In the automotive industry, Polytetrafluoroethylene (PTFE) lip seals are critical components used to prevent fluid leaks in high-performance and demanding environments. They are specifically engineered for systems involving high rotational speeds, extreme temperatures, and aggressive chemicals, finding use in everything from NASCAR engine crankshafts and electric vehicle e-drives to fuel injection pumps and air conditioning compressors.

The core reason for selecting PTFE lip seals is their ability to function reliably where traditional elastomer seals fail. They are not a universal replacement but a targeted solution for the most challenging sealing applications in modern vehicles, driven by heat, speed, and chemical exposure.

Why PTFE is Essential for Modern Automotive Systems

The push for greater engine efficiency, higher performance, and the unique demands of electric vehicles has expanded the role of PTFE seals. They are chosen when the operational environment exceeds the physical and chemical limits of conventional materials.

Handling Extreme Rotational Speeds

PTFE's exceptionally low coefficient of friction makes it the ideal material for high-speed rotating shafts. This property minimizes heat generation and wear, preventing premature seal failure.

You will find them in engine drive shafts for high-performance racing, turbochargers, and the rapidly spinning components within EV cooling systems and e-drive units.

Withstanding High Temperatures and Pressures

The engine compartment is an incredibly harsh environment. PTFE seals maintain their structural integrity and sealing capability at temperatures that would cause standard elastomer seals to degrade and fail.

This makes them essential for sealing engine crankshafts, where they prevent oil leaks while enduring intense heat and pressure from the combustion process.

Resisting Corrosive Fluids

Automotive systems rely on a variety of aggressive fluids, including lubricants, fuels, and coolants. PTFE is chemically inert, meaning it does not react with or degrade from exposure to these substances.

This resistance is why PTFE is used for fuel hose linings, fuel injection pump seals, and other components within fuel, hydraulic, and air conditioning systems.

Ensuring Sealing in Diverse Systems

Beyond the powertrain, PTFE lip seals are integral to the reliability of other critical vehicle functions.

They are used in steering wheel seals, braking systems, and suspension components to ensure leak-proof performance and long service life.

The Core Advantages Over Traditional Elastomers

While standard elastomer seals are suitable for many applications, PTFE provides a significant performance upgrade in several key areas, directly addressing the automotive industry's most difficult sealing challenges.

Superior Durability and Lifespan

PTFE seals offer a much longer, maintenance-free service life. In industrial applications like air compressors, they can operate for over 40,000 hours without issue.

This durability translates directly to automotive use, enhancing vehicle reliability and reducing the likelihood of costly, labor-intensive repairs due to seal failure.

Low-Friction Operation

Unlike elastomers, which can have high "stick-slip" friction, PTFE provides a smooth, low-friction surface.

This reduces the torque required to turn a shaft, which can contribute to minor gains in fuel efficiency and performance. More importantly, it dramatically reduces wear on both the seal and the shaft itself.

Performance in Abrasive Conditions

PTFE lip seals are engineered to perform reliably even in dry or abrasive environments where lubrication may be inconsistent.

This robust characteristic ensures a consistent seal in demanding conditions that could quickly destroy a less resilient material.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE offers exceptional performance, it's important to understand its specific characteristics and limitations to ensure proper application.

Installation Sensitivity

PTFE lip seals are generally more rigid than their elastomer counterparts. This means they are less forgiving of imperfections on the shaft or housing.

Proper installation technique is critical to avoid damaging the seal lip, which can create a leak path from the very beginning.

Higher Initial Cost

As a high-performance engineered material, PTFE seals typically have a higher upfront cost compared to standard elastomer seals.

This cost is justified by their extended lifespan and superior performance in applications where a failure would be catastrophic or extremely expensive to repair.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. This must be accounted for in the engineering design of the seal and the surrounding components to ensure a consistent seal is maintained across the full operating temperature range.

Making the Right Choice for Your Application

Selecting the correct sealing material requires a clear understanding of the operational demands of the specific component.

- If your primary focus is high-performance powertrains: PTFE is the definitive choice for sealing high-speed rotating shafts like crankshafts, driveshafts, and turbochargers where heat and chemical resistance are paramount.

- If your primary focus is extreme reliability: For critical systems like braking, fuel delivery, or steering where seal failure cannot be tolerated, PTFE's durability provides an essential margin of safety.

- If your primary focus is cost-sensitive, static applications: For less demanding scenarios without high speeds or extreme temperatures, traditional elastomer seals often provide a perfectly adequate and more economical solution.

Ultimately, choosing the right seal is about matching the material's capabilities to the precise performance requirements of the application.

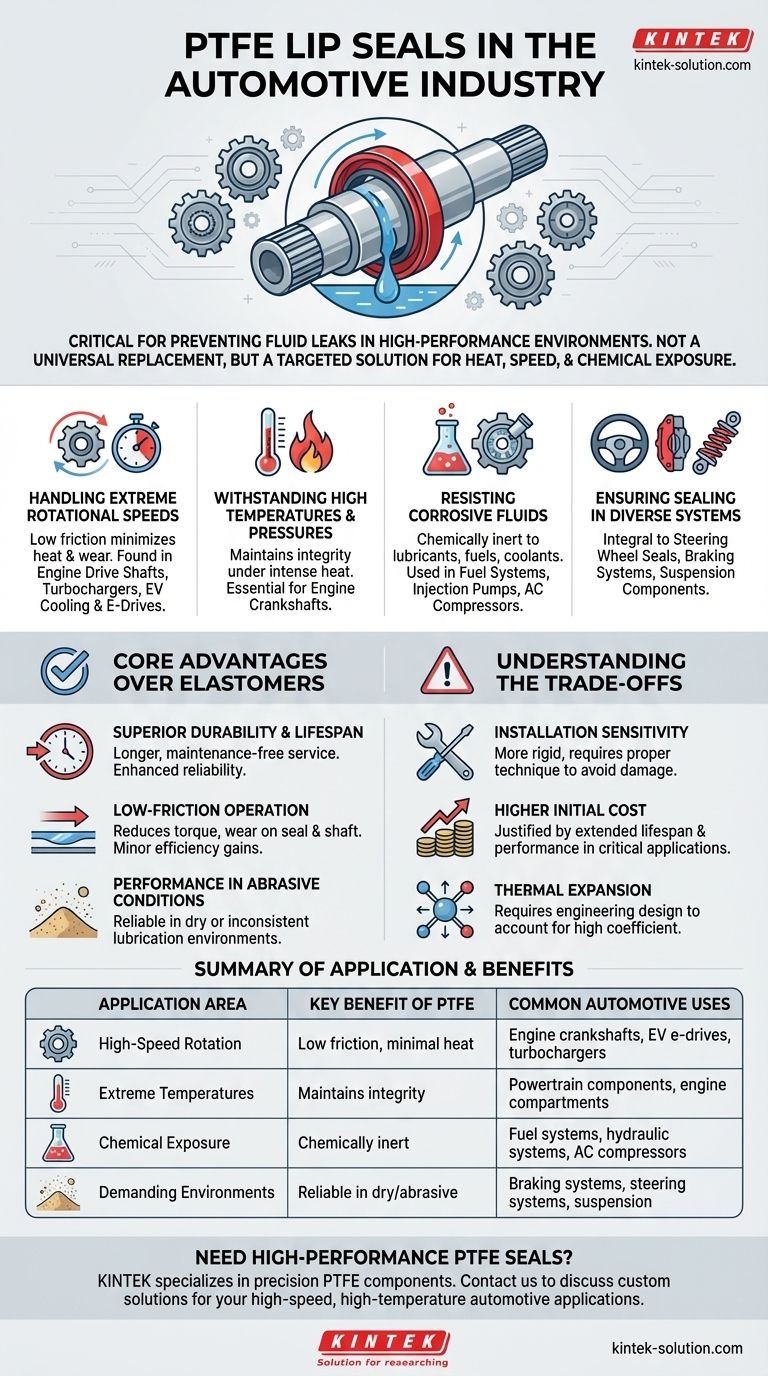

Summary Table:

| Application Area | Key Benefit of PTFE Lip Seals | Common Automotive Uses |

|---|---|---|

| High-Speed Rotation | Low friction, minimal heat generation | Engine crankshafts, EV e-drives, turbochargers |

| Extreme Temperatures | Maintains integrity under high heat | Powertrain components, engine compartments |

| Chemical Exposure | Chemically inert, resists degradation | Fuel systems, hydraulic systems, AC compressors |

| Demanding Environments | Reliable in dry or abrasive conditions | Braking systems, steering systems, suspension |

Need high-performance PTFE seals for your automotive applications? KINTEK specializes in manufacturing precision PTFE components, including custom lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get seals that meet the exact demands of high-speed, high-temperature environments. Contact us today to discuss how our PTFE solutions can enhance the reliability and durability of your automotive systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers