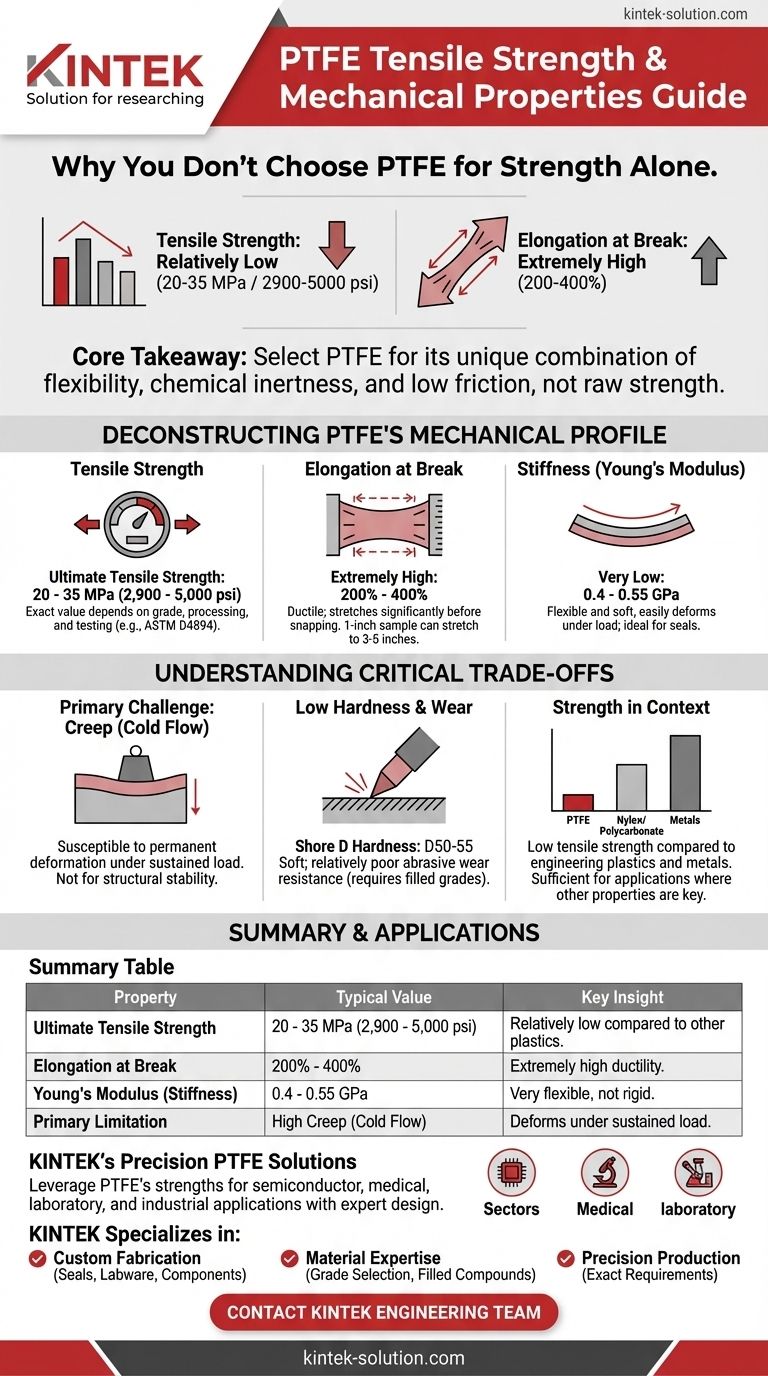

In short, the tensile strength of Polytetrafluoroethylene (PTFE) is relatively low, typically ranging from 20 to 35 MPa (2900 to 5000 psi). This moderate strength is paired with extremely high elongation, meaning the material is flexible and will stretch significantly before it breaks. Therefore, evaluating PTFE on tensile strength alone is misleading; its true value lies in its unique combination of properties.

The core takeaway is that you don't select PTFE for its strength. You select it because it combines moderate strength with exceptional chemical inertness, extreme flexibility, and one of the lowest coefficients of friction of any solid material. Its primary limitation is its tendency to deform under sustained load.

Deconstructing PTFE's Mechanical Profile

To properly evaluate PTFE, we must look beyond a single number and understand how its key mechanical properties interact. Tensile strength is just one piece of a much larger puzzle.

The Numbers: Tensile Strength

The ultimate tensile strength of pure PTFE generally falls within a consistent range.

- Megapascals (MPa): 20 - 35 MPa

- Pounds per Square Inch (psi): 2,900 - 5,000 psi

The exact value can vary based on the specific grade of the material, its processing method, and the testing standard used (e.g., ASTM D4894).

The Critical Context: Elongation at Break

PTFE's moderate tensile strength is complemented by its very high elongation at break, typically between 200% and 400%.

This means a 1-inch sample of PTFE can stretch to 3-5 inches before it snaps. It is a highly ductile material, not a brittle one. It fails by stretching and deforming, not by shattering.

Stiffness vs. Strength: Young's Modulus

PTFE has a very low Young's Modulus (a measure of stiffness), around 0.4 to 0.55 GPa.

This confirms what its high elongation suggests: PTFE is not a rigid material. It is highly flexible and will deform easily under a load, which is often a desired characteristic for applications like seals and gaskets.

Understanding the Critical Trade-offs

The unique properties of PTFE come with significant limitations that are crucial for any design consideration. Its mechanical weaknesses are just as important as its strengths.

The Primary Challenge: Creep (Cold Flow)

The most significant mechanical limitation of PTFE is its susceptibility to creep, also known as cold flow.

Under a constant, sustained load (even at room temperature), PTFE will slowly and permanently deform. This makes it unsuitable for structural applications that require long-term dimensional stability under constant stress.

Low Hardness and Wear Resistance

PTFE is a relatively soft material, with a hardness of around D50-55 on the Shore or Rockwell scale.

While its self-lubricating properties are excellent (low friction), its softness means it has relatively poor resistance to abrasive wear. In high-wear applications, filled grades of PTFE are often required.

Strength in Context

Compared to common engineering plastics like Nylon or Polycarbonate, or to any metal, PTFE's tensile strength is low.

However, its strength is more than sufficient for its intended applications, where its other properties—like surviving corrosive chemicals or providing a non-stick, low-friction surface—are the primary requirements.

Making the Right Choice for Your Application

Choosing a material requires matching its entire profile to your goal. Raw strength is rarely the only factor.

- If your primary focus is high load-bearing capacity: Pure PTFE is a poor choice due to its low strength and high potential for creep. You should consider filled PTFE grades or a different class of engineering polymer.

- If your primary focus is flexible sealing or low-friction movement: PTFE is an exceptional choice. Its ability to conform to surfaces, combined with its chemical inertness and lubricity, is unmatched.

- If your primary focus is performance in corrosive environments: PTFE is often the only viable option. Its mechanical properties are secondary to its ability to survive chemical attack that would destroy other materials.

Ultimately, you leverage PTFE not for its ability to resist force, but for its unique and powerful combination of flexibility, lubricity, and resilience.

Summary Table:

| Property | Typical Value for PTFE | Key Insight |

|---|---|---|

| Ultimate Tensile Strength | 20 - 35 MPa (2,900 - 5,000 psi) | Relatively low compared to other engineering plastics. |

| Elongation at Break | 200% - 400% | Extremely high ductility; it stretches significantly before failing. |

| Young's Modulus (Stiffness) | 0.4 - 0.55 GPa | Very flexible and soft, not a rigid material. |

| Primary Limitation | High Creep (Cold Flow) | Deforms under sustained load; not for structural applications. |

Need High-Performance PTFE Components?

PTFE's unique properties—like extreme chemical resistance, flexibility, and a low coefficient of friction—make it ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. However, its mechanical behavior requires expert design and fabrication to ensure success.

KINTEK specializes in precision PTFE manufacturing. We help you leverage PTFE's strengths while mitigating its limitations through:

- Custom Fabrication: From prototypes to high-volume production of seals, liners, labware, and complex components.

- Material Expertise: Guidance on selecting the right PTFE grade (including filled compounds) for your specific application.

- Precision Production: Ensuring your parts meet exact dimensional and performance requirements.

Let's discuss your project requirements. Contact our engineering team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the temperature range that PTFE instrumentation tube fittings can withstand? A Guide to Extreme Thermal Performance

- What are some common uses of PTFE in industries? Solve Challenges with a Versatile High-Performance Polymer

- How is PTFE applied in the medical field? Enhancing Patient Care with Biocompatible Solutions

- How do PTFE gaskets contribute to electrical insulation? Ensuring Reliability in Harsh Environments

- What considerations are important for successful PTFE CNC machining? Master Precision with a Finesse-Over-Force Approach

- What are the mechanical properties of PTFE that make it durable? Leverage Specialized Resilience

- What are the typical uses for thin PTFE washers (0.2mm – 0.5mm)? Solve Sealing, Friction & Insulation Challenges

- What types of parts can be fabricated using PTFE machining? Seals, Bushings, Insulators & More