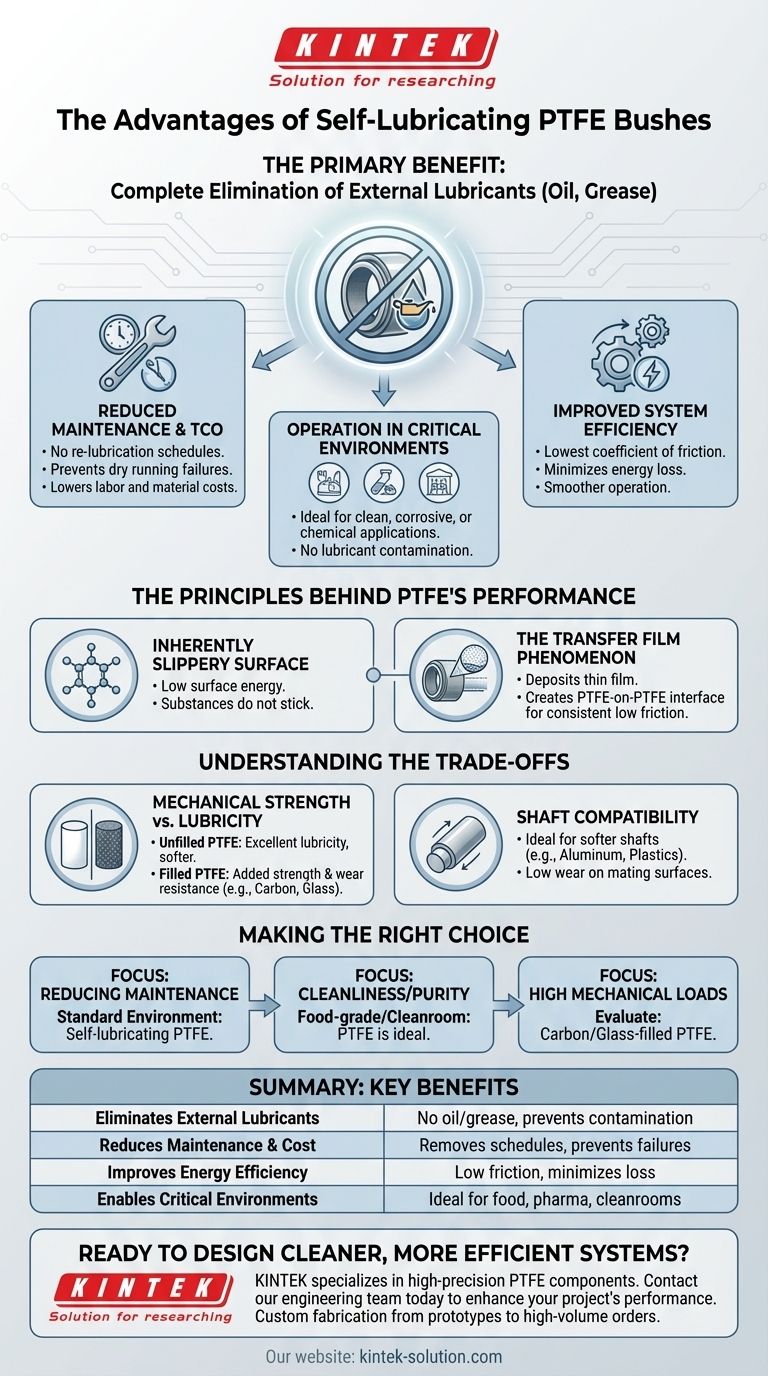

The primary benefit of a PTFE bush's self-lubricating nature is the complete elimination of any need for external lubricants like oil or grease. This inherent property dramatically reduces maintenance requirements, improves energy efficiency by minimizing friction, and enables reliable operation in environments where traditional lubrication is impractical or would act as a contaminant.

The self-lubricating characteristic of PTFE is not just a feature of convenience; it is a fundamental design enabler. It allows for high-performance, maintenance-free motion in applications where other materials would either fail or compromise the integrity of the system.

The Core Advantages of Inherent Lubrication

The decision to use a PTFE bush often centers on its ability to function without external lubrication. This single property creates several cascading benefits for any mechanical system.

Reduced Maintenance and Total Cost of Ownership

Because PTFE bushes require no re-lubrication, they eliminate the labor and material costs associated with regular maintenance schedules.

This also prevents the risk of dry running, a condition where a standard bearing runs out of lubricant, leading to catastrophic failure and system downtime.

Operation in Critical Environments

The absence of oil or grease makes PTFE bushes ideal for applications with strict cleanliness or chemical compatibility requirements.

This includes food processing machinery, pharmaceutical equipment, and cleanroom environments, where any form of liquid lubricant would be a contaminant. Their high chemical resistance also makes them suitable for highly corrosive settings.

Improved System Efficiency

PTFE has one of the lowest coefficients of friction of any solid material.

This low-friction surface minimizes the energy lost to resistance between moving parts. The result is smoother operation and a measurable improvement in overall energy efficiency.

The Principles Behind PTFE's Performance

Understanding why PTFE is self-lubricating helps in appreciating its proper application and limitations. This capability stems directly from its unique molecular structure.

An Inherently Slippery Surface

The chemical composition of Polytetrafluoroethylene (PTFE) creates a material with very low surface energy. This means other substances do not readily stick to it, resulting in its famously "slippery" characteristic.

The Transfer Film Phenomenon

During initial operation, the PTFE bush deposits a microscopic, thin film of its own material onto the mating shaft surface.

Once this transfer film is established, the movement is no longer metal-on-PTFE, but rather PTFE-on-PTFE. This interface is what produces the extremely low friction and consistent, smooth performance over the component's life.

Understanding the Trade-offs

While its self-lubricating nature is a powerful advantage, it is essential to consider the trade-offs inherent to standard PTFE to make an informed engineering decision.

Mechanical Strength vs. Lubricity

Pure, unfilled PTFE is a relatively soft material. It excels in low-friction applications but may deform or wear quickly under high mechanical loads or pressures.

To counteract this, filled PTFE variants are used. Adding fillers like carbon or glass improves mechanical strength, wear resistance, and thermal conductivity, making the bushes suitable for more demanding applications while retaining excellent self-lubricating properties.

Compatibility with Shaft Materials

Because PTFE is a soft material, it is an excellent choice for use with softer shafts, such as those made from aluminum or certain plastics. It is far less likely to cause wear on the mating surface compared to a metallic bearing.

Making the Right Choice for Your Goal

Selecting the right bearing material requires aligning its properties with the primary demands of your application.

- If your primary focus is reducing maintenance in a standard environment: A self-lubricating PTFE bush is an excellent choice to eliminate lubrication schedules and prevent failures from dry running.

- If your primary focus is cleanliness or chemical purity: PTFE is the ideal solution for food-grade, cleanroom, or corrosive applications where external lubricants are forbidden.

- If your primary focus is handling high mechanical loads: You should evaluate a carbon-filled or glass-filled PTFE bush to gain the necessary strength and wear resistance.

Ultimately, leveraging the self-lubricating nature of PTFE allows you to design cleaner, more efficient, and more reliable mechanical systems.

Summary Table:

| Key Benefit | Description |

|---|---|

| Eliminates External Lubricants | No need for oil or grease, preventing contamination. |

| Reduces Maintenance & Cost | Removes lubrication schedules and prevents dry-running failures. |

| Improves Energy Efficiency | Low coefficient of friction minimizes energy loss. |

| Enables Critical Environments | Ideal for food, pharmaceutical, and cleanroom applications. |

Ready to design cleaner, more efficient, and maintenance-free systems?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including self-lubricating bushes, seals, liners, and custom labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the perfect solution for your specific application in the semiconductor, medical, laboratory, or industrial sectors.

Contact our engineering team today to discuss how our PTFE components can enhance your project's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials