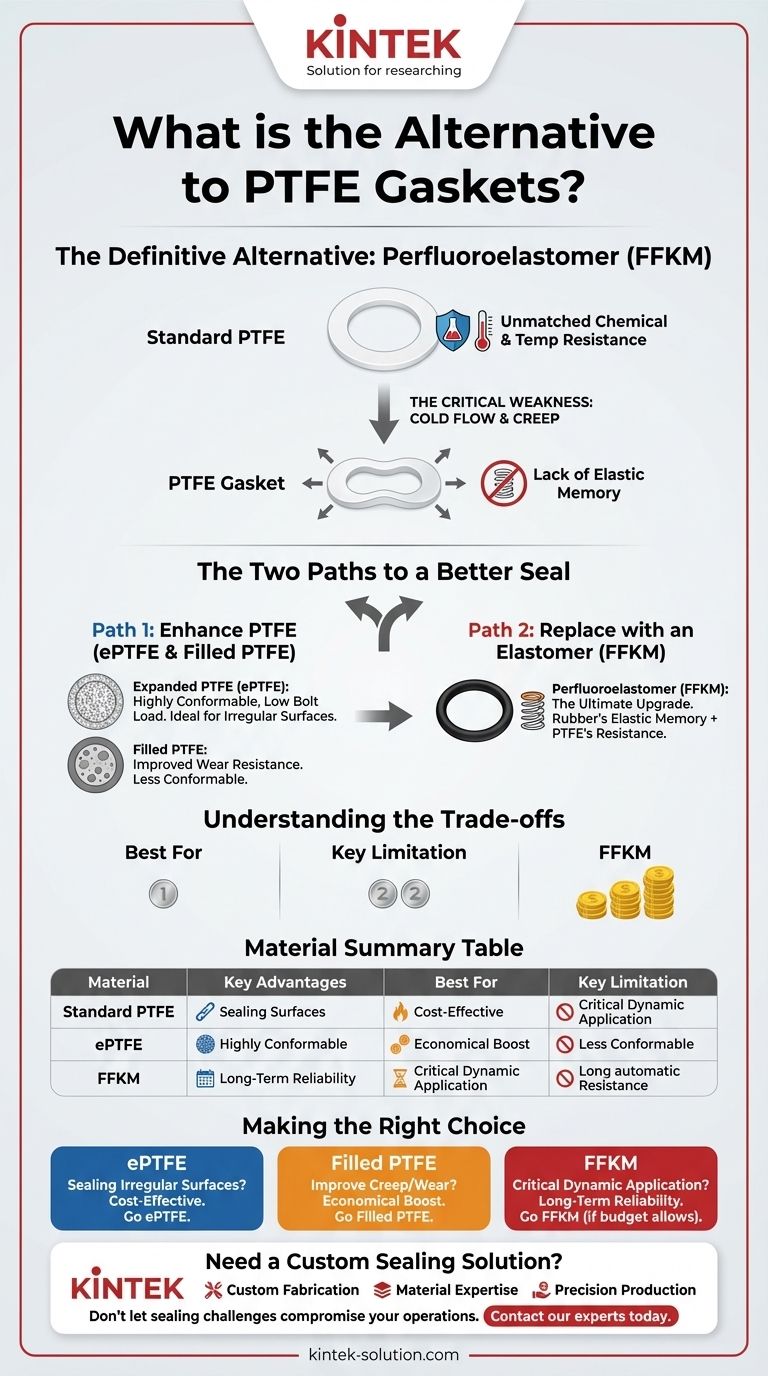

For a gasket that combines the benefits of PTFE with superior sealing properties, the definitive alternative is Perfluoroelastomer (FFKM). While standard PTFE offers unmatched chemical and temperature resistance, its plastic nature can lead to sealing issues over time. FFKM provides the same elite resistance but adds the elastic memory of rubber, ensuring a more resilient and long-lasting seal in demanding applications.

The core issue with standard PTFE is its lack of elasticity; it deforms under pressure without springing back, a problem known as "cold flow." To get a better seal, you must either enhance PTFE's structure to make it more conformable (like Expanded PTFE) or switch to a material that is inherently elastic while retaining chemical inertness (FFKM).

Why Standard PTFE Gaskets Can Fail

The Strengths: Unmatched Resistance

Standard Polytetrafluoroethylene (PTFE) is chosen for its powerful combination of properties. It is nearly inert to all chemicals and can operate in extreme temperatures, from -200°C to +260°C.

Its extremely low coefficient of friction and non-stick surface make it a uniquely reliable material for preventing leaks and reducing maintenance in everything from chemical processing to food production.

The Critical Weakness: Cold Flow and Creep

The primary weakness of standard PTFE as a sealant is cold flow, or creep. Because PTFE is a plastic, not a rubber, it will slowly and permanently deform when placed under compressive load.

This means that over time, the gasket can thin out, causing the initial bolt torque to loosen and the sealing pressure to drop, which inevitably leads to leaks.

The Lack of Elastic "Memory"

This tendency to creep is a function of PTFE's poor elastic memory. Unlike an elastomer (rubber) that springs back to its original shape after being compressed, a standard PTFE gasket does not.

This makes it less effective in applications with pressure or temperature cycling, as it cannot adapt to the changing dimensions of the flange surfaces, compromising the seal's integrity.

The Two Paths to a Better Seal

To overcome the limitations of standard PTFE, you have two primary options: enhance the PTFE itself or replace it with a true elastomer that has similar properties.

Path 1: Enhancing PTFE for Better Sealing

The most common enhancement is Expanded PTFE (ePTFE). This material is created by stretching standard PTFE, which creates a soft, porous, and fibrous structure.

This new structure is highly compressible and conformable. It easily fills in flange imperfections and creates a tight seal with much lower bolt load, directly addressing the sealing weakness of standard PTFE while retaining its chemical and thermal benefits.

Another option is filled PTFE, where additives like glass fiber, carbon, or graphite are blended in. These fillers primarily improve wear resistance and reduce cold flow but do not add the conformability of ePTFE.

Path 2: Replacing PTFE with an Elastomer (FFKM)

Perfluoroelastomer (FFKM) is the ultimate upgrade for sealing. It is an elastomer, giving it the resilience and elastic memory of rubber.

Crucially, FFKM has a chemical structure very similar to PTFE, granting it nearly identical chemical inertness and high-temperature performance. It effectively combines the best properties of PTFE (resistance) with the best properties of rubber (sealing ability).

Understanding the Trade-offs

Choosing the right material requires balancing performance needs against practical constraints. The best choice is not always the most advanced one.

When Expanded PTFE (ePTFE) is the Superior Choice

ePTFE is the ideal solution for sealing old, damaged, or irregular flange surfaces. Its exceptional softness and conformability create a reliable seal where a rigid material would fail. It is the go-to for static applications requiring high chemical resistance without the extreme cost of FFKM.

When FFKM is the Necessary Upgrade

FFKM is designed for the most demanding applications. If your system involves dynamic movement, pressure cycling, or requires a long-term, fire-and-forget seal with no chance for re-torquing, FFKM's elastic recovery makes it the only reliable choice. It is primarily used for critical O-rings and custom seals where failure is not an option.

The Deciding Factor: Cost

The most significant trade-off is cost. ePTFE is a cost-effective upgrade over standard PTFE. FFKM, due to its complex manufacturing process, is a premium material and can be an order of magnitude more expensive than any form of PTFE. Its use is typically justified only by the extreme cost of potential seal failure.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your operating environment.

- If your primary focus is sealing irregular surfaces with broad chemical resistance: Expanded PTFE (ePTFE) is your most effective and cost-efficient solution.

- If your primary focus is improving the creep and wear resistance of standard gaskets: A filled PTFE gasket offers a targeted and economical performance boost.

- If your primary focus is achieving a resilient, long-term seal in a critical dynamic application: Perfluoroelastomer (FFKM) is the definitive engineering choice, provided the budget allows for it.

Ultimately, a successful seal comes from precisely matching the material's properties to the specific challenges of your application.

Summary Table:

| Material | Key Advantages | Best For | Key Limitation |

|---|---|---|---|

| Standard PTFE | Excellent chemical resistance, high temperature tolerance | Static applications with minimal pressure cycling | Prone to cold flow, lacks elastic memory |

| Expanded PTFE (ePTFE) | High conformability, seals irregular surfaces, retains PTFE resistance | Cost-effective upgrade for damaged flanges, static seals | Not ideal for dynamic applications |

| FFKM | Combines PTFE's chemical resistance with rubber's elasticity, superior for dynamic seals | Critical applications with pressure/temperature cycling, O-rings | Significantly higher cost |

| Filled PTFE | Improved wear resistance, reduced cold flow | Applications requiring enhanced mechanical properties | Less conformable than ePTFE |

Need a Custom Sealing Solution?

Struggling with gasket failure in demanding environments? KINTEK specializes in manufacturing high-performance PTFE components, including custom seals, gaskets, and liners for semiconductor, medical, laboratory, and industrial applications.

We offer:

- Custom Fabrication: From prototypes to high-volume orders, tailored to your exact specifications.

- Material Expertise: Guidance on selecting the right material (PTFE, ePTFE, or advanced alternatives) for your unique operating conditions.

- Precision Production: Ensuring reliable, long-lasting seals that withstand extreme chemicals, temperatures, and pressures.

Don't let sealing challenges compromise your operations. Contact our experts today to discuss your application and receive a tailored solution that delivers superior performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support