A Teflon sheet is an essential accessory for any heat press user seeking professional and consistent results. It serves as a reusable, heat-resistant, non-stick barrier that protects your garment from scorching, prevents ink from staining your heat platen, and ensures the heat is distributed evenly for a flawless transfer.

The core function of a Teflon sheet is to create a controlled, clean, and protected environment during the heat transfer process. It's a small investment that eliminates common points of failure, safeguarding both your project materials and your equipment.

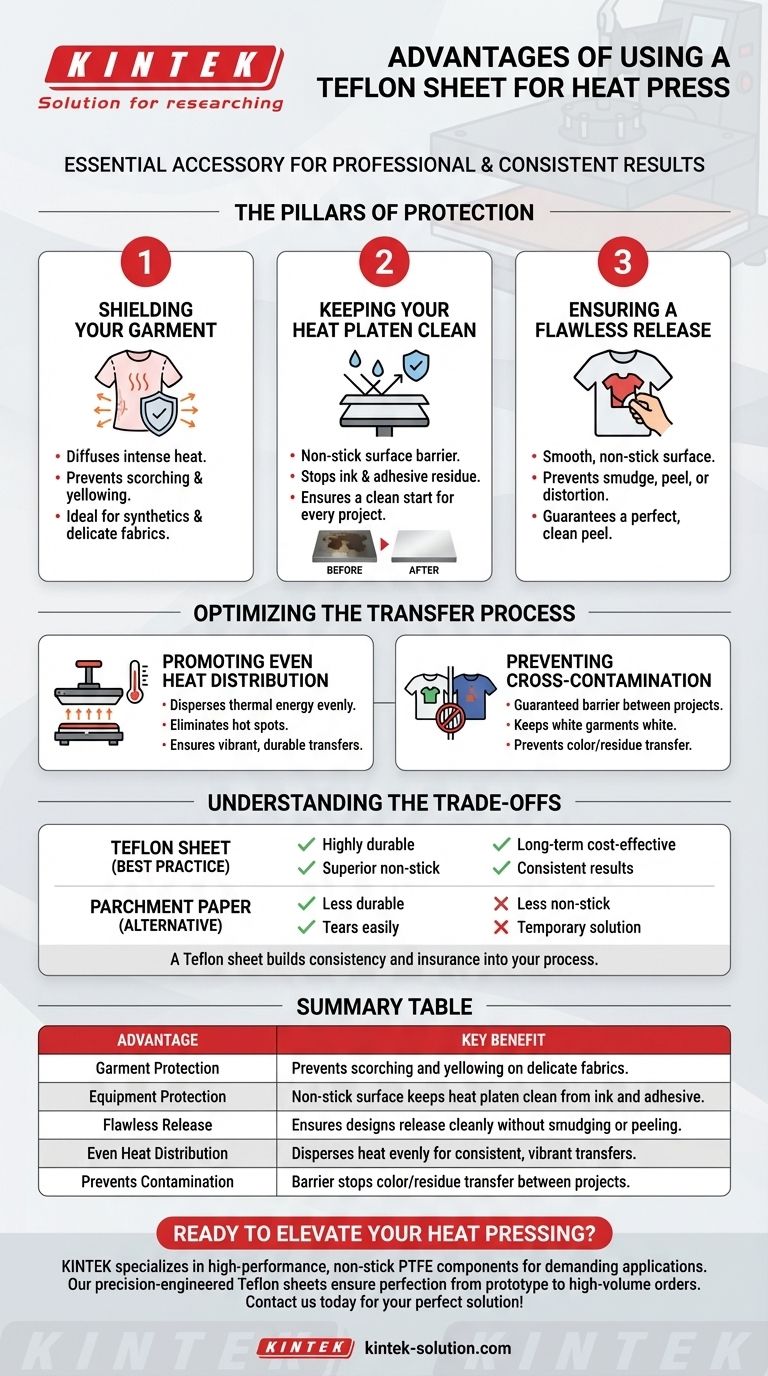

The Pillars of Protection

The primary advantages of a Teflon sheet can be understood as three distinct layers of protection that work together to guarantee a better outcome.

Shielding Your Garment from Damage

Direct contact with a hot metal platen can easily burn or discolor delicate fabrics, especially synthetics like polyester. A Teflon sheet acts as a crucial buffer.

It diffuses the intense, direct heat, significantly reducing the risk of scorching (burn marks) or yellowing on light-colored materials. This layer of protection is non-negotiable for achieving a professional finish on sensitive items.

Keeping Your Heat Platen Clean

Ink from sublimation or excess adhesive from heat transfer vinyl (HTV) can easily transfer onto your upper heat platen during pressing. This residue can then ruin subsequent projects with unwanted stains.

The non-stick surface of a Teflon sheet prevents any ink, dye, or glue from ever touching your equipment. This keeps your platen pristine, ensuring every new project starts with a clean slate.

Ensuring a Flawless, Non-Stick Release

Immediately after pressing, some vinyl or transfer papers can be slightly tacky. Pulling the garment away from a bare platen can cause the fresh design to smudge, peel, or distort.

A Teflon sheet provides a perfectly smooth and non-stick surface, guaranteeing that the garment and design release cleanly from the press every single time.

Optimizing the Transfer Process

Beyond simple protection, a Teflon sheet actively improves the quality and consistency of your heat application.

Promoting Even Heat Distribution

While a quality heat press provides consistent heat, minor variations can still occur across the platen's surface. These "hot spots" can lead to uneven transfers.

The Teflon sheet helps to disperse the thermal energy more evenly across the entire design. This ensures all parts of the transfer receive the correct temperature for the correct time, leading to a vibrant and durable application.

Preventing Cross-Contamination

If you work on multiple projects without cleaning the platen, faint colors or residues from a previous job can easily transfer to your next one.

By using a Teflon sheet as a standard part of your workflow, you create a guaranteed barrier that prevents this cross-contamination, keeping your white garments white and your colors crisp.

Understanding the Trade-offs

While highly recommended, it's important to understand the context of using a protective sheet.

Is a Teflon Sheet Always Necessary?

For some durable, light-colored cotton fabrics, you might successfully press a design without a protective sheet. However, this introduces an unnecessary risk.

Using the sheet is a best practice that builds consistency and insurance into your process. The minimal cost and effort far outweigh the potential for a ruined garment or a damaged press.

Alternatives like Parchment Paper

Parchment paper is a common, disposable alternative to a Teflon sheet. It provides a protective barrier and is inexpensive.

However, parchment paper is far less durable, tears easily, and is not as non-stick as Teflon. It is a functional substitute for occasional use but is not a reliable long-term solution for anyone serious about heat pressing.

Making the Right Choice for Your Goal

To achieve predictable, high-quality results, integrating a protective sheet into your workflow is key.

- If your primary focus is consistent, professional quality: A reusable Teflon sheet is a non-negotiable tool for protecting your work and your equipment.

- If your primary focus is working with delicate synthetics or white fabrics: Using a Teflon sheet is the only way to reliably prevent scorching and permanent yellowing.

- If your primary focus is budget and you press infrequently: High-quality parchment paper can work as a temporary solution, but a Teflon sheet is a more cost-effective investment in the long run.

Ultimately, using a protective sheet like Teflon elevates your heat pressing from a craft into a controlled and repeatable process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Garment Protection | Prevents scorching and yellowing on delicate fabrics. |

| Equipment Protection | Non-stick surface keeps heat platen clean from ink and adhesive. |

| Flawless Release | Ensures designs release cleanly without smudging or peeling. |

| Even Heat Distribution | Disperses heat evenly for consistent, vibrant transfers. |

| Prevents Contamination | Barrier stops color/residue transfer between projects. |

Ready to elevate your heat pressing with professional-grade Teflon sheets? KINTEK specializes in manufacturing high-performance, non-stick PTFE components for demanding applications. Our precision-engineered sheets are designed for durability and flawless performance, ensuring your transfers are perfect every time. Whether you need a custom size or a reliable standard product, we deliver quality from prototype to high-volume orders. Contact us today to find the perfect solution for your heat press needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the benefits of PTFE bushes being self-lubricating? Achieve Maintenance-Free, High-Efficiency Motion

- What is the purpose of a PTFE liner in spherical bearings and rod ends? Achieve Zero-Maintenance, High-Precision Motion

- What is a PTFE sliding bearing pad and where is it used? Essential for Structures & Heavy Equipment

- How do the costs of Teflon encapsulated O-rings compare to other sealing solutions? A Guide to Total Cost of Ownership

- What are the advantages of PTFE over other polymers in CNC machining? Achieve Superior Performance in Demanding Applications

- What are Teflon PTFE sheets made of and what are their key properties? Unlock Superior Performance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- Why are glass-filled PTFE rods used in aerospace? Achieve Superior Strength & Wear Resistance