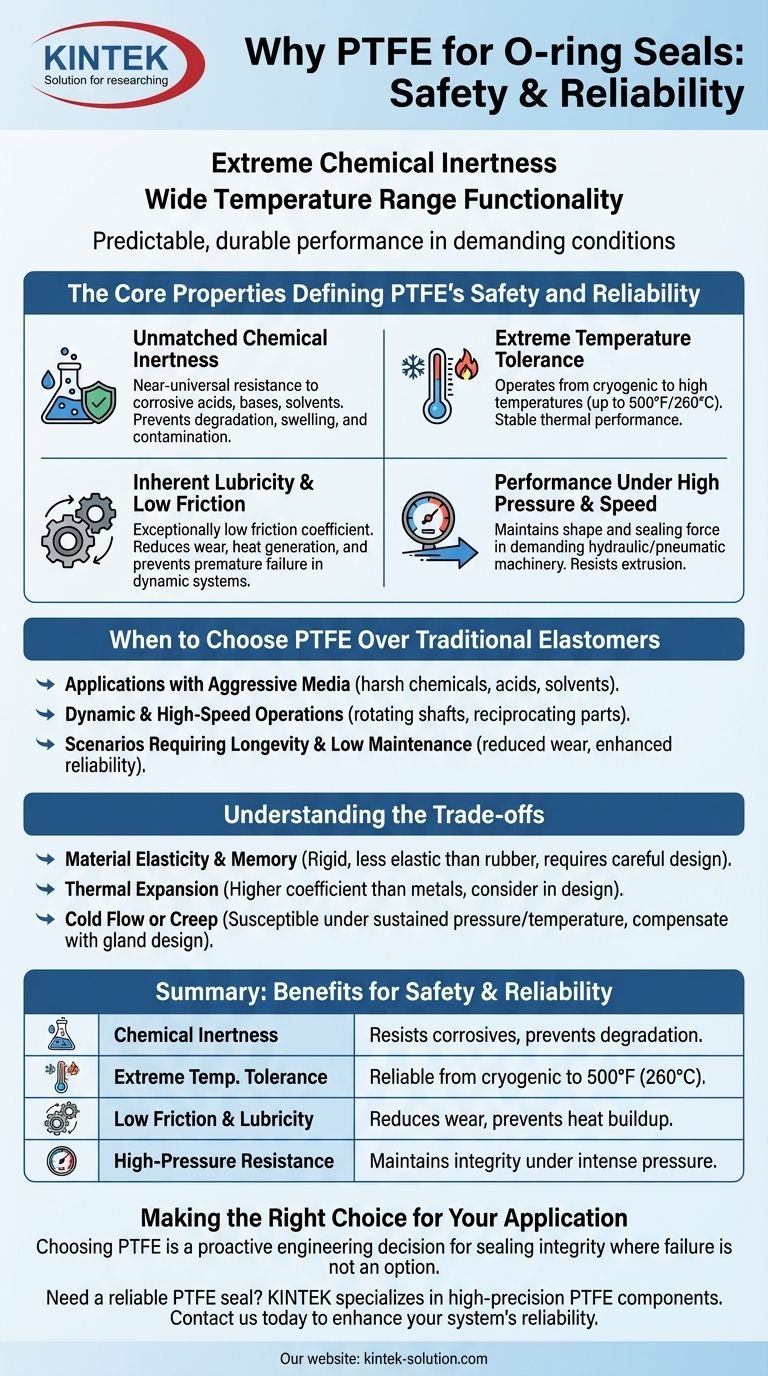

In engineering applications, PTFE is considered a safe and reliable choice for O-ring seals due to two primary characteristics: its extreme chemical inertness and its ability to function across a vast range of temperatures. This unique combination ensures the seal maintains its integrity without degrading or contaminating the system, even when exposed to aggressive chemicals or thermal extremes that would cause conventional materials to fail.

The core reason for PTFE's reputation for safety is not just its material properties in isolation, but its predictable and durable performance under demanding conditions where the failure of a seal could lead to critical system damage or safety hazards.

The Core Properties Defining PTFE's Safety and Reliability

The safety of a component is directly tied to its reliability. In the case of PTFE seals, several inherent properties contribute to their robust and predictable performance in critical applications.

Unmatched Chemical Inertness

PTFE exhibits near-universal chemical resistance. It is compatible with a vast array of sealed media, including corrosive acids, bases, and solvents that would quickly degrade traditional elastomeric seals.

This property is a critical safety feature, as it prevents the seal from breaking down, swelling, or contaminating the process fluid.

Extreme Temperature Tolerance

PTFE seals operate effectively across a wide thermal spectrum, from cryogenic lows to high-temperature highs.

While signs of thermal decomposition can appear around 392°F (200°C), significant degradation only begins above 500°F (260°C). This high threshold ensures a stable and reliable seal in applications where temperature fluctuations are common, far exceeding the capabilities of most rubbers.

Inherent Lubricity and Low Friction

PTFE has an exceptionally low coefficient of friction, one of the lowest of any solid material. This provides excellent natural lubricity without the need for external lubricants.

In dynamic applications, such as in rotary or hydraulic systems, this property minimizes friction and heat generation. This reduces wear and tear on both the seal and mating components, enhancing operational lifespan and preventing premature failure.

Performance Under High Pressure and Speed

PTFE's robust physical structure allows it to withstand highly intense pressures and high-speed applications.

Unlike more flexible elastomers that can extrude or wear away under such conditions, PTFE maintains its shape and sealing force, ensuring a reliable seal in demanding hydraulic and pneumatic machinery. It can even be used in applications requiring dry running without suffering damage.

When to Choose PTFE Over Traditional Elastomers

While standard elastomeric O-rings are suitable for many tasks, PTFE becomes the necessary choice when operational parameters exceed the limits of rubber. Its selection is often a deliberate engineering decision to mitigate risk.

Applications with Aggressive Media

When sealing systems involve harsh chemicals, acids, or solvents, PTFE is the default safe choice. Its chemical inertness guarantees seal integrity where an elastomer would rapidly deteriorate.

Dynamic and High-Speed Operations

For rotating shafts or high-speed reciprocating parts, the low-friction nature of PTFE prevents the wear, heat buildup, and stick-slip phenomenon that can cause elastomeric seals to fail.

Scenarios Requiring Longevity and Low Maintenance

The durability of PTFE in extreme conditions translates directly to a longer service life and reduced maintenance frequency. This enhances overall system reliability and lowers long-term operating costs.

Understanding the Trade-offs

No material is perfect for every situation. Understanding the limitations of PTFE is crucial for proper application and ensuring safety.

Material Elasticity and Memory

PTFE is a relatively rigid plastic and lacks the "memory" or elasticity of rubber. Once compressed or stretched, it does not readily return to its original shape.

This characteristic can make installation more challenging and requires careful design of the seal gland to ensure a constant sealing force is maintained.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion compared to many metals. This must be accounted for in the design process, especially in applications with wide temperature swings, to prevent loss of sealing pressure.

Cold Flow or Creep

Under sustained pressure and temperature, PTFE can be susceptible to "creep," or gradual deformation over time. This is a key consideration in high-pressure static sealing applications where bolt torque and gland design must compensate for this effect.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical step in ensuring the safety and reliability of your system. Your primary operational goal should guide your decision.

- If your primary focus is sealing aggressive chemicals or operating in extreme temperatures: PTFE's inertness and thermal stability make it the definitive choice for maximum safety and longevity.

- If your primary focus is high-speed or dynamic sealing with low friction: PTFE's inherent lubricity prevents wear and ensures smooth, reliable operation where elastomers would quickly fail.

- If your primary focus is standard static sealing in a benign environment: A traditional elastomeric O-ring is often a more cost-effective and forgiving material for installation.

Ultimately, choosing PTFE is a proactive engineering decision to ensure sealing integrity in applications where failure is not an option.

Summary Table:

| Property | Benefit for Safety & Reliability |

|---|---|

| Chemical Inertness | Resists corrosive acids, bases, and solvents, preventing degradation and contamination. |

| Extreme Temperature Tolerance | Functions reliably from cryogenic temperatures up to 500°F (260°C). |

| Low Friction & Lubricity | Reduces wear in dynamic applications, preventing heat buildup and failure. |

| High-Pressure Resistance | Maintains seal integrity under intense pressures where elastomers would extrude. |

Need a reliable PTFE seal for your critical application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication—from prototypes to high-volume orders—ensures you get a seal that guarantees safety and performance in the most demanding environments.

Contact us today to discuss your specific requirements and let our expertise enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications