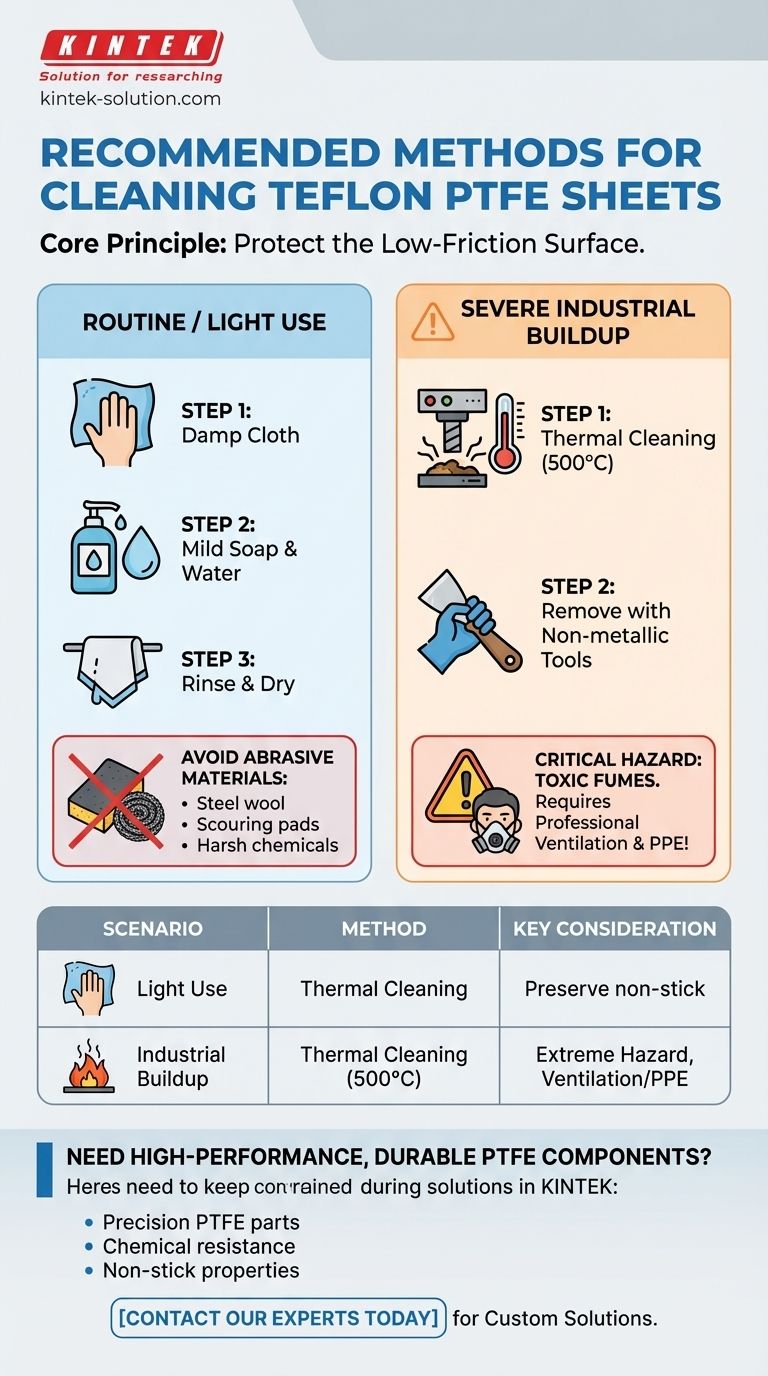

For routine cleaning of Teflon PTFE sheets, the recommended method is to simply wipe the surface with a damp cloth. If you encounter more stubborn residue, a gentle solution of mild soap and water is all that is required. The key is to use the least aggressive method possible to preserve the sheet's non-stick properties.

The core principle of cleaning PTFE is to protect its unique low-friction surface. Because materials don't easily adhere to it, aggressive scrubbing or harsh chemicals are not only unnecessary but can cause permanent damage, compromising the very properties you rely on.

The Principle of PTFE Care: Preserve the Surface

Polytetrafluoroethylene (PTFE), the compound behind the Teflon brand, is prized for its extremely low coefficient of friction and chemical inertness. Effective cleaning is about working with these properties, not against them.

Why Gentle Methods Work Best

The non-stick quality of PTFE means that most substances release with minimal effort. The surface is non-porous, so dirt and grime sit on top rather than soaking in, making them easy to remove.

The Standard Cleaning Protocol

For the vast majority of applications, a simple two-step process is sufficient. First, use a clean, damp cloth to wipe away any loose residue. For anything that remains, apply a small amount of mild dish soap to the cloth, wipe the area, and then rinse thoroughly with a clean, damp cloth to remove any soap film.

What to Categorically Avoid

Never use abrasive materials like steel wool, scouring pads, or abrasive cleaners on a PTFE surface. These will create microscopic scratches that destroy the non-stick finish and can cause materials to adhere to the sheet in the future.

Industrial Cleaning and Maintenance

In demanding industrial settings, such as removing hardened polymer residue from machinery, more intensive methods may be required. These are specialized processes and are not intended for general-purpose sheet cleaning.

Thermal Cleaning: An Industrial Method

For thick, caked-on residue on machine parts, a high-temperature decomposition method can be used. This involves carefully heating the component to approximately 500°C (932°F) to soften the PTFE. Once softened, it can be removed with non-metallic tools like brass scrapers.

Critical Safety Warning: Toxic Fumes

This thermal method is extremely hazardous if not done correctly. At high temperatures, PTFE can decompose and release toxic fluorinated compounds. This process must be performed in an area with robust, professional-grade ventilation, and operators must use appropriate personal protective equipment (PPE).

Proper Storage and Handling

To maximize the life of your PTFE sheets, always clean them after use. Store them flat or loosely rolled in a clean, dry environment away from direct sunlight or sources of heat to maintain their integrity and prevent warping.

Making the Right Choice for Your Application

Your cleaning method should always match your use case and prioritize the longevity of the material.

- If your primary focus is food preparation, lab work, or craft applications: Stick to wiping with a damp cloth and using mild soap and water only when necessary.

- If your primary focus is heavy industrial use with severe buildup on machinery: The thermal cleaning method may be necessary, but it must be performed by trained personnel with stringent safety protocols in place.

Ultimately, treating the PTFE surface with care is the best way to ensure it performs reliably over its entire lifespan.

Summary Table:

| Cleaning Scenario | Recommended Method | Key Considerations |

|---|---|---|

| Routine / Light Use | Damp cloth; mild soap and water if needed. | Preserves the non-stick surface. Avoid abrasives. |

| Severe Industrial Buildup | Specialized thermal cleaning (~500°C / 932°F). | Extreme Hazard: Requires professional ventilation and PPE due to toxic fumes. |

Need High-Performance, Durable PTFE Components?

Proper cleaning extends the life of your PTFE, but starting with a high-quality component is the real key to long-term performance. At KINTEK, we specialize in manufacturing precision PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize material integrity in our production process, ensuring your components offer superior chemical resistance and non-stick properties from the start. Whether you need prototypes or high-volume orders, our custom fabrication service delivers reliable solutions.

Let us provide the durable PTFE components your application demands. Contact our experts today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the primary applications of PTFE PCBs? The Ultimate Guide for High-Frequency & Harsh Environments

- What are the advantages of using a Teflon sheet for heat press? Protect Your Projects & Achieve Flawless Results

- What are the characteristics of PTFE spherical balls? Key Properties for Demanding Applications

- What advantages do PTFE bearings offer in aviation systems? Achieve Lighter, More Reliable Aircraft Performance

- What industries commonly use PTFE bushings? Critical Applications in Chemical, Automotive, and Medical

- What are the tensile strength properties of PTFE? Leveraging Flexibility and Chemical Resistance

- How are PTFE lip seals used in the automotive industry? Ensure Leak-Proof Performance in High-Speed, High-Temp Applications

- Are PTFE diaphragms suitable for all chemical environments? The Critical Limits You Must Know