In aviation systems, the primary advantages of PTFE bearings are their ability to dramatically reduce friction and eliminate the need for traditional liquid lubrication. This ensures exceptionally smooth, precise, and reliable operation in critical components like aircraft control systems, landing gear, and actuators.

The fundamental value of PTFE in aviation is not just one feature, but its unique combination of properties. It acts as a self-lubricating, chemically inert, and thermally stable material, which translates directly into lower maintenance, reduced system weight, and higher operational reliability in extreme flight conditions.

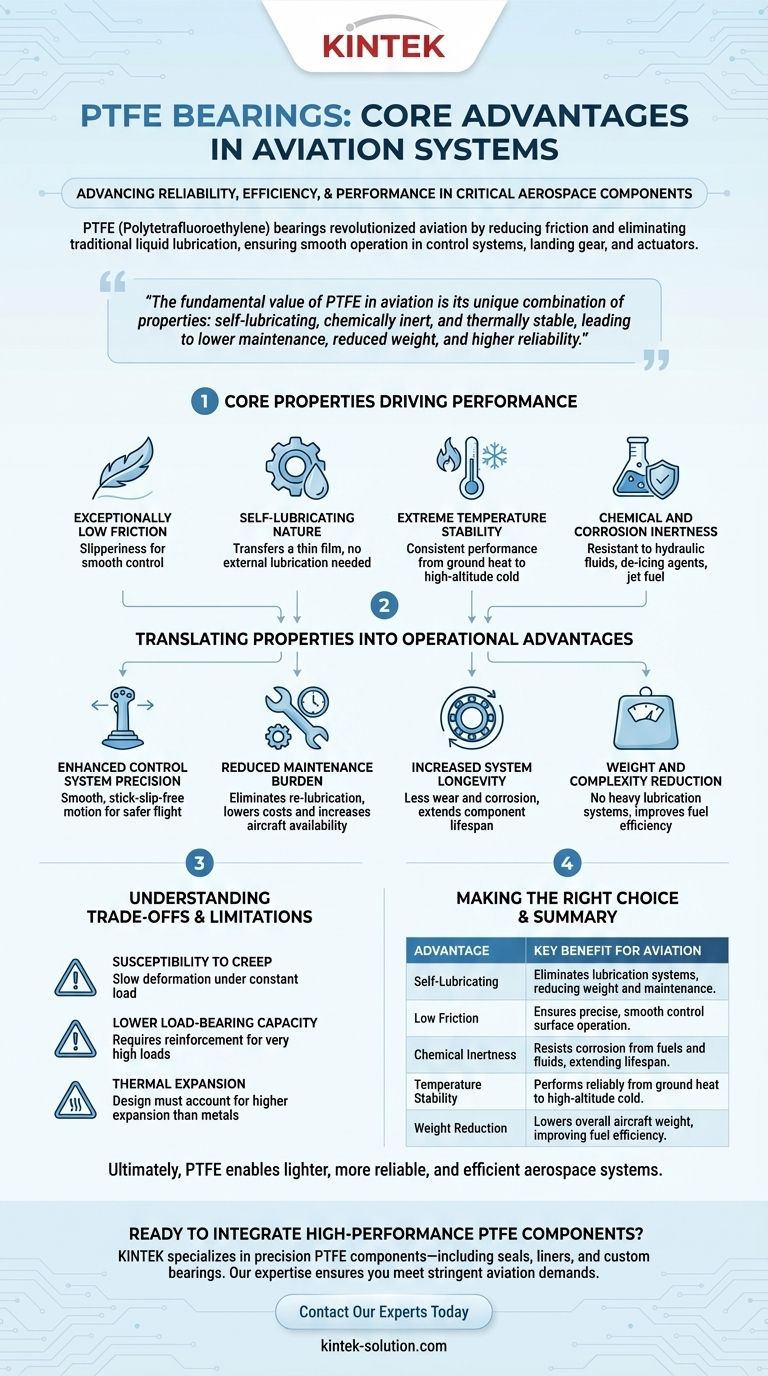

The Core Properties Driving Performance

To understand why PTFE is so valuable in aerospace, we must first look at its intrinsic material characteristics. These properties work in concert to solve multiple engineering challenges simultaneously.

Exceptionally Low Coefficient of Friction

PTFE, widely known by the brand name Teflon, has one of the lowest coefficients of friction of any solid material.

This "slipperiness" is critical for control surfaces, where any binding or "stick-slip" motion could compromise flight safety. It allows for smooth, immediate, and predictable responses to pilot or autopilot inputs.

Self-Lubricating Nature

Unlike metal bearings that require grease or oil, PTFE bearings are inherently self-lubricating. The material transfers a thin film to the mating surface, creating a durable, low-friction interface.

This eliminates the need for complex and heavy lubrication systems, including pumps, reservoirs, and lines. It also removes a common point of failure and a significant maintenance task.

Extreme Temperature Stability

Aviation systems must operate reliably from scorching ground temperatures to the freezing conditions at high altitudes.

PTFE maintains its key properties across a vast temperature range, ensuring consistent performance without becoming brittle in the cold or degrading in the heat.

Chemical and Corrosion Inertness

Aircraft are exposed to a variety of harsh substances, including hydraulic fluids, de-icing agents, and jet fuel.

PTFE is almost completely inert, meaning it will not react with or be degraded by these chemicals. This prevents corrosion-related failures and extends the lifespan of the components.

Translating Properties into Operational Advantages

These core properties deliver tangible benefits that are crucial for modern aviation design and operation.

Enhanced Control System Precision

The smooth, low-friction movement provided by PTFE bearings is essential for the precise articulation of flight controls like ailerons, elevators, and rudders. This directly contributes to safer and more stable flight characteristics.

Reduced Maintenance Burden

By eliminating the need for periodic re-lubrication, PTFE bearings significantly reduce maintenance schedules and associated labor costs. This increases aircraft availability and lowers the total cost of ownership.

Increased System Longevity

Less friction means less wear. Combined with its resistance to corrosion and chemical attack, PTFE ensures that bearing components last longer, even in high-cycle applications.

Weight and Complexity Reduction

Every pound matters on an aircraft. By removing the need for external lubrication systems, designers can reduce the overall weight and mechanical complexity of the aircraft, leading to improved fuel efficiency and reliability.

Understanding the Trade-offs and Limitations

While highly advantageous, PTFE is not a universal solution. An objective technical assessment requires understanding its limitations.

Susceptibility to Creep

Under a constant, heavy load, PTFE can slowly deform over time—a phenomenon known as "creep." This must be accounted for in the design of high-load joints.

Lower Load-Bearing Capacity

Compared to hardened steel bearings, pure PTFE has a lower compressive strength. For very high-load applications, PTFE is often used as a liner in a stronger metal housing or reinforced with fillers like glass fiber or carbon to enhance its mechanical properties.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. Engineers must carefully design the clearances and mounting methods to accommodate this expansion and prevent the bearing from binding at temperature extremes.

Making the Right Choice for Your Application

Selecting the right material is about aligning its properties with your primary engineering goal.

- If your primary focus is reliability in control systems: The ultra-low, consistent friction of PTFE is its most important advantage, ensuring stick-slip-free motion.

- If your primary focus is reducing maintenance and lifetime cost: Its self-lubricating and corrosion-resistant nature will provide the greatest return by minimizing service intervals.

- If your primary focus is performance in extreme environments: The combination of wide temperature stability and chemical inertness makes PTFE a uniquely resilient choice for exposed components.

Ultimately, understanding these principles allows engineers to build lighter, more reliable, and more efficient aerospace systems.

Summary Table:

| Advantage | Key Benefit for Aviation |

|---|---|

| Self-Lubricating | Eliminates lubrication systems, reducing weight and maintenance. |

| Low Friction | Ensures precise, smooth control surface operation. |

| Chemical Inertness | Resists corrosion from fuels and fluids, extending lifespan. |

| Temperature Stability | Performs reliably from ground heat to high-altitude cold. |

| Weight Reduction | Lowers overall aircraft weight, improving fuel efficiency. |

Ready to integrate high-performance PTFE components into your aerospace systems?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom bearings—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get components that meet the stringent demands of aviation.

Contact our experts today to discuss how our PTFE solutions can enhance your system's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support