In short, rotary shaft seals are essential components used across a vast range of industries to contain lubricants and prevent contaminants from entering machinery where a shaft rotates. Their applications span from automotive engines and aircraft components to the compressors, pumps, and mixers used in chemical processing, energy production, and food manufacturing.

The core purpose of a rotary shaft seal is to manage the boundary between a rotating part and a stationary housing, preventing leaks and contamination. The specific application—from a car's transmission to a pharmaceutical mixer—determines the required seal design and material, with high-performance options like PTFE being critical for harsh operating conditions.

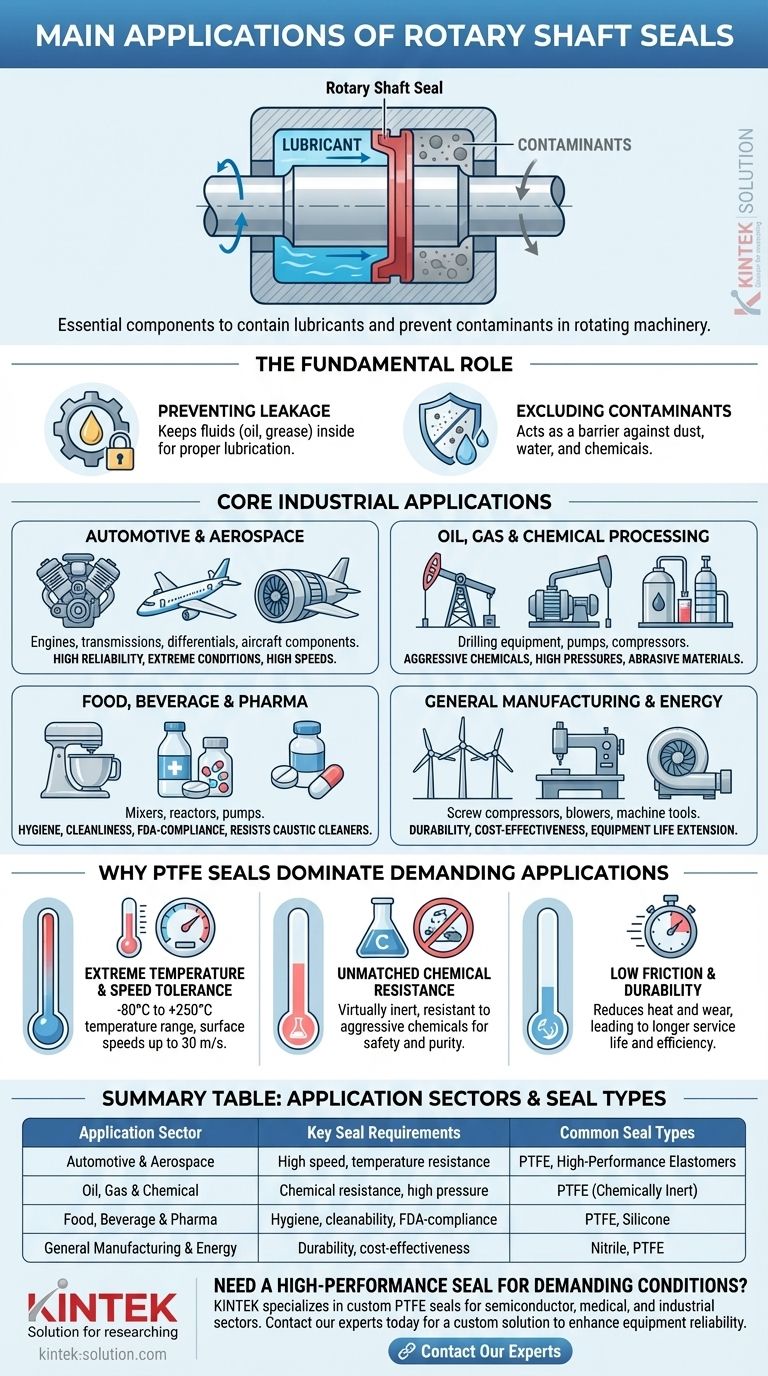

The Fundamental Role of a Rotary Shaft Seal

A rotary shaft seal is designed to solve a fundamental engineering challenge: how to seal a moving, circular shaft as it passes through a stationary housing. Without an effective seal, lubricants would leak out, and dirt, moisture, and other contaminants would get in, leading to premature equipment failure.

Preventing Leakage

The primary job is to keep fluids, such as oil or grease, inside the equipment. This ensures proper lubrication of bearings and gears.

Excluding Contaminants

The seal also acts as a barrier, stopping external contaminants like dust, water, and process chemicals from entering the machinery and compromising its internal components.

Core Industrial Applications

The versatility and reliability of rotary shaft seals make them indispensable in numerous sectors. The choice of seal is dictated by the specific demands of the environment, such as temperature, pressure, rotational speed, and chemical exposure.

Automotive and Aerospace

These industries demand high reliability under extreme conditions. Seals are used in engines, transmissions, differentials, and aircraft engine components where high rotational speeds and significant temperature fluctuations are common.

Oil, Gas, and Chemical Processing

This is one ofthe most demanding environments. Seals are critical in drilling equipment, pumps, valves, and compressors that handle aggressive chemicals, high pressures, and abrasive materials.

Food, Beverage, and Pharmaceutical

Hygiene and cleanliness are paramount in these sectors. Seals used in mixers, reactors, and pumps must prevent contamination of the product while also resisting the caustic cleaning agents used for sterilization.

General Manufacturing and Energy

Seals are foundational components in a wide array of industrial machinery. This includes screw compressors, blowers, machine tools, wind turbines, and fluid handling systems, where they extend equipment life and reduce maintenance.

Why PTFE Seals Dominate Demanding Applications

While many materials are used for seals, Polytetrafluoroethylene (PTFE) is often specified for the most challenging applications. This is due to a unique combination of material properties that standard elastomer seals cannot match.

Extreme Temperature and Speed Tolerance

PTFE seals operate effectively in a wide temperature range, typically from -80°C to +250°C. They are also designed for high-performance equipment with surface speeds up to 30 m/s.

Unmatched Chemical Resistance

PTFE is virtually inert, making it resistant to a wide range of aggressive chemicals. This property is non-negotiable in chemical processing and pharmaceutical applications where seal integrity is critical for safety and product purity.

Low Friction and Durability

The low-friction properties of PTFE reduce heat generation and wear, even in poorly lubricated conditions. This leads to longer service life, less downtime, and improved energy efficiency for the equipment.

Understanding the Trade-offs

Choosing the right seal requires balancing performance with operational needs. While a high-performance PTFE seal offers superior capabilities, it is not always the necessary or most cost-effective solution.

Material Selection vs. Application Demands

A simple water pump operating at ambient temperature does not require a seal designed for a high-speed aerospace gearbox. Over-specifying a seal increases initial cost without providing a tangible benefit.

Installation and Handling

High-performance seals, particularly those with rigid PTFE lips, can require more careful installation procedures than flexible elastomeric seals to avoid damage and ensure proper function.

Cost vs. Equipment Lifespan

The higher upfront cost of a premium seal is often justified by reduced maintenance, less frequent replacement, and the prevention of catastrophic equipment failure. The key is to evaluate the total cost of ownership, not just the initial purchase price.

Making the Right Choice for Your Goal

Your primary operational challenge will guide your seal selection.

- If your primary focus is aggressive chemicals or high temperatures: A PTFE rotary shaft seal is the default choice due to its superior chemical inertness and wide operating temperature range.

- If your primary focus is high rotational speed: Select a seal designed for low friction and heat generation, such as a PTFE lip seal, to ensure durability and performance.

- If your primary focus is hygiene and sanitation: You need a seal made from FDA-compliant materials that can withstand rigorous cleaning cycles without degrading or contaminating the product.

- If your primary focus is general-purpose industrial machinery: A standard elastomeric or nitrile seal may be perfectly adequate and more cost-effective for moderate temperatures, speeds, and non-corrosive fluids.

Ultimately, selecting the correct rotary shaft seal is a critical decision that directly impacts the reliability and lifespan of your equipment.

Summary Table:

| Application Sector | Key Seal Requirements | Common Seal Types |

|---|---|---|

| Automotive & Aerospace | High speed, temperature resistance | PTFE, High-Performance Elastomers |

| Oil, Gas & Chemical | Chemical resistance, high pressure | PTFE (Chemically Inert) |

| Food, Beverage & Pharma | Hygiene, cleanability, FDA-compliance | PTFE, Silicone |

| General Manufacturing & Energy | Durability, cost-effectiveness | Nitrile, PTFE |

Need a high-performance seal for demanding conditions?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom rotary shaft seals for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures a seal that delivers superior chemical resistance, operates across extreme temperatures (-80°C to +250°C), and withstands high speeds.

Let us help you enhance your equipment's reliability and lifespan. Contact our experts today for a custom solution tailored to your application's specific challenges.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance