On initial purchase, Teflon encapsulated O-rings are more expensive than standard elastomeric O-rings. However, their true cost-effectiveness is revealed over their lifecycle, where they often provide superior long-term value by outperforming standard seals in demanding environments and proving more practical than solid Teflon rings.

The choice isn't about finding the cheapest seal, but the one with the lowest total cost of ownership for your specific application. Encapsulated O-rings justify their higher initial price by reducing failures, downtime, and replacement costs in chemically aggressive or high-temperature conditions.

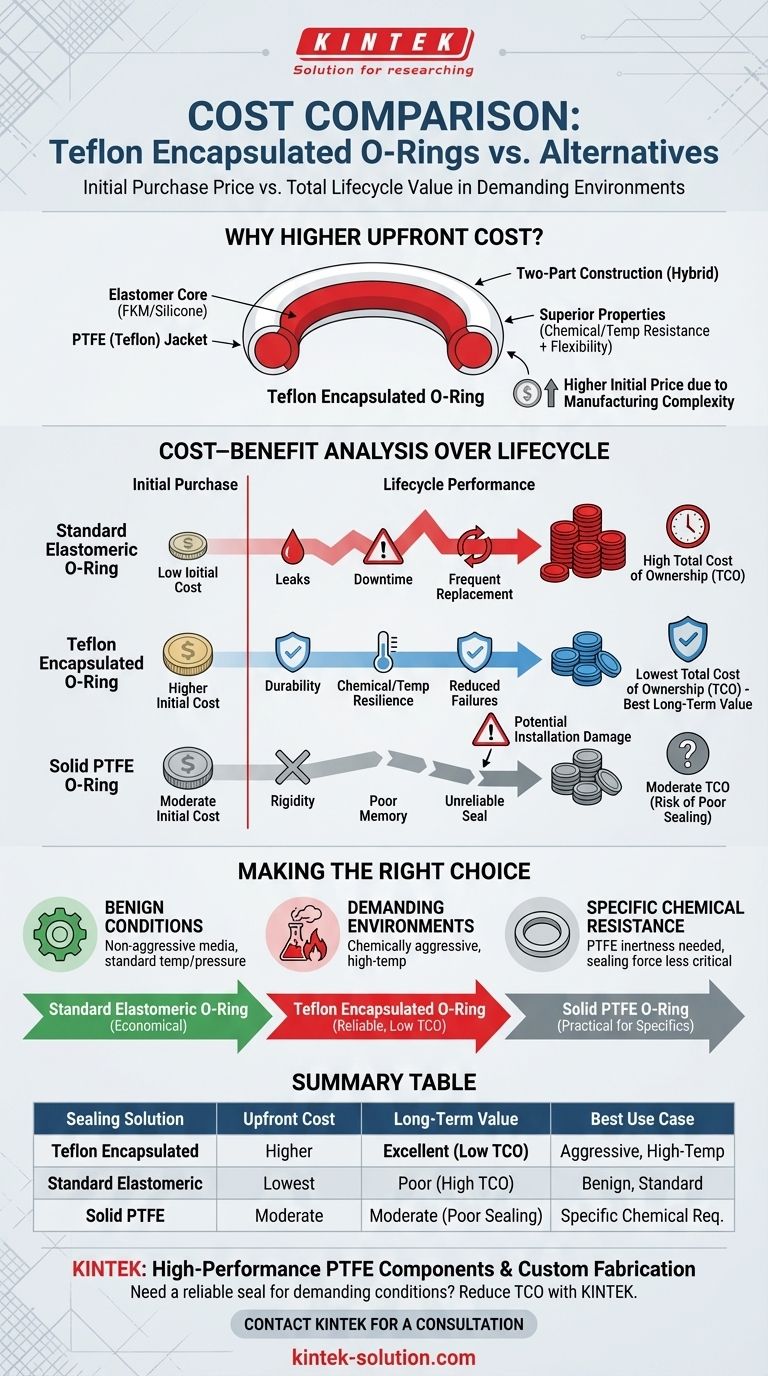

Why Encapsulated O-Rings Have a Higher Upfront Cost

The cost of a seal is directly tied to its materials and manufacturing complexity. Encapsulated O-rings are a hybrid solution, which inherently increases their initial price.

The Two-Part Construction

A Teflon encapsulated O-ring combines an outer PTFE (Teflon) jacket with an inner elastomeric core (like FKM or Silicone). This multi-material design requires a more involved manufacturing process than molding a simple, single-material elastomeric ring.

Superior Material Properties

The PTFE jacket provides elite chemical and temperature resistance, while the elastomer core provides the flexibility and resilience needed for a reliable seal. This combination of properties makes them suitable for highly demanding applications where standard seals would quickly fail.

The Cost-Benefit Analysis vs. Alternatives

The value of an encapsulated O-ring becomes clear when you compare its total lifecycle cost against other common sealing solutions.

Versus Standard Elastomeric O-Rings

In benign applications, a standard elastomer ring is the most cost-effective choice. However, when exposed to harsh chemicals or extreme temperatures, these seals degrade quickly, leading to leaks, costly downtime, and frequent replacement cycles. The encapsulated ring's durability in these environments prevents such failures, saving significant money over time.

Versus Solid PTFE (Teflon) O-Rings

A solid PTFE ring offers the same exceptional chemical resistance as an encapsulated one. The critical difference is its lack of elasticity. Solid PTFE is rigid, has poor "memory," and can be difficult to install, often resulting in an unreliable seal. The encapsulated O-ring provides the chemical inertness of Teflon plus the reliable sealing force of an elastomer, making it a more practical and effective solution.

Understanding the Trade-offs

While highly effective, an encapsulated O-ring is not the default solution for every problem. Understanding its limitations is key to making a sound engineering decision.

When to Choose a Simpler Seal

For applications with non-aggressive media, standard temperatures, and moderate pressures, the advanced properties of an encapsulated O-ring are unnecessary. In these cases, a standard elastomeric ring provides a perfectly reliable seal at a much lower initial cost.

Potential for Installation Damage

The thin PTFE jacket that provides the chemical protection is the ring's primary point of vulnerability. It can be scratched or damaged during installation over sharp threads or in rough glands, compromising the seal. Careful installation is critical to ensure performance.

Making the Right Choice for Your Application

Selecting the correct seal requires a clear understanding of your operational demands and budget.

- If your primary focus is minimizing upfront cost for a non-demanding application: A standard elastomeric O-ring is the most economical and effective choice.

- If your primary focus is reliability in chemically aggressive or high-temperature environments: The long-term durability of a Teflon encapsulated O-ring will prevent costly failures and reduce total ownership cost.

- If your primary focus is combining the chemical inertness of PTFE with a reliable, elastic seal: A Teflon encapsulated O-ring is superior to a rigid, solid PTFE ring.

Choosing the right seal is a strategic decision that directly impacts operational reliability and long-term costs.

Summary Table:

| Sealing Solution | Upfront Cost | Long-Term Value | Best Use Case |

|---|---|---|---|

| Teflon Encapsulated O-Ring | Higher | Excellent (Low TCO) | Chemically aggressive, high-temperature environments |

| Standard Elastomeric O-Ring | Lowest | Poor (High TCO) | Benign, standard temperature/pressure applications |

| Solid PTFE O-Ring | Moderate | Moderate (Poor sealing reliability) | Applications requiring PTFE's chemical resistance but where sealing force is less critical |

Need a reliable seal for demanding conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision Teflon encapsulated O-rings. Our seals are engineered to provide long-lasting reliability in the most challenging semiconductor, medical, laboratory, and industrial applications, reducing your total cost of ownership by minimizing downtime and replacement costs.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today for a consultation and let our experts help you select the most cost-effective sealing solution for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support