At its core, a Teflon PTFE sheet is made from a synthetic fluoropolymer called Polytetrafluorofluoroethylene (PTFE). This material is renowned for its unique and powerful combination of properties, most notably its exceptional non-stick surface, high heat resistance, and extreme chemical inertness.

The true value of PTFE isn't derived from a single characteristic, but from the synergy of its core properties. This creates a uniquely stable and reliable material that performs consistently in extreme environments—from corrosive chemical processing to high-temperature mechanical systems—where most other plastics would quickly fail.

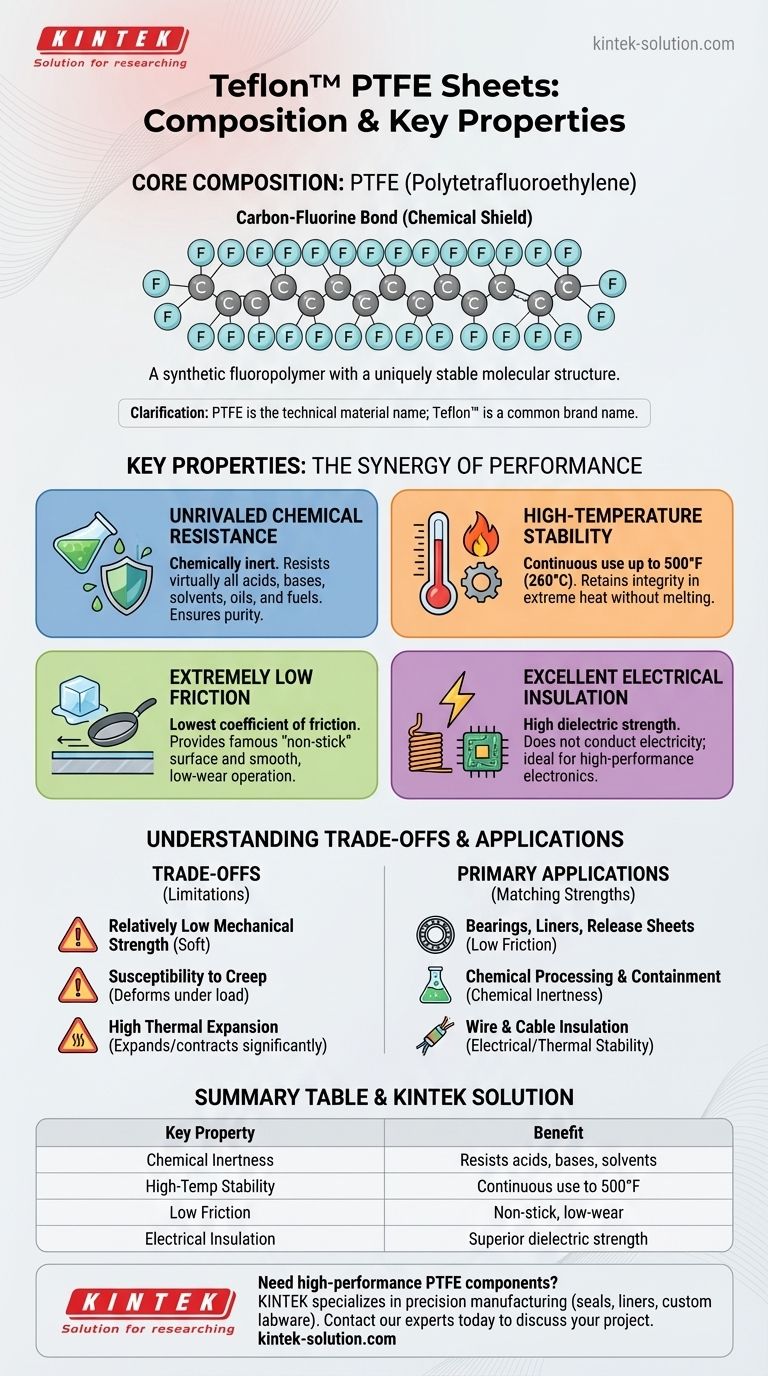

What is Polytetrafluoroethylene (PTFE)?

To understand the properties of these sheets, we must first understand the material itself. PTFE is a high-performance engineering plastic that holds a unique place in material science.

A Synthetic Fluoropolymer

PTFE is composed of a long chain of carbon atoms, where each carbon is completely surrounded and protected by fluorine atoms. This carbon-fluorine bond is one of the strongest in organic chemistry.

This incredibly stable molecular structure is the source of PTFE's most valuable traits. It acts as a chemical shield, making the material nearly impervious to attack.

Clarifying the Name: Teflon vs. PTFE

It is important to distinguish between the material and the brand.

PTFE is the generic, technical name for the polytetrafluoroethylene polymer. Teflon™ is simply the most famous brand name for PTFE, created by the Chemours Company (originally DuPont). While often used interchangeably, PTFE is the correct engineering term for the material itself.

The Core Properties Explained

The molecular structure of PTFE gives rise to a set of highly desirable engineering properties that make it suitable for demanding applications.

Unrivaled Chemical Resistance

Because of its strong carbon-fluorine bonds, PTFE is chemically inert. It offers exceptional resistance to a vast range of substances, including aggressive acids, bases, solvents, oils, and fuels.

This means it will not degrade or react when exposed to even the most corrosive industrial chemicals, ensuring purity and longevity in processing lines and containment systems.

High-Temperature Stability

PTFE sheets can operate continuously at very high temperatures, typically up to 500°F (260°C), without melting or losing their structural integrity.

This makes the material ideal for use in high-temperature seals, gaskets, and insulation where other plastics would warp or decompose. It also performs exceptionally well at extremely low temperatures.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it the famous "non-stick" quality.

In mechanical applications, this property allows for smooth, low-wear operation in components like slide bearings, gears, and liners. For processing, it provides an excellent release surface that prevents materials from sticking.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with a high dielectric strength. It does not conduct electricity, making it a critical material for high-performance wiring, circuit boards, and other electronic components, especially at high frequencies.

Understanding the Trade-offs

No material is perfect. To use PTFE effectively, it's critical to understand its limitations.

Relatively Low Mechanical Strength

Compared to metals or other engineering plastics like nylon, PTFE is a relatively soft material. It is not suitable for high-load structural applications where rigidity and high tensile strength are the primary requirements.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in the design of long-term mechanical components like seals or bearing pads.

High Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This means it will expand and contract more significantly with temperature changes, a factor that engineers must consider when designing parts with tight tolerances.

Making the Right Choice for Your Application

Leveraging PTFE successfully requires matching its unique strengths to your primary goal.

- If your primary focus is non-stick surfaces or low-friction movement: PTFE's exceptionally low coefficient of friction makes it the definitive choice for applications like bearings, liners, and release sheets.

- If your primary focus is performance in harsh chemical environments: PTFE's chemical inertness ensures it will not degrade when exposed to nearly all industrial acids, solvents, and bases.

- If your primary focus is high-temperature electrical applications: Its combination of thermal stability and excellent dielectric properties makes it a superior material for high-performance wire and cable insulation.

By understanding these core principles, you can confidently leverage PTFE's unique strengths in your most demanding engineering challenges.

Summary Table:

| Key Property | Benefit |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents |

| High-Temperature Stability | Continuous use up to 500°F (260°C) |

| Low Coefficient of Friction | Excellent non-stick and low-wear characteristics |

| Excellent Electrical Insulation | Superior dielectric strength for electronics |

Need high-performance PTFE components tailored to your specific requirements?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise in custom fabrication ensures you get parts that leverage PTFE's unique properties to solve your most demanding engineering challenges.

Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers