals, these designs typically do not use an extension spring. Instead, they rely on the engineered stretch of the lip and the bend radius of the metal casing to generate the necessary sealing force.

The All-Polymer Seal

The all-polymer seal represents a more specialized design philosophy. The entire seal, including its body and sealing lip, is machined from a single billet of high-performance polymer.

This monolithic construction completely eliminates metal from the seal assembly.

This design was originally developed for sensitive military applications where any metal-to-metal contact could create a dangerous spark in an explosive atmosphere.

Why Construction Method Matters

The material properties of PTFE are the driving force behind these distinct manufacturing processes, which directly influence both performance and cost.

The Challenge of PTFE

PTFE is a fluoropolymer known for its exceptional chemical resistance and temperature range, but it is not a material that can be injection molded.

This limitation prevents it from being directly molded onto a metal case, a common and cost-effective method used for standard elastomeric seals.

The Impact on Precision and Cost

Consequently, the PTFE lip must be machined as a separate, high-precision component before being assembled into its casing.

This multi-step process of machining and precision press-fitting is inherently more complex and costly than a single molding operation. Both the higher cost of the raw PTFE material and the machining expenses contribute to the premium price of these seals.

Understanding the Performance Trade-offs

The distinct construction of each seal type creates a clear division in their ideal operating environments.

Strengths of Metal-Cased PTFE Seals

Metal-cased PTFE seals are the go-to solution for pushing the boundaries of dynamic sealing in conventional equipment.

They excel in applications involving:

- High Surface Speeds: Capable of performing reliably at speeds exceeding 35 m/s.

- Extreme Temperatures: Maintain integrity and performance across a vast range, from -53°C to 232°C (-63°F to 450°F).

- Aggressive Media: The inherent inertness of PTFE makes it resistant to chemicals and fluids that would degrade standard elastomers.

The Advantage of the All-Polymer Design

The primary benefit of the all-polymer seal is the complete absence of metal. This makes it the superior choice when the metal casing itself would be a liability.

Key applications include:

- Explosive Atmospheres: Non-sparking properties are critical for safety.

- Highly Corrosive Environments: Eliminates the risk of the metal case corroding when exposed to aggressive chemicals.

- Specialized Housings: Can be designed for unique geometries where a standard metal case would not fit.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the seal's fundamental design to the primary demands of your system.

- If your primary focus is high-speed or high-temperature performance in standard equipment: The robust, proven design of a PTFE metal-cased seal is your most reliable choice.

- If your primary focus is safety in explosive environments or compatibility with extremely corrosive media: The all-polymer seal is the only option that completely eliminates the risks associated with a metal component.

- If your primary focus is a cost-sensitive, general-purpose application: A traditional elastomeric lip seal, which can be molded directly to its case, is often the more economical solution.

Understanding this distinction between assembled and monolithic seal construction empowers you to specify a solution that ensures both safety and long-term reliability.

Summary Table:

| Feature | PTFE Metal-Cased Seal | All-Polymer Seal |

|---|---|---|

| Construction | Machined PTFE lip assembled into a metal casing | Machined entirely from a single polymer piece |

| Key Advantage | Structural rigidity for high-speed/high-temperature applications | Non-sparking, corrosion-resistant, no metal components |

| Ideal For | Conventional equipment, extreme temperatures (up to 450°F), high speeds | Explosive atmospheres, highly corrosive environments, specialized housings |

| Cost Factor | Higher due to precision machining and assembly | Specialized design for specific safety/performance needs |

Need a High-Performance PTFE Seal Solution?

Whether your application demands the robust performance of a metal-cased PTFE seal or the specialized safety of an all-polymer design, KINTEK has the expertise to deliver.

We manufacture precision PTFE components—including seals, liners, and labware—for the most demanding industries:

- Semiconductor and Laboratory equipment requiring extreme chemical resistance

- Medical and Industrial applications needing reliable, long-lasting performance

- Specialized industries where non-sparking or corrosive-resistant properties are critical

Our custom fabrication services ensure you get the exact seal you need, from initial prototypes to high-volume production runs. We prioritize precision and performance in every component.

Contact our engineering team today to discuss your specific requirements and get a solution tailored to your application's unique challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications