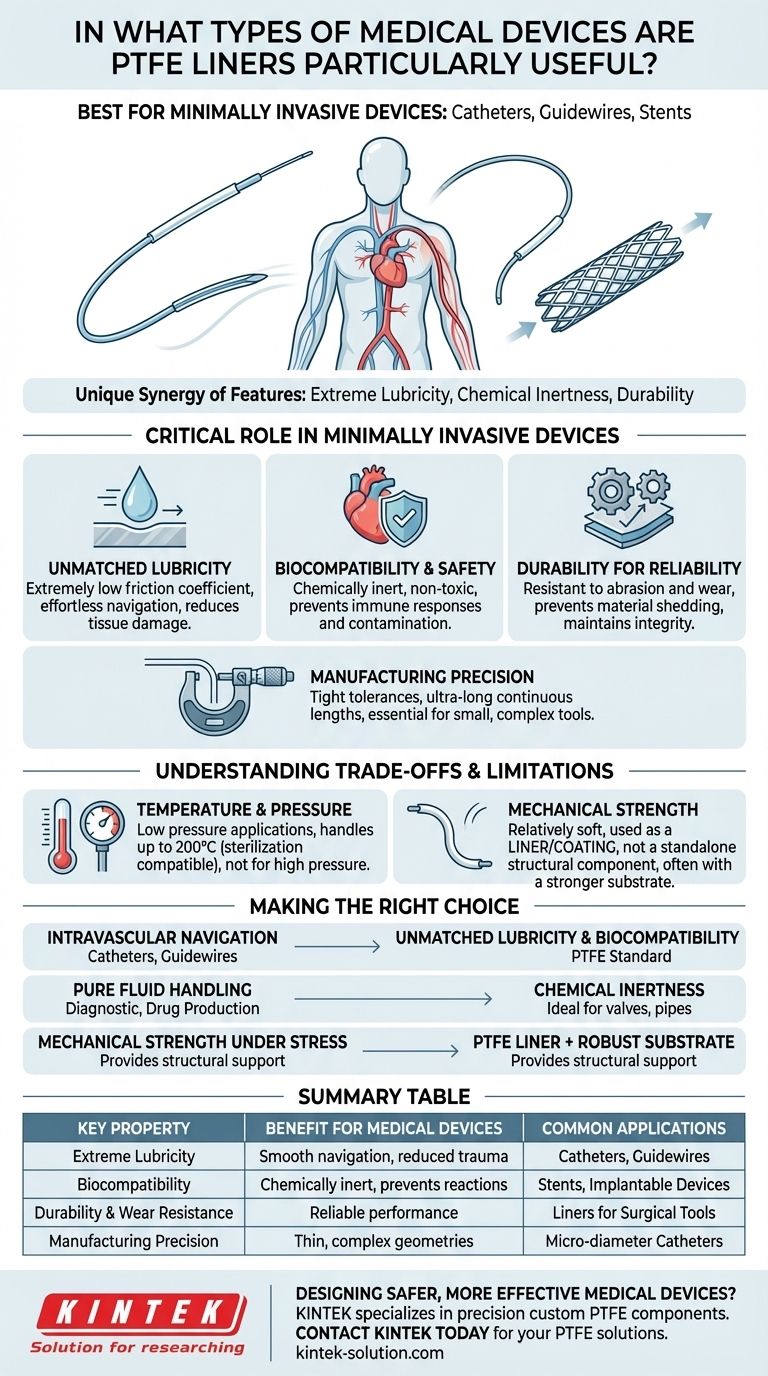

In short, PTFE liners are most useful in minimally invasive medical devices that must navigate delicate internal pathways, such as catheters, guidewires, and stents. Their value comes from a unique combination of extreme lubricity, chemical inertness, and durability, which enables smoother procedures and enhances patient safety.

The core reason PTFE is indispensable in these specific medical applications is not just one property, but its rare synergy of features. It provides an ultra-low-friction surface that is also biocompatible and robust, solving the fundamental challenge of moving a device through the human body with minimal trauma and maximum reliability.

The Critical Role of PTFE in Minimally Invasive Devices

The rise of minimally invasive surgery has created a demand for sophisticated tools that can travel through complex and sensitive anatomical structures, like blood vessels. PTFE's material properties make it uniquely suited to line these devices.

Unmatched Lubricity for Smooth Navigation

The defining characteristic of PTFE is its extremely low coefficient of friction, making its surface exceptionally slippery.

For devices like catheters and guidewires, this property is paramount. The liner allows the device to slide effortlessly through arteries and veins, reducing the force required by the clinician and minimizing damage to vessel walls.

Ensuring Biocompatibility and Patient Safety

Any material placed inside the body must be non-reactive. PTFE is chemically inert and non-toxic.

This means it will not react with blood, tissue, or bodily fluids, preventing adverse immune responses or contamination. Its use in pharmaceutical and food production underscores this high degree of safety.

Durability for Procedural Reliability

Medical procedures demand materials that perform predictably without failure. PTFE liners provide reliable protection against abrasion and wear.

This durability ensures that the liner remains intact throughout a procedure, preventing the risk of material shedding and guaranteeing the device functions as intended from insertion to removal.

Manufacturing Precision for Complex Tools

Many modern medical devices are incredibly small and complex. PTFE can be manufactured into liners with very tight tolerances and in ultra-long, continuous lengths.

This is essential for creating the thin, consistent walls required for small-diameter catheters and guidewires, where even minor imperfections could compromise performance.

Understanding the Trade-offs and Limitations

While PTFE is a remarkable material, it is not a universal solution. Understanding its limitations is key to proper application.

Temperature and Pressure Constraints

PTFE liners perform exceptionally well within a specific operational window. They are suitable for systems with relatively low pressures.

While the material can handle high temperatures up to 200°C—making it compatible with many sterilization methods—it is not intended for high-pressure applications without structural reinforcement.

Considerations for Mechanical Strength

PTFE is a relatively soft polymer. It does not possess the high tensile strength or rigidity of metals or other engineering plastics.

Because of this, it is almost always used as a liner or a coating, not a standalone structural component. It provides the critical surface properties, while a stronger outer material (like a metal braid in a catheter) provides the necessary rigidity and strength.

Making the Right Choice for Your Device

Selecting the right material is a function of your primary engineering goal. PTFE should be a top candidate when surface properties are the main challenge.

- If your primary focus is intravascular navigation (e.g., catheters, guidewires): PTFE is the industry standard due to its unmatched lubricity and proven biocompatibility.

- If your primary focus is pure fluid handling (e.g., diagnostic machines, drug production): PTFE's chemical inertness makes it ideal for lining valves, pipes, and gaskets that contact corrosive or high-purity substances.

- If your primary focus is mechanical strength under high stress: PTFE should be used as a liner in conjunction with a robust substrate that provides the necessary structural support.

By leveraging PTFE for its distinct surface advantages, you can design safer, more effective, and more reliable medical devices.

Summary Table:

| Key Property | Benefit for Medical Devices | Common Applications |

|---|---|---|

| Extreme Lubricity | Enables smooth navigation through blood vessels, reducing trauma. | Catheters, Guidewires |

| Biocompatibility | Chemically inert and non-toxic, preventing adverse reactions. | Stents, Implantable Devices |

| Durability & Wear Resistance | Provides reliable performance throughout procedures. | Liners for Surgical Tools |

| Manufacturing Precision | Can be fabricated into thin, long, and complex geometries. | Micro-diameter Catheters |

Designing a safer, more effective medical device? KINTEK specializes in the precision manufacturing of custom PTFE components, including liners, seals, and labware. Our expertise in working with semiconductor, medical, and laboratory industries ensures your device benefits from the superior lubricity and biocompatibility of PTFE. From initial prototypes to high-volume production, we deliver the precision and reliability your project demands.

Contact KINTEK today to discuss how our custom PTFE solutions can enhance your medical device performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries