At its core, Teflon (PTFE) backup rings are critical components in high-performance sealing systems across a range of demanding industries. They are most commonly used in aerospace, automotive, chemical processing, and food and beverage manufacturing due to their unique combination of chemical inertness, low friction, and resistance to high pressures.

The fundamental role of a Teflon backup ring is not to seal, but to support. It acts as a mechanical support for a primary seal, like an O-ring, preventing it from deforming or "extruding" into the gap between metal components when subjected to high pressure.

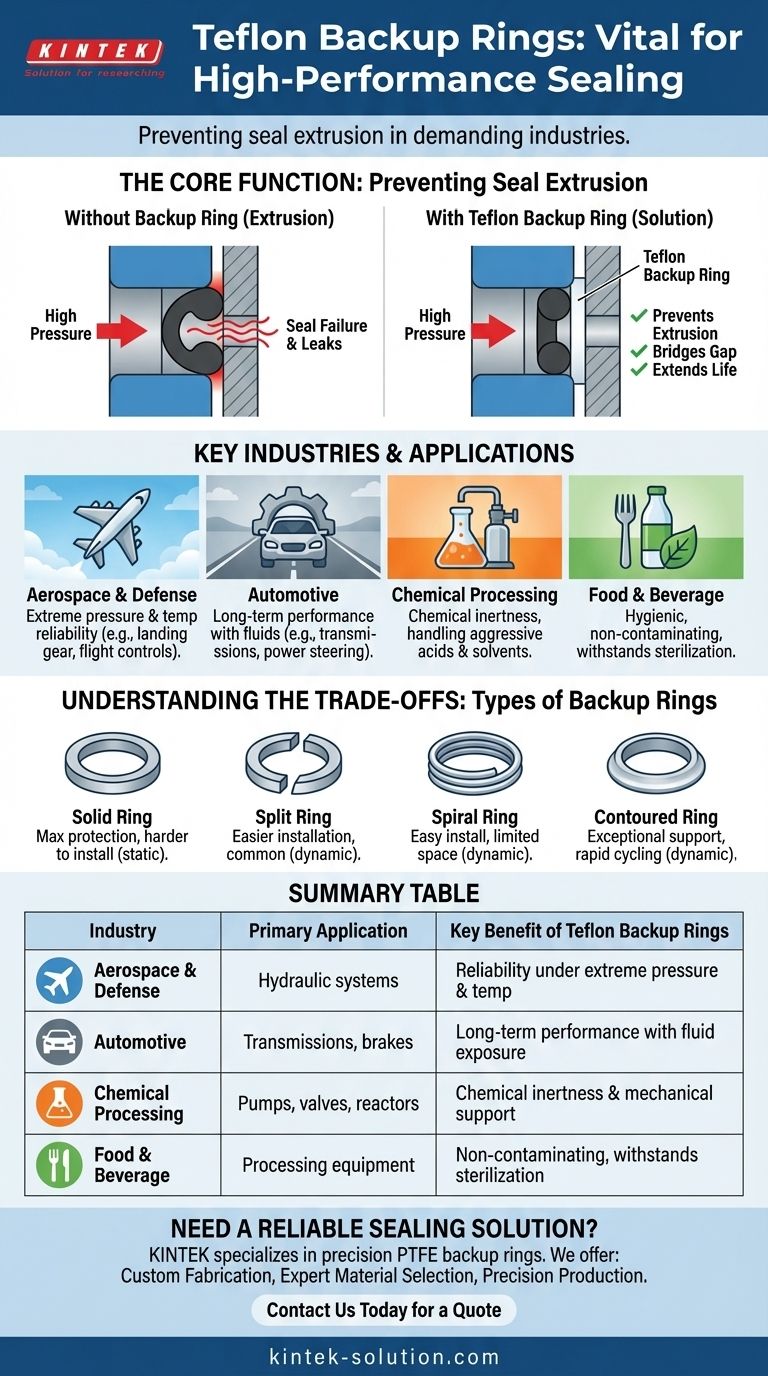

The Core Function: Preventing Seal Extrusion

What is Seal Extrusion?

In any high-pressure hydraulic or pneumatic system, a rubber O-ring is used to create a seal between two components.

Under pressure, the soft O-ring can be forced into the small clearance gap between the moving parts. This physical damage is called extrusion, and it quickly leads to seal failure and system leaks.

How a Backup Ring Solves the Problem

A backup ring, made from a more rigid material like Teflon, is installed on the low-pressure side of the O-ring.

This ring is hard enough to bridge the clearance gap, providing a solid surface that prevents the softer O-ring from being pushed into it. This simple addition dramatically increases the pressure rating and service life of the entire sealing system.

Key Industries and Their Applications

Aerospace and Defense

In aerospace, reliability is non-negotiable. Backup rings are essential in high-pressure hydraulic systems for landing gear, flight controls, and brake systems.

Their use ensures that seals maintain integrity under extreme pressures and temperature fluctuations, preventing catastrophic failures.

Automotive

The automotive industry relies on Teflon backup rings in critical systems like transmissions, power steering, and braking components.

They support the seals that must withstand constant pressure cycles and exposure to various hydraulic fluids and lubricants, ensuring long-term performance and safety.

Chemical Processing

This is where Teflon's legendary chemical inertness is most valuable. In pumps, valves, and reactors handling aggressive acids, bases, and solvents, standard elastomers would quickly degrade.

Teflon backup rings provide the necessary mechanical support without reacting to the harsh chemical environment, ensuring system integrity and preventing hazardous leaks.

Food and Beverage

In food and pharmaceutical manufacturing, equipment must be hygienic and resistant to cleaning chemicals.

Teflon is an ideal material for these applications because it is non-contaminating and can withstand aggressive sterilization and wash-down procedures, making it suitable for use in processing equipment where seal reliability is critical.

Understanding the Trade-offs: Types of Backup Rings

Not all backup rings are the same. The geometry of the ring is chosen based on the specific application, balancing performance with ease of installation.

Solid Rings

A solid, uncut ring offers the maximum protection against extrusion. It provides the most complete coverage of the clearance gap but can be difficult to install, often requiring the seal gland to be designed for it.

Split Rings

A split (or scarf-cut) ring has a single diagonal cut. This design makes installation much easier, as the ring can be slightly expanded to fit over a shaft or into a bore. It is the most common choice for dynamic applications.

Spiral Rings

A spiral-cut ring is coiled like a spring. This configuration is also easy to install and is particularly useful in applications where installation space is limited.

Contoured Rings

Contoured backup rings are machined with a concave face that matches the curvature of the O-ring. This close fit provides exceptional support and stability, especially in dynamic sealing applications with rapid pressure changes.

Making the Right Choice for Your Application

Choosing the correct backup ring is essential for optimizing the performance and lifespan of your sealing system.

- If your primary focus is maximum sealing integrity in a static application: A solid, uncut backup ring provides the best possible extrusion resistance.

- If your primary focus is ease of installation and maintenance in a dynamic system: A split or spiral backup ring is the most practical and common choice.

- If your primary focus is performance in high-pressure, rapid-cycling dynamic systems: A contoured backup ring offers the best support for the O-ring.

Ultimately, incorporating the correct Teflon backup ring transforms a standard O-ring seal into a robust, high-pressure sealing solution.

Summary Table:

| Industry | Primary Application | Key Benefit of Teflon Backup Rings |

|---|---|---|

| Aerospace & Defense | Hydraulic systems (landing gear, flight controls) | Reliability under extreme pressure & temperature |

| Automotive | Transmissions, power steering, brakes | Long-term performance with fluid exposure |

| Chemical Processing | Pumps, valves, reactors handling aggressive chemicals | Chemical inertness and mechanical support |

| Food & Beverage | Processing equipment | Non-contaminating, withstands sterilization |

Need a reliable sealing solution for your high-pressure application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom backup rings for the semiconductor, medical, laboratory, and industrial sectors. We can help you prevent seal extrusion and extend the life of your critical systems.

We offer:

- Custom Fabrication: From prototypes to high-volume orders.

- Expert Material Selection: Ensuring chemical compatibility and performance.

- Precision Production: Guaranteeing a perfect fit and function.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications