In short, glass-filled PTFE rods are used in aerospace because the glass filler adds critical strength, stiffness, and wear resistance to standard PTFE. This enhancement allows the material to maintain its shape and function reliably under the high loads and extreme temperature variations found in critical aircraft components like control system bearings and high-performance seals.

While standard PTFE offers exceptional low-friction and chemical resistance, it is often too soft for demanding structural roles. The addition of glass fibers provides the necessary mechanical reinforcement, creating a composite material that withstands the immense stresses of aerospace applications without sacrificing PTFE's core benefits.

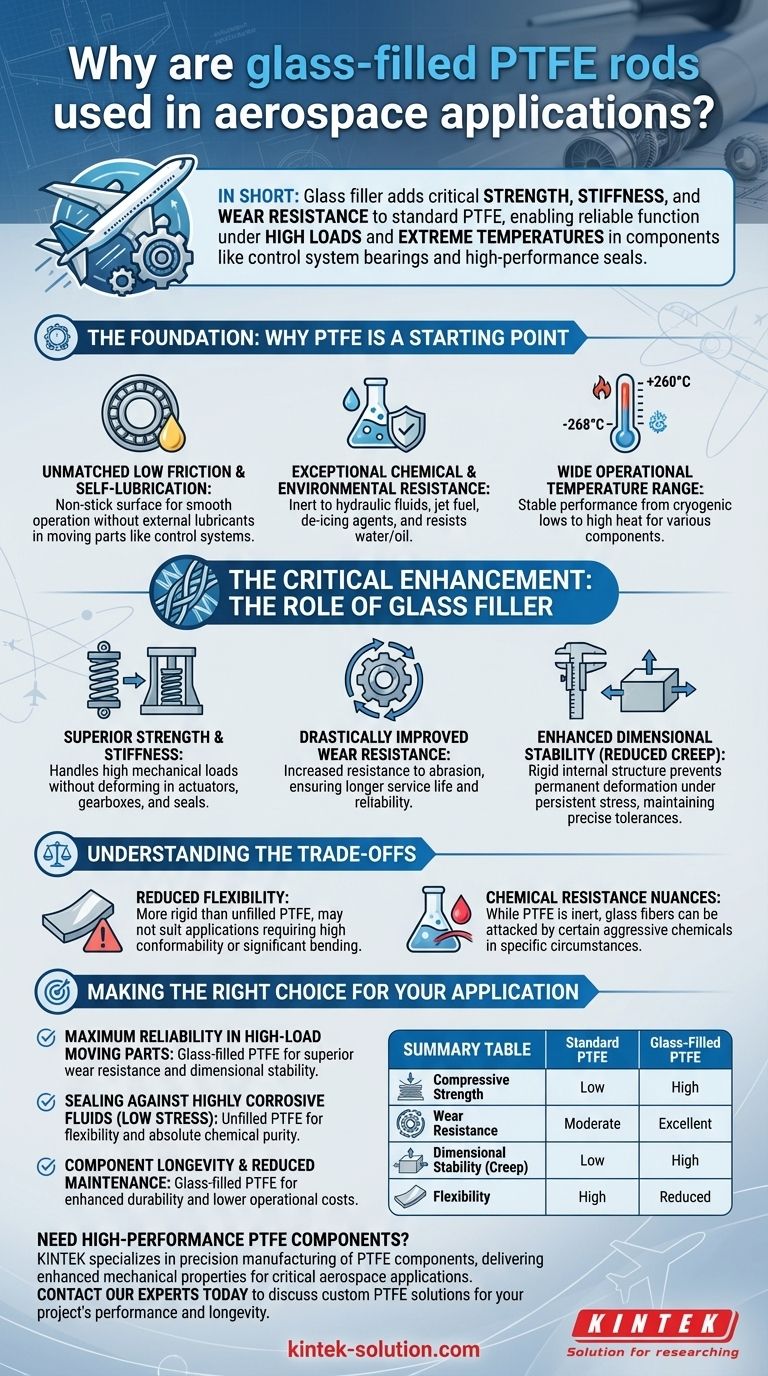

The Foundation: Why PTFE is a Starting Point

Before understanding the role of the glass filler, it's essential to recognize the inherent advantages of the base Polytetrafluoroethylene (PTFE) polymer.

Unmatched Low Friction and Self-Lubrication

PTFE possesses one of the lowest coefficients of friction of any solid material. This creates a naturally non-stick, self-lubricating surface.

In aerospace, this property is vital for moving parts like bearings or sliding elements in control systems, ensuring smooth operation without the need for external lubricants that could fail at extreme altitudes or temperatures.

Exceptional Chemical and Environmental Resistance

PTFE is almost entirely chemically inert. It resists degradation from aggressive hydraulic fluids, jet fuel, de-icing agents, and other corrosive substances.

Its non-wetting properties also mean it resists water and oil, which helps components stay clean and function reliably over long periods.

Wide Operational Temperature Range

The material remains stable and functional across an incredibly broad temperature spectrum, from cryogenic lows (-268°C) to high-heat environments (+260°C). This makes it suitable for components throughout an aircraft, from landing gear to engine systems.

The Critical Enhancement: The Role of Glass Filler

Adding glass fibers transforms PTFE from a high-performance polymer into a robust engineering-grade composite. This enhancement directly addresses the mechanical weaknesses of unfilled PTFE.

Superior Strength and Stiffness

The primary benefit of the glass filler is a significant increase in compressive strength and stiffness.

This allows components made from glass-filled PTFE to handle high mechanical loads without deforming, a non-negotiable requirement for actuators, gearboxes, and structural seals.

Drastically Improved Wear Resistance

Glass fibers dramatically increase the material's resistance to wear and abrasion from repeated motion.

For components in aircraft control systems or turbine engines, this translates directly to a longer service life, increased reliability, and reduced maintenance downtime.

Enhanced Dimensional Stability (Reduced Creep)

Perhaps the most crucial enhancement is the reduction of creep. Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

Unfilled PTFE can be prone to creep, but the glass fibers provide a rigid internal structure. This ensures that precision-machined parts like seals and bearings maintain their exact shape and tolerances over thousands of operational hours.

Understanding the Trade-offs

While glass filler provides immense benefits, it's important to understand the compromises involved in its use.

Reduced Flexibility

The added stiffness and strength come at the cost of flexibility. Glass-filled PTFE is more rigid than its unfilled counterpart.

For applications requiring a seal to conform to a highly irregular surface or bend significantly, pure PTFE might be a more suitable choice.

Chemical Resistance Nuances

While the PTFE matrix remains highly inert, certain aggressive chemicals can, in very specific circumstances, attack the glass fibers themselves.

For the vast majority of aerospace applications, this is not a concern, but it is a factor that engineers must consider when dealing with exceptionally caustic or unusual chemical environments.

Making the Right Choice for Your Application

Selecting the correct material is about aligning its properties with the primary demands of the component.

- If your primary focus is maximum reliability in high-load moving parts: Glass-filled PTFE is the definitive choice for its superior wear resistance and dimensional stability.

- If your primary focus is sealing against highly corrosive fluids in a low-stress application: The flexibility and absolute chemical purity of unfilled PTFE may be more advantageous.

- If your primary focus is component longevity and reduced maintenance: The enhanced durability of glass-filled PTFE ensures a longer lifespan and less frequent replacement, reducing overall operational costs.

Ultimately, choosing glass-filled PTFE is a strategic decision to build components with the mechanical integrity required to perform flawlessly in an environment where failure is not an option.

Summary Table:

| Property | Standard PTFE | Glass-Filled PTFE |

|---|---|---|

| Compressive Strength | Low | High |

| Wear Resistance | Moderate | Excellent |

| Dimensional Stability (Creep) | Low | High |

| Flexibility | High | Reduced |

Need high-performance PTFE components that meet the rigorous demands of the aerospace industry?

KINTEK specializes in the precision manufacturing of PTFE components, including custom glass-filled rods, seals, liners, and labware. We deliver the enhanced mechanical properties and reliability your critical applications require, from prototypes to high-volume production.

Contact our experts today to discuss how our custom PTFE solutions can enhance your project's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability