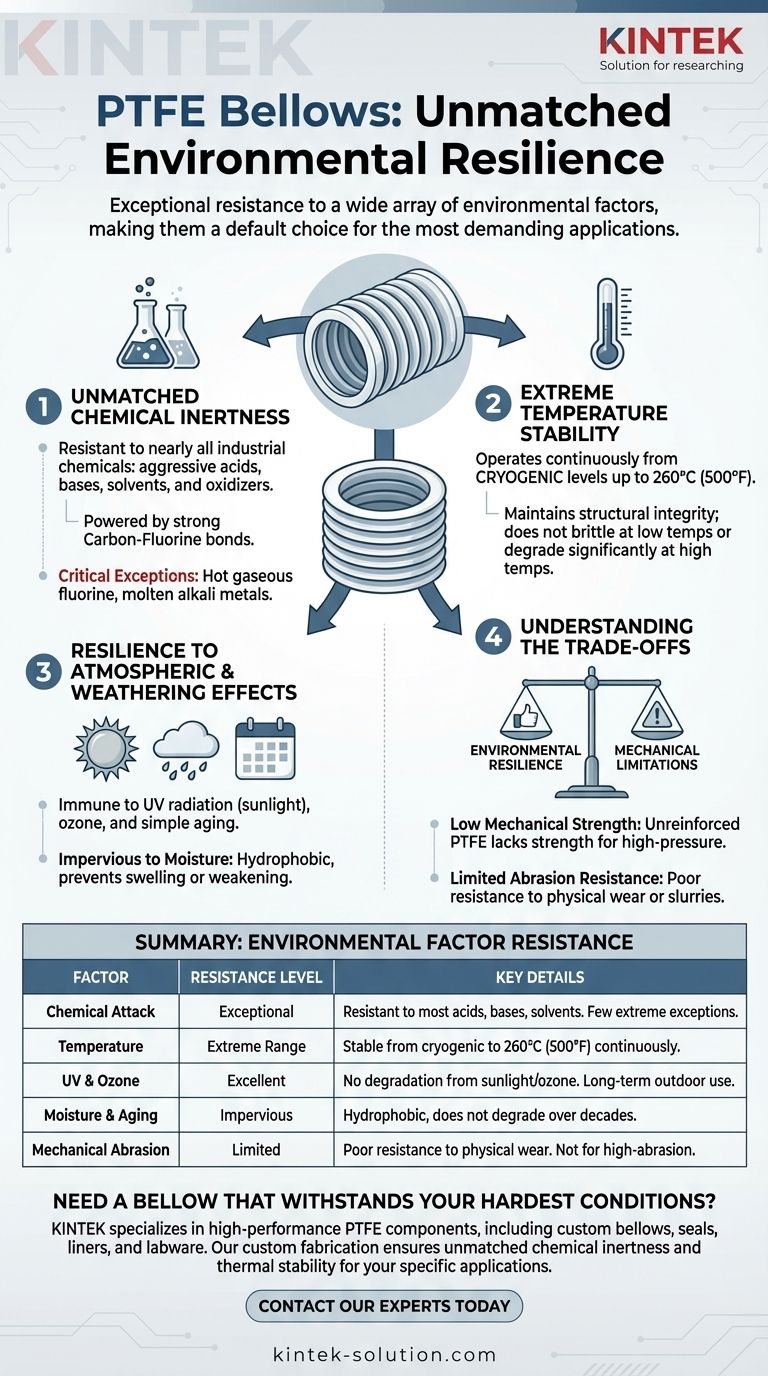

In short, PTFE bellows offer exceptional resistance to a wide array of environmental factors, making them a default choice for the most demanding applications. They are virtually immune to chemical attack, stable across extreme temperature ranges from cryogenic to 260°C (500°F), and do not degrade from exposure to UV radiation, ozone, moisture, or simple aging.

The core takeaway is that PTFE's resilience is almost purely chemical and thermal. Its primary vulnerabilities are not environmental but mechanical, specifically a lack of strength for high-pressure or high-abrasion applications.

Unmatched Chemical Inertness

The defining characteristic of Polytetrafluoroethylene (PTFE) is its extreme chemical resistance, which makes it invaluable in corrosive environments.

The Power of Carbon-Fluorine Bonds

PTFE's stability comes from the powerful bonds between its carbon and fluorine atoms. These bonds are exceptionally strong and shield the carbon backbone of the molecule from chemical attack.

This molecular structure makes PTFE one of the most non-reactive materials known. It does not dissolve in any known solvent at room temperature.

Resistance Across a Wide Spectrum

Because of its inert nature, PTFE is resistant to nearly all industrial chemicals, including aggressive acids, bases, solvents, and oxidizers.

This is why PTFE bellows are standard in chemical processing, pharmaceutical manufacturing, and coating technology where contact with harsh substances is constant.

Critical Chemical Exceptions

While nearly inert, PTFE is not completely invincible. A very small number of highly reactive chemicals can attack it under specific conditions.

These include hot gaseous fluorine, chlorine trifluoride, oxygen difluoride, and molten alkali metals like sodium. For virtually all other applications, its chemical resistance is considered universal.

Extreme Temperature Stability

PTFE bellows maintain their integrity and function across a remarkably wide operational temperature range, outperforming most elastomers and plastics.

From Cryogenic Cold to High Heat

PTFE is effective in applications ranging from cryogenic levels up to a continuous service temperature of 260°C (500°F).

Unlike many materials, it does not become brittle or crack at low temperatures, nor does it soften or degrade significantly at high temperatures within its specified range.

Maintaining Structural Integrity

This stability means a PTFE bellow will not compromise the system it's designed to protect, whether it's handling super-cooled liquids or hot fluids and gases.

Resilience to Atmospheric and Weathering Effects

Beyond chemicals and temperature, PTFE excels in resisting common environmental factors that degrade lesser materials over time.

Immunity to UV, Ozone, and Aging

PTFE suffers no degradation from exposure to sunlight (UV radiation), ozone, or the simple effects of aging. Its properties remain stable over decades of service.

This makes it an excellent choice for long-term outdoor installations or equipment where component longevity is critical and replacement is difficult.

Impervious to Moisture

The material is hydrophobic, meaning it repels water. It will not absorb moisture from the air or from direct contact, preventing swelling, weakening, or changes in dimension.

Understanding the Trade-offs: Mechanical vs. Environmental Strength

To choose PTFE correctly, you must weigh its profound environmental resilience against its distinct mechanical limitations.

Low Mechanical Strength and Pressure Limits

PTFE is a relatively soft material. Consequently, unreinforced PTFE bellows lack the mechanical strength for high-pressure applications. They are best suited for isolating vibration, absorbing movement, and connecting misaligned components in low-pressure systems.

Limited Abrasion Resistance

While resistant to chemical corrosion, PTFE has poor resistance to physical abrasion. If the application involves slurries with hard particles or significant rubbing against other surfaces, the material can wear away quickly.

Cost Considerations

PTFE is a premium performance material, and its cost is typically higher than that of alternatives like rubber or some composite bellows. The initial investment must be justified by the need for its unique properties.

Making the Right Choice for Your Application

Selecting the correct bellow material requires matching its profile to your primary operational challenge.

- If your primary focus is handling aggressive chemicals or wide temperature swings: PTFE is the definitive choice, offering reliability where most other materials would fail.

- If your primary focus is managing high system pressure or physical abrasion: You must carefully verify that PTFE's mechanical limits are acceptable, or else consider a reinforced rubber or metal bellow instead.

- If your primary focus is a general-purpose outdoor application with minimal chemical risk: Evaluate if the higher cost of PTFE is necessary, as materials like EPDM rubber also provide excellent UV and ozone resistance for a lower price.

By understanding both its profound environmental resilience and its distinct mechanical limitations, you can confidently specify PTFE bellows for the applications where they deliver unparalleled performance and value.

Summary Table:

| Environmental Factor | PTFE Bellow Resistance Level | Key Details |

|---|---|---|

| Chemical Attack | Exceptional | Resistant to nearly all acids, bases, solvents, and oxidizers. Vulnerable only to a few extreme fluorinating agents. |

| Temperature | Extreme Range | Stable from cryogenic temperatures up to 260°C (500°F) continuously. |

| UV Radiation & Ozone | Excellent | No degradation from sunlight or ozone exposure, ensuring long-term outdoor use. |

| Moisture & Aging | Impervious | Hydrophobic and does not degrade over time, maintaining properties for decades. |

| Mechanical Abrasion | Limited | Poor resistance to physical wear; not suitable for high-abrasion applications. |

Need a bellow that withstands your harshest conditions? KINTEK specializes in manufacturing high-performance PTFE components, including custom bellows, seals, liners, and labware. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get components that deliver unmatched chemical inertness and thermal stability for semiconductor, medical, laboratory, and industrial applications.

Let's discuss your specific requirements. Contact our experts today for a solution tailored to your operational challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does the working process affect PTFE Teflon O-rings? It Dictates Sealing Performance & Lifespan

- What advantages do Teflon sheets have over metal sheets? Discover Unmatched Chemical & Non-Stick Properties

- Why is PTFE used in electrical components? Unmatched Insulation for Extreme Environments

- What are the main applications of ePTFE sheets in the medical industry? From Grafts to Guided Regeneration

- What causes a PTFE butterfly valve to stick or become hard to operate? Diagnose and Fix Common Issues

- In which industries are Teflon backup rings commonly used? Prevent Seal Failure in High-Pressure Systems

- What role do Teflon plastic sheets play in food processing? Solve Stickiness & Boost Efficiency

- In what types of medical devices are PTFE liners particularly useful? Enhance Minimally Invasive Procedures with Superior Lubricity