To be clear, the primary advantages of Teflon (PTFE) sheets over metal sheets center on surface properties and chemical stability, not structural strength. Teflon excels where you need exceptional chemical resistance, an extremely low-friction (non-stick) surface, and high-performance electrical or thermal insulation.

The choice between Teflon and metal is rarely about direct replacement. Instead, it's a decision between a material valued for its structural integrity (metal) and a material valued for its unparalleled surface characteristics and inertness (Teflon).

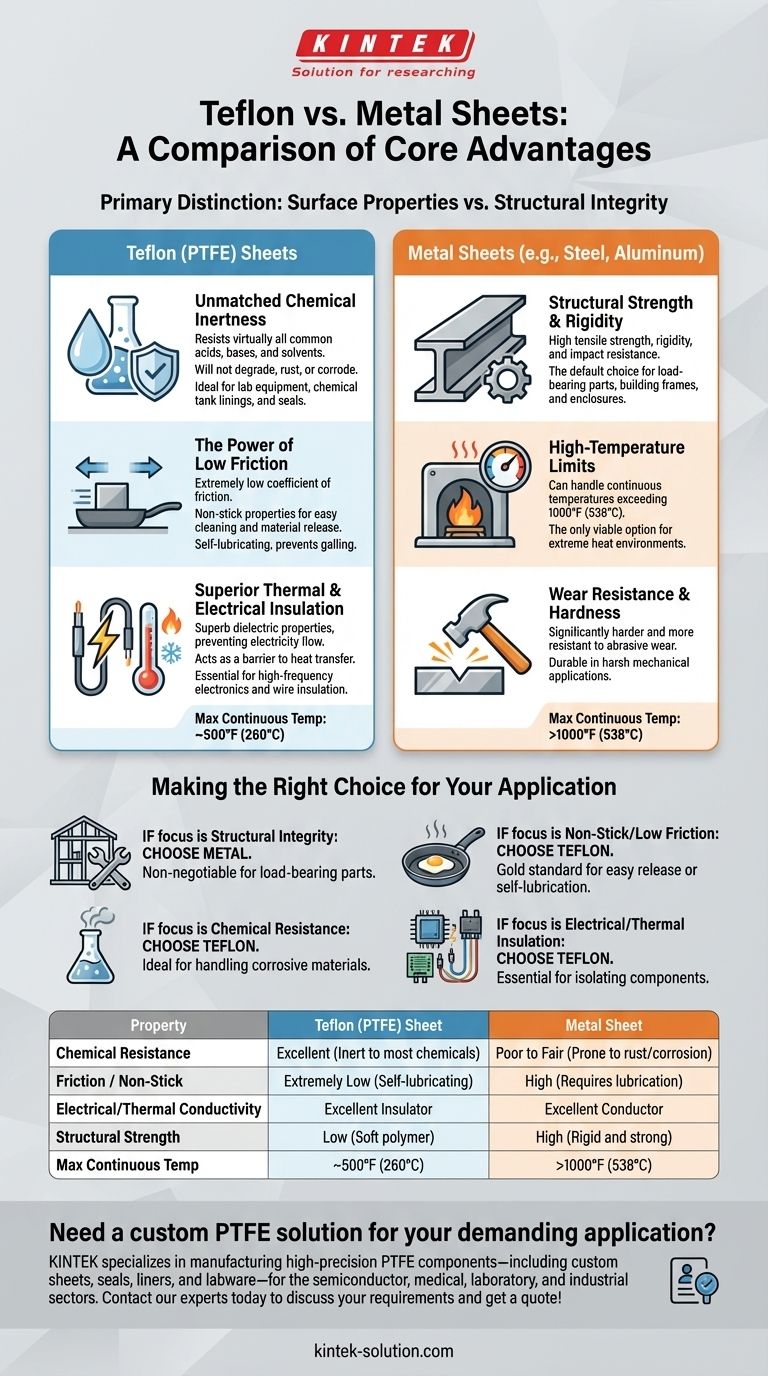

Deconstructing the Core Advantages

While metal forms the backbone of countless applications due to its strength, Teflon offers a unique combination of properties that make it indispensable for specialized roles.

Unmatched Chemical Inertness

Metal sheets, particularly ferrous metals, are susceptible to rust and corrosion when exposed to moisture and a wide range of chemicals.

Teflon is famously chemically inert. It resists virtually all common acids, bases, and solvents, ensuring it will not degrade, rust, or corrode. This makes it a superior choice for lab equipment, chemical tank linings, and seals in harsh environments.

The Power of Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material, which is why it's known for its non-stick properties.

Metal surfaces, by contrast, have much higher friction and can gall or seize without lubrication. Teflon's slipperiness is invaluable for applications like non-stick cooking sheets, self-lubricating bearings, and surfaces that require effortless cleaning or material release, such as in heat presses for crafting.

Superior Thermal and Electrical Insulation

Metals are excellent conductors of heat and electricity. Teflon is the exact opposite—it is a superb electrical and thermal insulator.

This property makes it essential for high-frequency electronics, wire insulation, and any application where you must prevent the flow of electricity. While it has good heat resistance for a polymer, it acts as a barrier to heat transfer rather than a conductor.

Understanding the Trade-offs

Choosing Teflon is not without significant trade-offs. Acknowledging its limitations is critical for proper application.

Structural Strength and Rigidity

This is the most significant differentiator. Metal sheets provide high tensile strength, rigidity, and impact resistance. They are the default choice for building anything that must bear a load.

Teflon is a relatively soft polymer. It has low tensile strength and cannot be used for structural components.

High-Temperature Limits

While Teflon has excellent heat resistance for a plastic, handling continuous temperatures up to 500°F (260°C), this is far below the melting point of most industrial metals like steel or aluminum.

If your application involves temperatures exceeding this threshold, metal is the only viable option.

Wear Resistance and Hardness

Metals are significantly harder and more resistant to abrasive wear than Teflon. While Teflon is durable in non-abrasive sliding applications, it can be easily scratched or worn away by hard, rough materials.

Making the Right Choice for Your Application

Your final decision depends entirely on the primary demand of your project.

- If your primary focus is structural integrity: Choose metal. Its strength, rigidity, and hardness are non-negotiable for building frames, enclosures, or load-bearing parts.

- If your primary focus is a non-stick or low-friction surface: Choose Teflon. It is the gold standard for applications requiring easy release or self-lubrication.

- If your primary focus is chemical resistance: Choose Teflon. Its chemical inertness makes it ideal for handling corrosive materials that would destroy most metals.

- If your primary focus is electrical or thermal insulation: Choose Teflon. Its dielectric properties and low thermal conductivity are essential for isolating components.

Ultimately, these materials solve different problems, which is why Teflon is often used as a critical coating or liner on a structural metal part.

Summary Table:

| Property | Teflon (PTFE) Sheet | Metal Sheet |

|---|---|---|

| Chemical Resistance | Excellent (inert to most acids, bases, solvents) | Poor to Fair (prone to rust/corrosion) |

| Friction / Non-Stick | Extremely Low (self-lubricating) | High (requires lubrication) |

| Electrical/Thermal Conductivity | Excellent Insulator | Excellent Conductor |

| Structural Strength | Low (soft polymer) | High (rigid and strong) |

| Max Continuous Temp | ~500°F (260°C) | >1000°F (538°C) |

Need a custom PTFE solution for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures you get the chemical resistance, non-stick performance, and insulation properties your project demands.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs