The fundamental purpose of a PTFE liner in a spherical bearing or rod end is to make the component self-lubricating. This thin, durable layer is bonded to the inner surface of the bearing's outer race, creating a low-friction surface for the ball to ride on. This design completely eliminates the need for external grease or oil for the life of the bearing.

A PTFE liner transforms a standard bearing into a zero-maintenance component. It's not just about convenience; it's a design choice that enhances reliability, precision, and durability, especially in environments where traditional lubrication would fail.

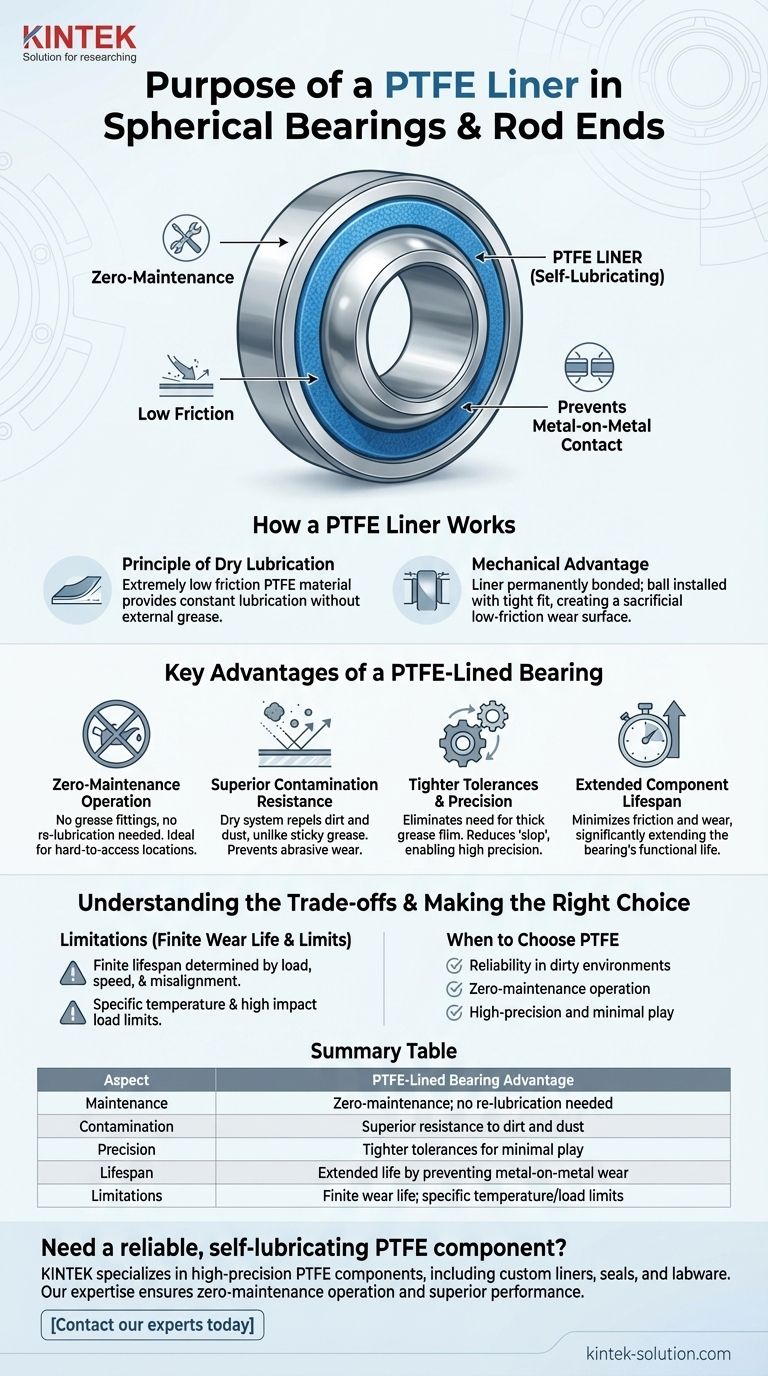

How a PTFE Liner Works

A PTFE liner isn't just a simple coating; it's an engineered system that provides constant, reliable lubrication without any external input.

The Principle of Dry Lubrication

Polytetrafluoroethylene (PTFE) is a material with an extremely low coefficient of friction. By placing this material between the two moving metal surfaces—the ball and the outer race—it prevents direct metal-on-metal contact.

As the spherical ball moves and rotates, it slides against the slick surface of the liner. This action provides a continuous lubricating effect, minimizing friction and preventing the kind of wear that would quickly destroy an unlubricated metal bearing.

The Mechanical Advantage

The liner is permanently bonded to the inner diameter of the bearing's body or outer race. The ball is then installed with a very tight fit against this liner.

This construction ensures that all movement happens between the ball and the PTFE surface, effectively turning the liner into a sacrificial, low-friction wear surface.

Key Advantages of a PTFE-Lined Bearing

Choosing a PTFE-lined bearing over a traditional greasable bearing offers several distinct operational benefits that are critical in demanding applications.

Zero-Maintenance Operation

The most obvious benefit is the elimination of maintenance. There are no grease fittings to attend to and no re-lubrication schedule to manage. This is invaluable for components in locations that are difficult to access.

Superior Contamination Resistance

Traditional grease is sticky and acts as a magnet for dirt, dust, and other abrasive particles. This mixture can form a grinding paste that accelerates wear.

Because a PTFE liner is a dry system, it does not attract contaminants, making it the superior choice for dirty or dusty environments in industries from agriculture to off-road motorsports.

Tighter Tolerances and Precision

Without the need for a thick film of grease to separate the components, PTFE-lined bearings can be manufactured with much tighter internal clearances.

This reduction in "slop" or play between the ball and the race results in more precise and predictable mechanical movement, a critical factor in high-performance automotive and aerospace applications.

Extended Component Lifespan

By preventing metal-on-metal contact and minimizing abrasive wear, the liner significantly extends the functional life of the bearing assembly.

Understanding the Trade-offs

While highly effective, PTFE liners are not a universal solution. Understanding their limitations is key to proper application.

Finite Wear Life

The PTFE liner is a wear item. While durable, it has a finite lifespan determined by load, speed, and the degree of misalignment it experiences. Once the liner is worn through, the bearing has reached the end of its life and must be replaced.

Temperature and Load Limits

PTFE has specific operating temperature limits. In applications with extreme heat, the liner can degrade. Similarly, under exceptionally high impact loads or speeds, the liner can be damaged more quickly than a system lubricated by high-pressure grease.

Making the Right Choice for Your Application

Selecting the correct bearing type requires matching the technology to the operational demands.

- If your primary focus is reliability in dirty environments: A PTFE liner is the superior choice, as it does not attract abrasive contaminants like grease does.

- If your primary focus is zero-maintenance operation: The self-lubricating nature of a PTFE liner is the definitive solution for "fit-and-forget" applications.

- If your primary focus is high-precision and minimal play: PTFE-lined bearings allow for tighter clearances, reducing unwanted movement in linkages and control systems.

- If your primary focus is extreme impact loads or high heat: You must carefully verify that the specifications of the PTFE-lined bearing meet your demands, as a specialized metal-on-metal greasable bearing may be required.

Ultimately, choosing the right bearing is about understanding your environment and prioritizing the performance characteristics that matter most.

Summary Table:

| Aspect | PTFE-Lined Bearing Advantage |

|---|---|

| Maintenance | Zero-maintenance; no re-lubrication needed |

| Contamination | Superior resistance to dirt and dust |

| Precision | Tighter tolerances for minimal play |

| Lifespan | Extended life by preventing metal-on-metal wear |

| Limitations | Finite wear life; specific temperature/load limits |

Need a reliable, self-lubricating PTFE component for your application?

KINTEK specializes in manufacturing high-precision PTFE components, including custom liners, seals, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution that delivers zero-maintenance operation and superior performance in demanding environments.

Contact our experts today to discuss how our PTFE components can enhance your design's reliability and precision.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments