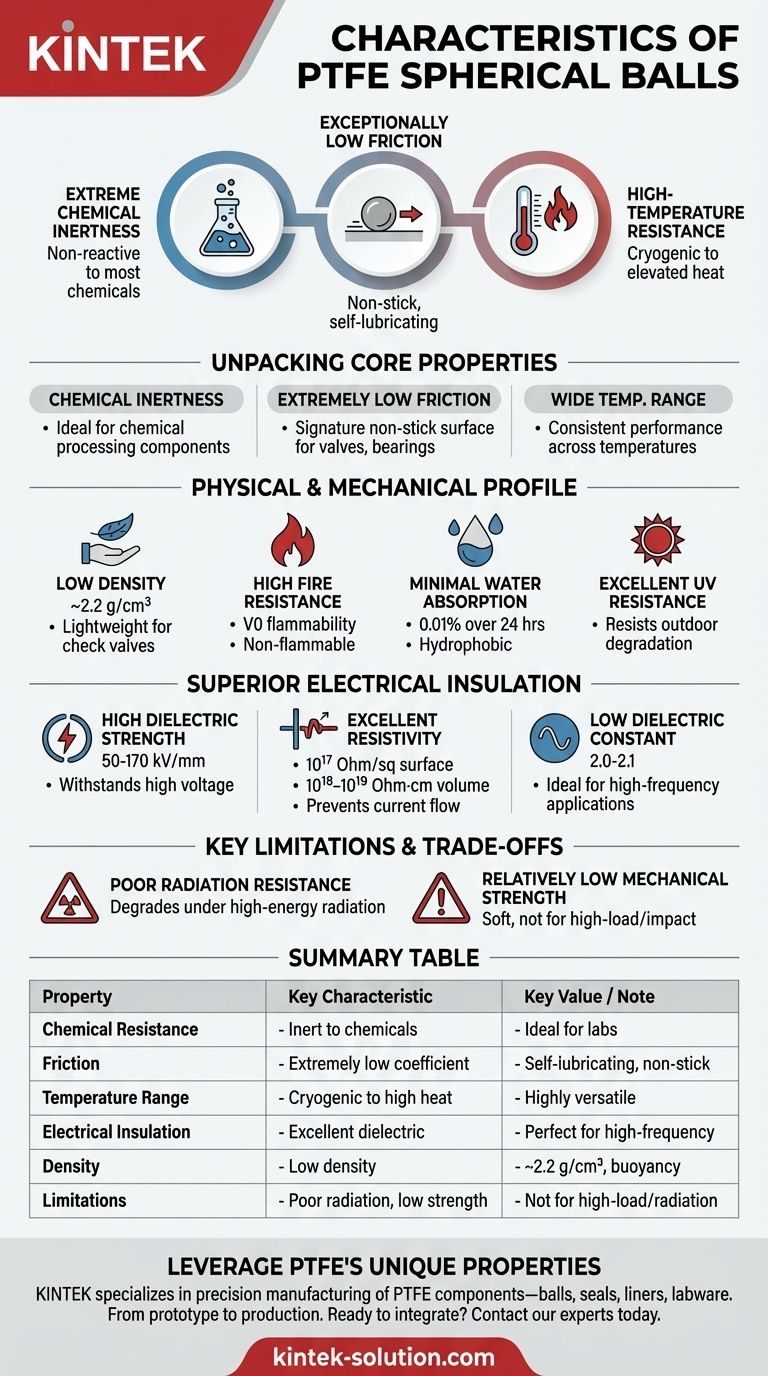

At their core, PTFE spherical balls are defined by their extreme chemical inertness, exceptionally low coefficient of friction, and high-temperature resistance. These characteristics stem directly from the strong carbon-fluorine bonds of their polytetrafluoroethylene composition. This unique molecular structure makes them highly stable and non-reactive, suitable for a wide range of demanding applications.

The defining characteristic of PTFE is its rare combination of properties: it is simultaneously resistant to nearly all chemicals, an excellent electrical insulator, and one of the lowest-friction solid materials known. Understanding this profile is key to leveraging its strengths while being mindful of its limitations.

Unpacking the Core Properties of PTFE

The value of PTFE balls originates from three primary characteristics that make them suitable for environments where other materials would quickly fail.

Exceptional Chemical Inertness

The molecular structure of PTFE, composed of strong carbon-fluorine bonds, makes it non-reactive to almost all chemicals and solvents. This makes it an ideal choice for components in chemical processing equipment.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This results in its signature non-stick, self-lubricating surface, which is crucial for applications like non-return valves and low-load bearings.

Wide Operational Temperature Range

These balls perform consistently across a broad spectrum of temperatures. They maintain their properties in both cryogenic conditions and elevated heat, making them highly versatile.

The Physical and Mechanical Profile

Beyond the core chemical and thermal traits, the physical makeup of PTFE balls contributes directly to their most common applications.

Low Density

With a density of approximately 2.2 g/cm³, PTFE balls are relatively lightweight. This property is particularly useful in check valves and flow meters where buoyancy and quick response are necessary.

High Fire Resistance

PTFE is inherently non-flammable, boasting a V0 flammability rating and a limiting oxygen index (LOI) of 95%. This means it will not sustain a flame in normal atmospheric conditions.

Minimal Water Absorption

The material is highly hydrophobic, with a water absorption rate of just 0.01% over 24 hours. This ensures dimensional stability and consistent performance in humid or submerged environments.

Excellent UV Resistance

PTFE shows excellent resistance to degradation from ultraviolet (UV) radiation. This allows it to be used in outdoor applications or where exposure to UV light is expected without becoming brittle.

Superior Electrical Insulation Capabilities

PTFE is one of the best electrical insulating materials available, making it a critical component in many electronic and electrical applications.

High Dielectric Strength

It possesses a high dielectric strength, ranging from 50-170 kV/mm. This means it can withstand a very high voltage over a short distance before electrical breakdown occurs.

Excellent Resistivity

The material exhibits incredibly high surface and volume resistivity (10¹⁷ Ohm/sq and 10¹⁸-10¹⁹ Ohm·cm, respectively). This prevents the flow of electrical current, making it a perfect insulator.

Low Dielectric Constant

With a low dielectric constant of 2.0-2.1, PTFE stores very little electrical energy when subjected to an electric field. This, combined with a low dissipation factor, makes it ideal for high-frequency applications where signal integrity is paramount.

Key Limitations and Trade-offs

No material is perfect, and a trusted advisor must highlight the areas where PTFE is not the optimal choice. Its unique strengths are accompanied by specific weaknesses.

Poor Radiation Resistance

PTFE is highly susceptible to damage from high-energy radiation, such as gamma rays or electron beams. This radiation breaks the carbon-fluorine bonds, causing the material to degrade and lose its structural integrity.

Relatively Low Mechanical Strength

While it has good abrasion resistance for a polymer, PTFE is a soft material. It is not suitable for high-load or high-impact applications where mechanical strength and rigidity are the primary requirements.

Is PTFE the Right Choice for Your Application?

To determine if PTFE balls are the correct solution, align their distinct characteristics with your primary goal.

- If your primary focus is chemical processing or laboratory use: PTFE is an ideal choice due to its near-universal chemical inertness and ability to prevent "bumping" during boiling.

- If your primary focus is low-friction mechanical systems: Its self-lubricating, non-stick surface makes it perfect for non-return valves, vacuum pumps, and low-load bearings.

- If your primary focus is high-frequency electrical insulation: Its low dielectric constant and high resistivity make it one of the best materials available for insulating sensitive components.

- If your primary focus is use in a high-radiation environment: You must select a different material, as PTFE will degrade rapidly under these conditions.

Choosing the right material begins with a clear understanding of its fundamental properties, both its advantages and its inherent compromises.

Summary Table:

| Property | Key Characteristic | Key Value / Note |

|---|---|---|

| Chemical Resistance | Inert to nearly all chemicals | Ideal for labs & chemical processing |

| Friction | Extremely low coefficient of friction | Self-lubricating, non-stick surface |

| Temperature Range | Performs from cryogenic to high heat | Highly versatile |

| Electrical Insulation | Excellent dielectric strength & resistivity | Perfect for high-frequency applications |

| Density | Low density | ~2.2 g/cm³, useful for buoyancy |

| Limitations | Poor radiation resistance, low mechanical strength | Not for high-load/radiation environments |

Leverage PTFE's Unique Properties for Your Application

PTFE spherical balls are engineered to solve complex challenges in semiconductor, medical, laboratory, and industrial settings. Their combination of chemical inertness, low friction, and electrical insulation is unmatched.

KINTEK specializes in the precision manufacturing of PTFE components—including custom spherical balls, seals, liners, and labware. We work with you from prototype to high-volume production to ensure your components meet exact specifications for performance and durability.

Ready to integrate high-performance PTFE solutions into your design? Contact our experts today to discuss your project requirements and receive a quote.

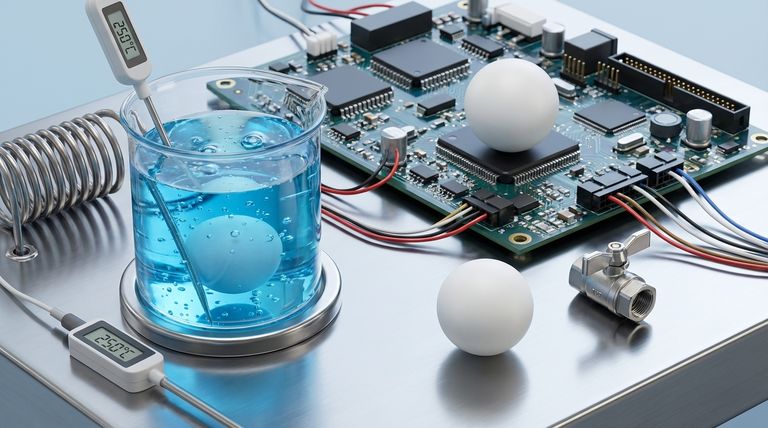

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments