At its core, Teflon plastic's role in food processing is to solve the universal problem of stickiness. Made from Polytetrafluoroethylene (PTFE), these sheets and coatings create exceptionally non-stick, heat-resistant, and chemically inert surfaces. This unique combination allows food processing machinery to run more efficiently, reduces waste, simplifies cleanup, and ensures the final product remains safe and uncontaminated.

The true value of Teflon in the food industry is not just one of its properties, but its rare ability to combine elite non-stick performance with high-temperature stability and food-safe chemical inertness, solving critical issues of efficiency and safety simultaneously.

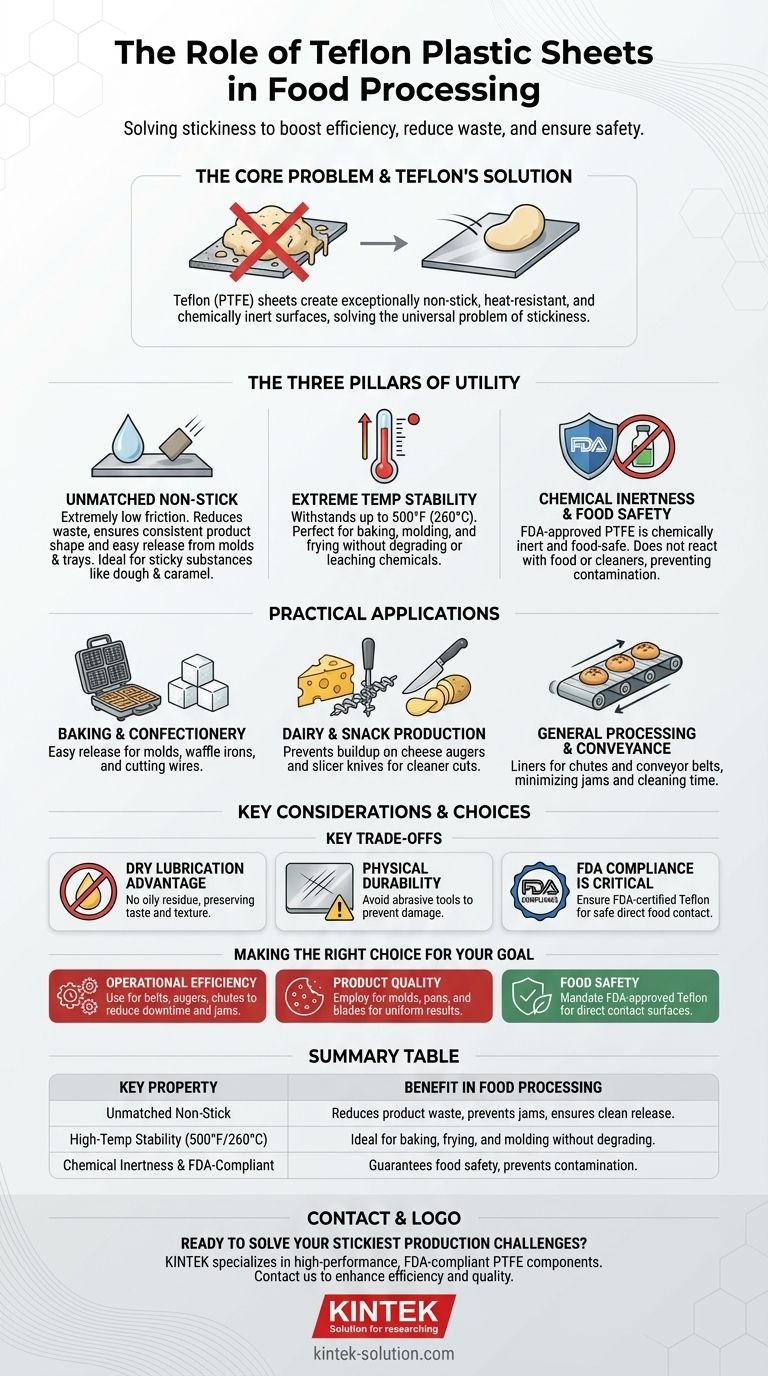

The Three Pillars of Teflon's Utility

Teflon's effectiveness stems from three fundamental characteristics that make it uniquely suited for the demanding environment of food production.

Unmatched Non-Stick Performance

The primary reason Teflon is so widely adopted is its extremely low coefficient of friction. This creates a surface that even the stickiest substances—like dough, caramel, and cheese—struggle to adhere to.

This property directly translates to reduced product waste, as less material is left behind on machinery. It also ensures consistent product shape and easy release from molds and trays.

Extreme Temperature Stability

Teflon (PTFE) sheets can withstand a wide range of temperatures, performing reliably up to 500°F (260°C).

This makes them ideal for direct and indirect contact with food during high-heat processes like baking, molding, and frying without degrading, melting, or leaching harmful chemicals.

Chemical Inertness and Food Safety

Teflon is chemically inert, meaning it does not react with corrosive cleaning agents, oils, fats, or food acids. This resistance prevents the material from breaking down and contaminating the product.

When using FDA-approved Teflon, processors are assured that the material is a food-grade plastic. It will not alter the taste, smell, or consistency of the food it touches, guaranteeing product integrity.

Practical Applications Across the Industry

These core properties are leveraged in countless ways to solve specific production challenges.

Baking and Confectionery

In this sector, easy release is paramount. Teflon is used to coat sugar cube molds, waffle irons, and even the piano wires used to cut uniform cookie dough, preventing buildup and ensuring consistent results.

Dairy and Snack Production

Manufacturers coat cheese augers with Teflon to stop dried cheese crust from building up and jamming equipment. Similarly, coating the knives on potato chip slicers reduces sticky residue, resulting in cleaner, more uniform cuts.

General Processing and Conveyance

Teflon sheets are widely used as liners for chutes, baking sheets, and conveyor belts. This creates a smooth, non-stick path for food products to travel, minimizing jams and making system-wide cleanup significantly faster.

Understanding the Key Trade-offs

While highly effective, it's crucial to understand the context in which Teflon provides the most value.

The Advantage Over Liquid Lubricants

Many non-stick solutions involve wet lubricants like oils or fats. A key advantage of Teflon is that it provides a dry lubrication effect. This means it doesn't add moisture or an oily residue that could alter the food's intended taste, texture, or smell.

The Importance of FDA Compliance

Not all PTFE is created equal. For any food-related application, it is absolutely critical to ensure the Teflon sheet or coating is certified as FDA-compliant. This guarantees it has been manufactured to a standard that is safe for direct food contact.

Physical Durability Considerations

While chemically robust, Teflon is a relatively soft material. In applications with high levels of physical abrasion—such as scraping with metal tools—the coating or sheet can be damaged. Proper handling and cleaning procedures are necessary to maximize its lifespan.

Making the Right Choice for Your Goal

To apply this effectively, align your choice with your primary operational objective.

- If your primary focus is operational efficiency: Use Teflon on conveyor belts, augers, and chutes to reduce product buildup, minimize cleaning downtime, and prevent machinery jams.

- If your primary focus is product quality: Employ Teflon-coated molds, pans, and cutting blades to ensure clean release and uniform shapes, preserving the taste and texture of your product.

- If your primary focus is food safety: Mandate the use of FDA-approved Teflon for any surface in direct contact with food to prevent chemical contamination and ensure regulatory compliance.

Ultimately, Teflon serves as a powerful tool for streamlining food production by creating a stable, safe, and frictionless environment for food to move through.

Summary Table:

| Key Property | Benefit in Food Processing |

|---|---|

| Unmatched Non-Stick | Reduces product waste, prevents machinery jams, ensures clean release. |

| High-Temp Stability (up to 500°F/260°C) | Ideal for baking, frying, and molding without degrading. |

| Chemical Inertness & FDA-Compliant | Guarantees food safety, prevents contamination, and resists cleaning agents. |

Ready to solve your stickiest production challenges with precision-engineered Teflon components?

KINTEK specializes in manufacturing high-performance, FDA-compliant PTFE sheets, seals, liners, and custom labware for the food processing, semiconductor, medical, and laboratory industries. We prioritize precision production to ensure your equipment runs efficiently, reduces waste, and maintains the highest food safety standards.

From custom prototypes to high-volume orders, we provide solutions tailored to your specific needs. Contact KINTEK today to discuss how our Teflon components can enhance your operational efficiency and product quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries