In short, the working process is paramount. The manufacturing method fundamentally determines a PTFE O-ring's final density, crystalline structure, and internal stresses. This directly dictates its real-world performance, including its tensile strength (how much it can stretch) and its compressive properties (how well it seals and resists being permanently deformed).

The core issue is that PTFE is not melt-processed like typical plastics. Instead, it is formed through a powder metallurgy-like process of compression and heating (sintering), which means the final O-ring's quality is a direct reflection of how well that process was controlled.

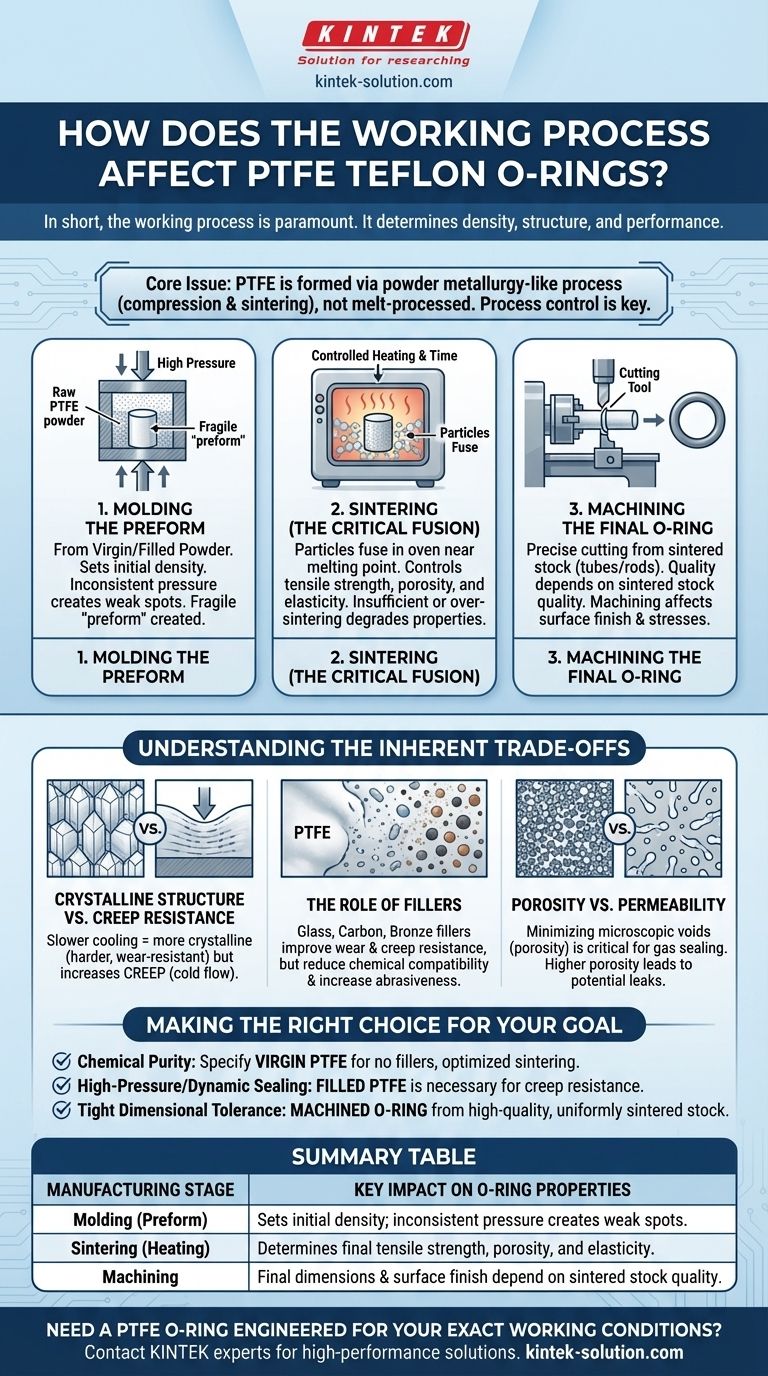

From Powder to Seal: Key Manufacturing Stages

The journey from raw PTFE powder to a finished O-ring is a multi-step process. Each stage imprints critical characteristics onto the final product, and variations in any step will alter performance.

Step 1: Molding the Preform

The process begins with virgin or filled PTFE powder. This powder is compressed in a mold under high pressure to create a solid, but still fragile, shape called a "preform" (often a tube or rod).

The pressure used during this stage sets the initial density of the part. Inconsistent pressure results in a non-uniform component that will have weak spots after the final processing.

Step 2: Sintering (The Critical Fusion)

The preform is then heated in a carefully controlled oven in a process called sintering. The temperature is raised close to, but below, the melting point of PTFE.

This is the most critical step. During sintering, the individual PTFE particles fuse together. The time and temperature of this cycle directly control the O-ring's final tensile strength, porosity, and elasticity.

Insufficient sintering results in a brittle, porous O-ring that will fail prematurely. Over-sintering can degrade the polymer, also compromising its mechanical properties.

Step 3: Machining the Final O-Ring

Most PTFE O-rings are not molded into their final shape. Instead, they are precisely machined from sintered stock shapes like tubes and rods.

The quality of the machined O-ring is therefore entirely dependent on the quality of the stock material it was cut from. A perfectly machined O-ring made from poorly sintered stock will still perform poorly. Furthermore, the machining process itself can introduce surface finishes and stresses that affect sealing ability.

Understanding the Inherent Trade-offs

The choices made during the working process create a series of critical trade-offs that you must understand when specifying a seal.

Crystalline Structure vs. Creep Resistance

The rate at which the PTFE is cooled after sintering determines its crystallinity. A slower cooling rate creates a more crystalline structure, which increases hardness and wear resistance.

However, higher crystallinity can also increase the material's tendency to creep (cold flow). This is PTFE's primary weakness, where the material slowly deforms under constant pressure, leading to seal failure.

The Role of Fillers

To combat creep and improve mechanical properties, fillers are often blended with the PTFE powder before molding. This is a crucial part of the "working process."

Adding fillers like glass, carbon, or bronze dramatically improves wear resistance, reduces creep, and increases compressive strength. The trade-off is often a reduction in chemical compatibility and an increase in abrasiveness against the mating hardware.

Porosity vs. Permeability

Even in a well-sintered part, microscopic voids can exist between the fused particles. This is known as porosity.

A higher-quality sintering process minimizes porosity, creating a denser O-ring. This is critical for gas sealing applications, as higher porosity leads to higher permeability and potential leaks.

Making the Right Choice for Your Goal

When selecting a PTFE O-ring, look beyond the material name and consider the process required to achieve your goal.

- If your primary focus is chemical purity and compatibility: Specify virgin PTFE from a reputable manufacturer to ensure no fillers are present and the sintering process is optimized.

- If your primary focus is high-pressure or dynamic sealing: A filled PTFE is almost always necessary to provide the required creep resistance and durability.

- If your primary focus is tight dimensional tolerance: You will need a machined O-ring, but you must ensure it is made from high-quality, uniformly sintered stock material.

Ultimately, understanding the manufacturing journey of a PTFE O-ring allows you to specify a component based on its performance reality, not just its material name.

Summary Table:

| Manufacturing Stage | Key Impact on O-Ring Properties |

|---|---|

| Molding (Preform) | Sets initial density; inconsistent pressure creates weak spots. |

| Sintering (Heating) | Determines final tensile strength, porosity, and elasticity. |

| Machining | Final dimensions and surface finish depend on quality of sintered stock. |

Need a PTFE O-ring engineered for your exact working conditions?

At KINTEK, we specialize in the precise manufacturing of high-performance PTFE components. Our expertise in controlled compression molding and sintering processes ensures your O-rings have the optimal density, crystalline structure, and mechanical properties for reliable sealing—whether for semiconductor, medical, laboratory, or industrial applications. We offer custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and get a solution that performs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments