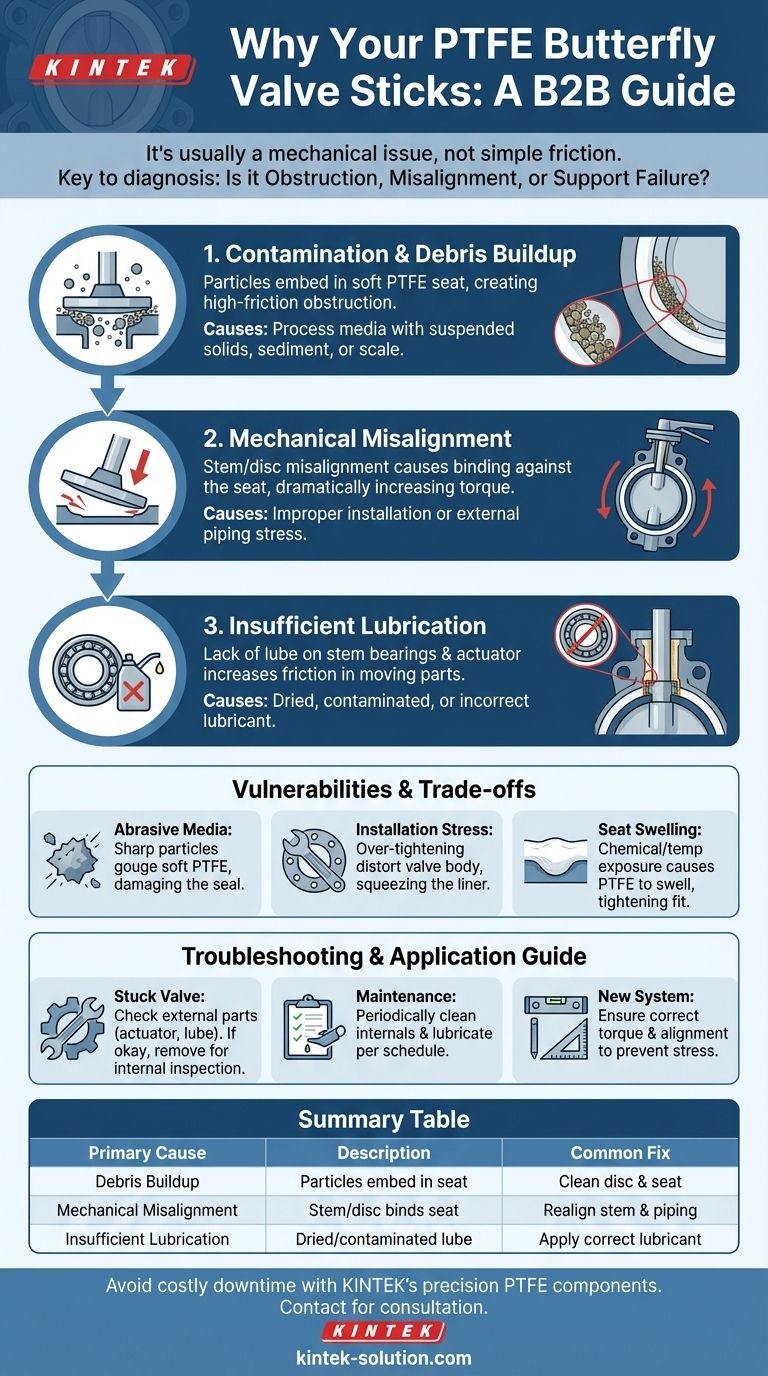

In nearly all cases, a PTFE-seated butterfly valve becomes difficult to operate due to one of three primary mechanical issues. The most common culprits are the accumulation of debris between the disc and the soft seat, the misalignment of the valve stem causing it to bind, or inadequate lubrication of the stem and actuator components.

A sticking butterfly valve is rarely a sign of simple friction; it's a symptom of mechanical interference. The key is to diagnose whether the obstruction is caused by foreign material, component misalignment, or a failure in the valve's support system.

The Primary Causes of Sticking in Detail

Understanding why a valve binds requires looking at the specific points of failure. The soft nature of a PTFE seat makes it particularly susceptible to certain issues that might not affect a hard-seated valve in the same way.

Contamination and Debris Buildup

A butterfly valve's primary seal is the tight contact between the edge of the disc and the soft PTFE liner or seat.

When process media contains suspended solids, sediment, or scale, these particles can become embedded in the soft PTFE material. This creates high-friction spots or a physical obstruction that prevents the disc from rotating smoothly.

Mechanical Misalignment

Proper alignment is critical for the low-torque operation of a butterfly valve. The disc must rotate perfectly centered within the valve body and seat.

Misalignment of the valve stem, often due to improper installation or external stress on the piping, forces the disc to scrape against the seat instead of seating correctly. This binding action dramatically increases the torque required to operate the valve.

Insufficient Lubrication

While the PTFE seat itself is low-friction, the valve's operational torque is also dependent on its external moving parts.

The valve stem bearings and the actuator mechanism require proper lubrication to function. Dried, contaminated, or incorrect lubricant increases friction, making the valve feel stiff or hard to turn, even if the disc and seat are in perfect condition.

Understanding the Trade-offs and Failure Modes

While PTFE offers excellent chemical resistance and a tight seal, its material properties introduce specific vulnerabilities. Recognizing these can help you diagnose problems more accurately.

The Problem of Abrasive Media

PTFE is a relatively soft material. If the process media is abrasive, sharp particles can gouge or embed themselves into the seat.

This not only increases operating torque but can permanently damage the seat, compromising the valve's ability to create a bubble-tight seal.

Installation Stress and Body Distortion

A common and often overlooked cause of binding is improper installation.

Over-tightening the flange bolts can distort the valve body, squeezing the PTFE liner. This distortion reduces the internal clearance, causing the disc to bind against the now-constricted seat throughout its rotation.

Seat Swelling or Deformation

While less common, certain chemical exposures or temperature fluctuations can cause the PTFE material to swell or deform over time.

This change in seat geometry can create a tighter-than-designed fit, leading to a gradual increase in the force needed to operate the valve.

How to Apply This to Your System

A systematic approach can quickly isolate the root cause and guide the correct remedial action.

- If you are troubleshooting a currently stuck valve: First, check the actuator and external lubrication points. If those are fine, the issue is internal and will require removing the valve from the line for inspection, cleaning, and potential realignment.

- If you are performing preventative maintenance: Focus on periodic internal cleaning to remove any sediment buildup and ensure stem bearings are lubricated according to the manufacturer's schedule.

- If you are designing or installing a new system: Ensure flange bolts are tightened to the correct torque specification using a star pattern to prevent body distortion, and confirm the piping is aligned to avoid external stress on the valve.

Resolving a sticking valve is a matter of methodical inspection and addressing the underlying mechanical cause.

Summary Table:

| Primary Cause | Description | Common Fix |

|---|---|---|

| Debris Buildup | Particles embed in the soft PTFE seat, creating friction and obstruction. | Remove valve, clean disc and seat thoroughly. |

| Mechanical Misalignment | Stem or disc is misaligned, causing the disc to scrape against the seat. | Realign valve stem and piping; check for installation stress. |

| Insufficient Lubrication | Dried or contaminated lubricant on stem bearings and actuator. | Apply correct lubricant to stem and actuator components. |

Struggling with unreliable valves? Ensure optimal performance and prevent costly downtime with precision-engineered PTFE components from KINTEK. We specialize in custom fabricating high-quality seals, liners, and labware for the semiconductor, medical, and industrial sectors. From prototypes to high-volume orders, our focus on precision delivers the reliability your processes demand.

Contact KINTEK today for a consultation and let our experts help you solve your fluid handling challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems