The primary advantages of PTFE mechanical seals are their unparalleled chemical resistance, their ability to perform reliably across an exceptionally wide range of temperatures and pressures, and their inherently low friction coefficient which reduces wear and energy consumption. These properties make them the default choice for the most demanding applications where other materials would quickly fail.

The decision to use a PTFE mechanical seal is a decision for operational resilience. While other materials may suffice in standard conditions, PTFE provides a unique combination of chemical inertness and robust performance that ensures reliability and longevity in aggressive, high-purity, or extreme temperature environments.

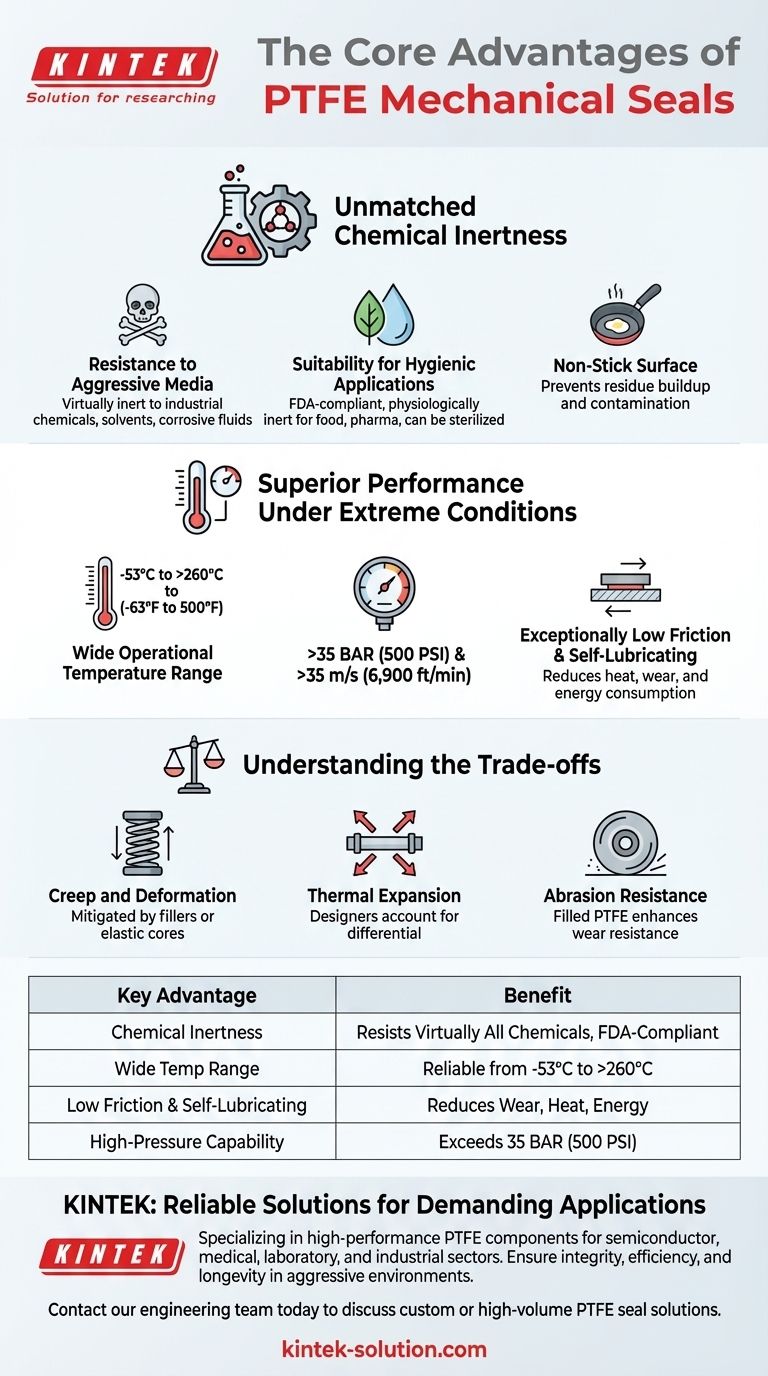

The Core Advantage: Unmatched Chemical Inertness

Polytetrafluoroethylene (PTFE) is often called the "king of plastics" for its remarkable resistance to chemical attack. This single property is the foundation for many of its most critical applications.

Resistance to Aggressive Media

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it an essential material for seals used in chemical processing, pharmaceuticals, and any system handling corrosive or reactive fluids. Its long-term durability in these media is unmatched.

Suitability for Hygienic Applications

Many grades of PTFE are FDA-compliant and physiologically inert, meaning they are safe for direct contact with food, beverages, and pharmaceutical products. They can also be effectively sterilized, ensuring the purity of the process media is never compromised.

Non-Stick Surface

The non-adhesive nature of PTFE prevents process media from sticking to the seal faces. This quality is critical for preventing residue buildup, which can interfere with sealing performance and contaminate the product.

Superior Performance Under Extreme Conditions

Beyond its chemical properties, PTFE delivers exceptional mechanical performance, especially when conditions become challenging for conventional elastomers or plastics.

Wide Operational Temperature Range

PTFE seals maintain their integrity and sealing capability across a vast temperature spectrum, typically from -53°C to over 232°C (-63°F to 450°F), with some variants reaching 260°C (500°F).

High Pressure and Speed Capability

Engineered PTFE seals can handle significant pressures, often exceeding 35 BAR (500 PSI). They are also suitable for high-speed rotating equipment, with some designs capable of handling surface speeds of 35 m/s (6,900 ft/min) or more.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property reduces heat generation, minimizes wear on the seal and shaft, and lowers the energy required to operate the equipment, improving overall efficiency.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its inherent limitations and how modern seal designs compensate for them.

Creep and Deformation

Under sustained pressure and temperature, pure PTFE can be susceptible to "creep" or "cold flow." Modern PTFE seals mitigate this by incorporating fillers (like glass, carbon, or bronze) or using an elastic inner core that provides constant pressure and improves sealing effectiveness.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. Seal designers must account for this differential to ensure a reliable seal is maintained across the entire operating temperature range.

Abrasion Resistance

While durable, pure PTFE may not be the ideal choice for sealing against highly abrasive media. However, filled PTFE compounds are often used to significantly enhance wear resistance in these applications.

Making the Right Choice for Your Application

Selecting the right seal material is about aligning its properties with your specific operational goals.

- If your primary focus is handling aggressive chemicals or ensuring product purity: The unparalleled chemical inertness and FDA-compliant grades of PTFE make it the safest and most reliable choice.

- If your primary focus is performance in extreme temperatures or high-speed equipment: PTFE's wide operational temperature range and low-friction characteristics provide durability where elastomers would degrade.

- If your primary focus is reducing maintenance and long-term costs: The extended service life, reduced wear, and high reliability of PTFE seals in demanding environments lead to lower operating costs over time.

Ultimately, choosing a PTFE mechanical seal is an investment in system integrity for your most critical and challenging applications.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, solvents, and is FDA-compliant for high-purity applications. |

| Wide Temperature Range | Performs reliably from -53°C to over 260°C (-63°F to 500°F). |

| Low Friction & Self-Lubricating | Reduces wear, heat generation, and energy consumption. |

| High-Pressure Capability | Engineered seals can handle pressures exceeding 35 BAR (500 PSI). |

Need a reliable seal for a demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including mechanical seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates with maximum integrity, efficiency, and longevity, even in the most aggressive environments.

Contact our engineering team today to discuss your specific requirements for custom or high-volume PTFE seal solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the sealing capabilities of PTFE lined check valves? Achieve Superior Corrosion Resistance

- What factors should be considered when selecting Teflon bearings? Match Your Application's Demands for Reliability

- What are the primary functions of PTFE expansion bellows? Absorb Movement, Dampen Vibration, and Protect Pipes

- What are the advantages of Teflon sheets? Superior Performance in Harsh Environments

- What makes PTFE envelope gaskets resistant to contamination? The Key to Process Purity and Chemical Inertness

- Why is PTFE considered a safe choice for O-ring seals? Ensure Reliability in Extreme Conditions

- What are the tensile strength properties of PTFE? Leveraging Flexibility and Chemical Resistance

- What are the two main types of specialty PTFE washers and their characteristics? Choose the Right Washer for Your Application