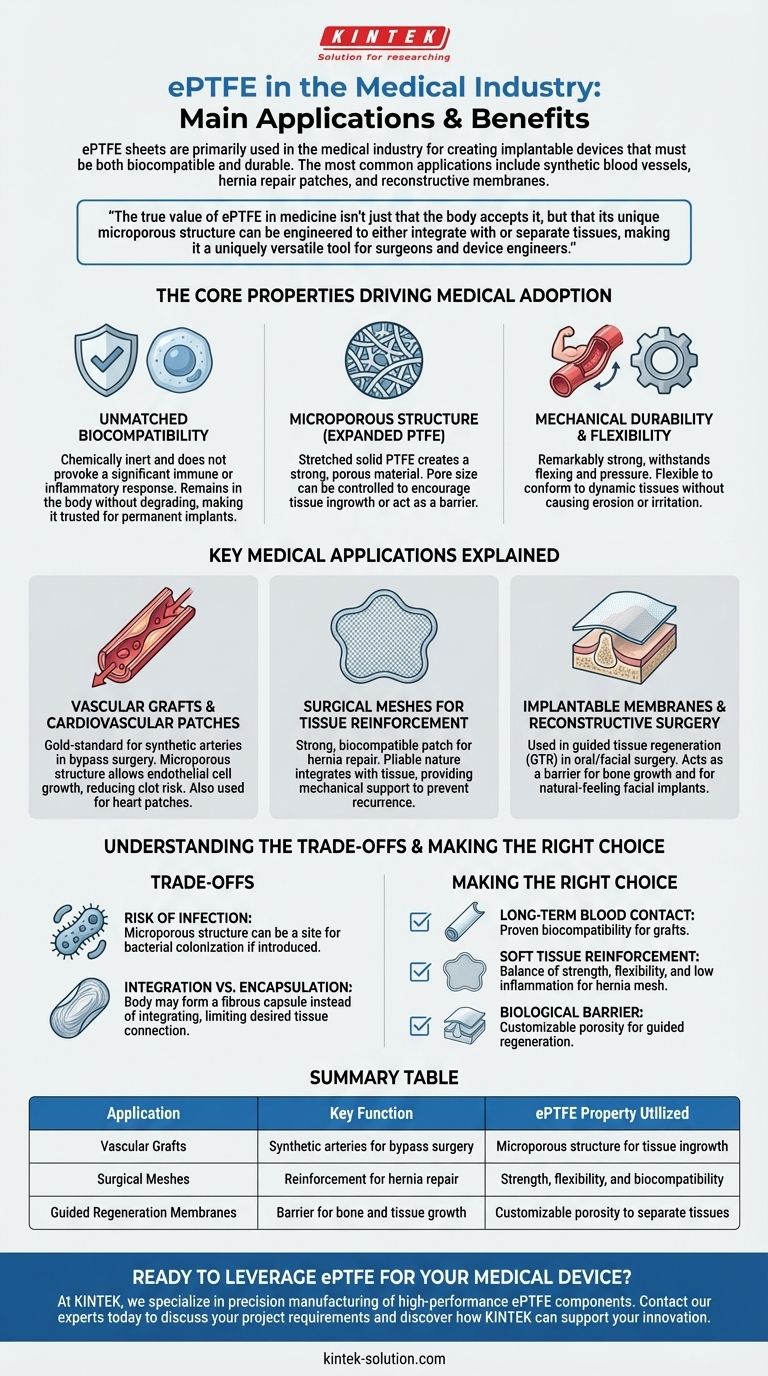

In short, ePTFE sheets are primarily used in the medical industry for creating implantable devices that must be both biocompatible and durable. The most common applications include synthetic blood vessels (vascular grafts), patches for repairing hernias and heart defects (surgical meshes), and membranes for reconstructive surgery.

The true value of ePTFE in medicine isn't just that the body accepts it, but that its unique microporous structure can be engineered to either integrate with or separate tissues, making it a uniquely versatile tool for surgeons and device engineers.

The Core Properties Driving Medical Adoption

The widespread use of ePTFE (expanded Polytetrafluoroethylene) is not accidental. It stems from a combination of physical and biological properties that make it exceptionally well-suited for the demanding environment inside the human body.

Unmatched Biocompatibility

The foundational property of ePTFE is its biocompatibility. This means it is chemically inert and does not provoke a significant immune or inflammatory response from the body's tissues.

This inertness ensures the material can remain in the body for decades without degrading or releasing harmful substances, making it a trusted material for permanent implants.

The "Expanded" Advantage: Microporous Structure

The "e" in ePTFE stands for expanded. During manufacturing, solid PTFE is stretched, creating a strong yet porous material filled with microscopic pores and connecting fibers.

This structure is the key to its versatility. The pore size can be precisely controlled to either encourage tissue ingrowth, as in a vascular graft, or to act as a barrier, as in guided bone regeneration.

Mechanical Durability and Flexibility

Despite being porous, ePTFE is remarkably strong and resistant to mechanical degradation. It can withstand the constant flexing and pressure inside a blood vessel or the stress placed on a hernia repair mesh.

Its flexibility allows it to conform to the soft, dynamic tissues of the body without causing erosion or irritation, which is critical for patient comfort and long-term device success.

Key Medical Applications Explained

These core properties enable ePTFE to be used in a range of life-saving and restorative applications.

Vascular Grafts and Cardiovascular Patches

ePTFE is a gold-standard material for creating synthetic arteries used in bypass surgery. The microporous structure acts as a scaffold, allowing a thin layer of the patient's own endothelial cells to grow on the inner surface, reducing the risk of blood clots.

It is also formed into patches to repair holes in the heart (septal defects) or reconstruct parts of the cardiovascular system.

Surgical Meshes for Tissue Reinforcement

As a surgical mesh, ePTFE sheets provide a strong, biocompatible patch to reinforce weakened abdominal walls in hernia repair.

Its pliable nature allows it to integrate with the surrounding tissue while providing the necessary mechanical support to prevent recurrence.

Implantable Membranes and Reconstructive Surgery

In oral and facial surgery, ePTFE membranes are used for guided tissue regeneration. They act as a barrier that prevents faster-growing soft tissue from invading a space where bone needs to grow.

The material is also used for facial implants, such as those for the chin or cheeks, due to its ability to provide soft, stable augmentation that feels natural.

Understanding the Trade-offs

While ePTFE is a highly effective material, it's essential to understand its limitations. No engineered material is perfect for every situation.

The Risk of Infection

The same microporous structure that encourages tissue ingrowth can also become a potential site for bacteria to colonize. If an infection is introduced during surgery, it can be difficult to eradicate from the implant's complex surface.

Integration vs. Encapsulation

In some cases, instead of integrating with the material, the body may form a smooth, fibrous capsule around the ePTFE implant. While this is part of a normal foreign body response and not a rejection, it can sometimes limit the desired level of tissue integration.

Making the Right Choice for Your Application

The decision to use ePTFE depends entirely on the specific engineering and biological goals of the medical device.

- If your primary focus is long-term blood contact (grafts): ePTFE's proven biocompatibility and ability to foster an endothelial cell layer make it a leading choice.

- If your primary focus is soft tissue reinforcement (hernia mesh): ePTFE provides an excellent balance of strength, flexibility, and a low inflammatory response.

- If your primary focus is creating a biological barrier (guided regeneration): ePTFE's customizable porosity allows you to create a perfect barrier membrane.

Ultimately, ePTFE's unique combination of inertness and structural versatility has cemented its role as a foundational material in the design of modern implantable devices.

Summary Table:

| Application | Key Function | ePTFE Property Utilized |

|---|---|---|

| Vascular Grafts | Synthetic arteries for bypass surgery | Microporous structure for tissue ingrowth |

| Surgical Meshes | Reinforcement for hernia repair | Strength, flexibility, and biocompatibility |

| Guided Regeneration Membranes | Barrier for bone and tissue growth | Customizable porosity to separate tissues |

Ready to leverage ePTFE's unique properties for your medical device?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE and ePTFE components, including custom sheets, seals, and labware. Our expertise in custom fabrication—from prototypes to high-volume production—ensures you get the exact material properties and structural integrity required for demanding medical, semiconductor, and industrial applications.

We understand the critical need for biocompatibility, durability, and controlled porosity in implantable devices. Partner with us to create reliable solutions that meet stringent industry standards.

Contact our experts today to discuss your project requirements and discover how KINTEK can support your innovation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems