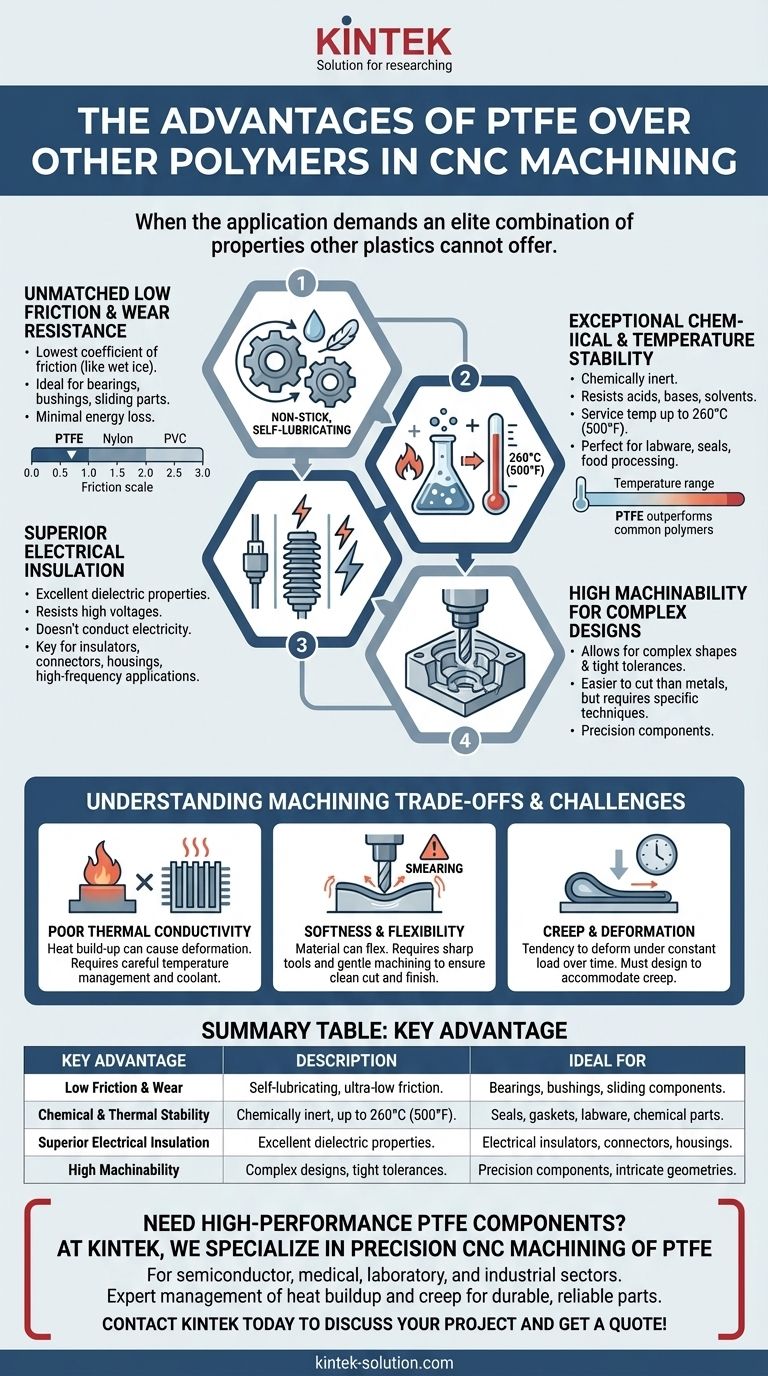

In CNC machining, PTFE is the superior polymer choice when the application demands an elite combination of properties that other plastics cannot simultaneously offer. Its primary advantages over materials like Nylon or PVC are an extremely low coefficient of friction, exceptional resistance to chemicals and high temperatures, and superior electrical insulation. These traits make it the definitive material for high-performance parts in demanding environments.

While many polymers are machinable, PTFE stands out not just for its individual strengths, but for their powerful combination. It is the go-to material when a component must simultaneously resist harsh chemicals, withstand high heat, insulate electricity, and provide a near-frictionless surface.

The Core Properties Defining PTFE's Advantage

The decision to use PTFE often comes down to performance requirements that other polymers simply cannot meet. Its unique molecular structure gives it a set of characteristics that translate directly into durability and reliability in specialized applications.

Unmatched Low Friction and Wear Resistance

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This non-stick, self-lubricating property is its most famous attribute.

This results in components that move smoothly against each other with minimal energy loss or heat generation. It makes PTFE an ideal choice for parts like bearings, bushings, and sliding components that require long life with little to no maintenance.

Exceptional Chemical and Temperature Stability

PTFE is almost completely chemically inert, meaning it will not react with the vast majority of industrial chemicals, acids, and bases. This makes it essential for components used in food processing equipment and laboratory instrumentation.

Furthermore, it maintains its structural integrity across a wide temperature range, with a high melting point of 327°C (621°F) and service temperatures up to 260°C (500°F). This thermal stability ensures reliability in high-temperature environments where other plastics would fail.

Superior Electrical Insulation

PTFE possesses excellent dielectric properties, meaning it is a highly effective electrical insulator. It resists high voltages and does not conduct electricity.

This makes it the material of choice for electrical housings, insulators, and connectors, especially in high-frequency applications where signal integrity is critical.

High Machinability for Complex Designs

Despite its unique properties, PTFE is relatively easy to machine. It allows for the creation of complex shapes and the achievement of very tight tolerances, which is crucial for precision components.

Its softness allows cutting tools to move through it with less force, though this same property introduces specific challenges that require careful management.

Understanding the Machining Trade-offs

While PTFE's properties make it highly desirable, they also present unique challenges during the CNC machining process. Understanding these trade-offs is critical to achieving a successful outcome.

Managing Poor Thermal Conductivity

PTFE does not dissipate heat well. During aggressive machining, heat can build up quickly in the material, causing it to soften, deform, or even melt.

This necessitates careful temperature management, often through the use of sharp tools, appropriate feed rates, and sometimes coolants to prevent dimensional inaccuracies.

Accounting for Softness and Flexibility

The inherent softness that makes PTFE easy to cut can also be a liability. The material can flex away from the cutting tool, and its non-stick surface can lead to "smearing" rather than clean cutting if parameters are incorrect.

Machinists must use very sharp tools and gentle machining strategies to avoid deforming the part and ensure a clean surface finish.

The Challenge of Creep and Deformation

PTFE has a high creep rate, meaning it has a tendency to slowly deform over time when subjected to a constant load, especially at elevated temperatures.

This must be considered during the design phase. Parts that will be under constant compressive stress, like seals or gaskets, need to be designed to accommodate this long-term deformation.

Making the Right Choice for Your Application

Selecting PTFE is a decision driven by non-negotiable performance needs. Use this framework to determine if its advantages align with your project's goals.

- If your primary focus is smooth, low-wear movement: PTFE is the ideal choice for creating self-lubricating bearings, bushings, and sliding plates.

- If your primary focus is survival in harsh environments: Choose PTFE for seals, gaskets, and components exposed to aggressive chemicals or high temperatures.

- If your primary focus is electrical performance: PTFE is the superior option for high-voltage or high-frequency insulators and connectors where signal loss is unacceptable.

- If your primary focus is biocompatibility and purity: PTFE's inertness makes it a safe and reliable choice for medical devices and food-grade processing equipment.

Ultimately, choosing PTFE is an investment in unparalleled performance where standard plastics would fail.

Summary Table:

| Key Advantage | Description | Ideal For |

|---|---|---|

| Low Friction & Wear | Self-lubricating with one of the lowest coefficients of friction. | Bearings, bushings, sliding components. |

| Chemical & Thermal Stability | Chemically inert, with service temperatures up to 260°C (500°F). | Seals, gaskets, labware, chemical processing parts. |

| Superior Electrical Insulation | Excellent dielectric properties for high-frequency/high-voltage use. | Electrical insulators, connectors, housings. |

| High Machinability | Allows for complex designs and tight tolerances. | Precision components with intricate geometries. |

Need high-performance PTFE components that other plastics can't match?

At KINTEK, we specialize in precision CNC machining of PTFE for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We expertly manage the unique challenges of machining PTFE—like heat buildup and material creep—to deliver durable, reliable parts that meet your exact specifications.

Whether you require prototypes or high-volume production, our custom fabrication ensures your components deliver the unparalleled chemical resistance, thermal stability, and low friction that only PTFE can provide.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs