In short, Teflon sheets offer a unique combination of advantages that make them superior to conventional materials in specific, demanding environments. Their primary benefits are exceptional chemical inertness, high-temperature resistance, and an extremely low-friction, non-stick surface, allowing them to function where metals would corrode and rubber would degrade.

The decision to use Teflon over metal or rubber is not about universal superiority, but about selecting the right tool for the job. Teflon excels in harsh environments where chemical, thermal, and surface properties are more critical than raw structural strength.

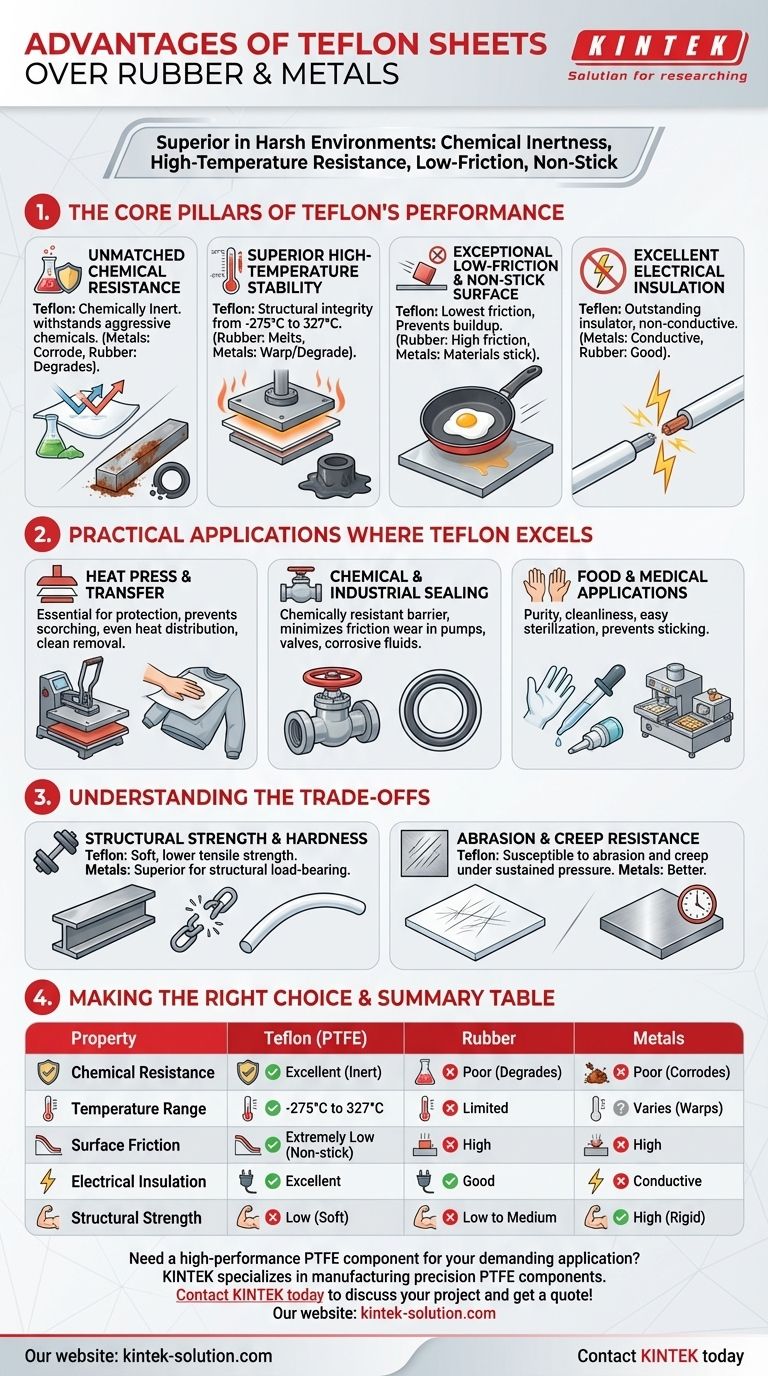

The Core Pillars of Teflon's Performance

To understand why Teflon is chosen, we must look at its fundamental material properties. These three pillars explain its effectiveness in applications where other materials fail.

Unmatched Chemical Resistance

Metals are highly susceptible to oxidation and corrosion, especially in acidic or moist environments. Many types of rubber will quickly deteriorate when exposed to solvents.

Teflon (PTFE), however, is almost entirely chemically inert. It can withstand a vast range of aggressive chemicals, providing a durable and reliable barrier where both metals and rubber would fail.

Superior High-Temperature Stability

Teflon maintains its structural integrity across an exceptionally wide temperature range, typically from -275°C up to 327°C (-450°F to 620°F).

This thermal resistance makes it invaluable for high-temperature processes, such as heat pressing, where rubber would melt and certain metals might warp or degrade.

Exceptional Low-Friction and Non-Stick Surface

Teflon possesses one of the lowest coefficients of friction of any known solid material. This creates its signature non-stick quality.

In practical terms, this means materials don't adhere to its surface, preventing buildup and allowing for easy cleaning or removal. In dynamic applications like O-rings or seals, this low friction minimizes wear and ensures smooth operation.

Excellent Electrical Insulation

Beyond its other properties, Teflon is also an outstanding electrical insulator. This makes it a critical component in various electronics and wiring applications where preventing electrical conductivity is essential.

Practical Applications Where Teflon Excels

These core properties translate directly into clear advantages in real-world scenarios.

In Heat Press and Transfer Processes

Teflon sheets are essential for protecting both the garment and the heat press platen. The sheet prevents scorching by distributing heat evenly.

Its non-stick surface ensures that inks, dyes, or adhesives do not transfer onto the equipment, and it allows the garment to be removed cleanly after pressing.

In Chemical and Industrial Sealing

For dynamic applications like seals and O-rings, Teflon provides a chemically resistant barrier that also minimizes wear due to friction.

This dual benefit ensures a longer lifespan and more reliable performance in pumps, valves, and other equipment handling corrosive fluids.

In Food and Medical Applications

Because of its chemical inertness and non-stick properties, Teflon is widely used where purity and cleanliness are paramount. It is easy to sterilize and prevents materials from sticking, which is critical in processing equipment.

Understanding the Trade-offs

While Teflon's advantages are significant, it is not a universal replacement for metals or rubber. Understanding its limitations is key to using it correctly.

Structural Strength and Hardness

Teflon is a relatively soft material compared to metals. It does not possess the tensile strength, rigidity, or load-bearing capacity of steel or aluminum. For applications requiring high structural integrity, metal is the superior choice.

Abrasion and Creep Resistance

While its low friction minimizes wear in many cases, Teflon can be susceptible to abrasion from sharp or hard particles. It can also experience "creep," a slow deformation under sustained pressure, more so than metals.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary goal.

- If your primary focus is operating in harsh chemical environments: Teflon's inertness makes it the definitive choice over metals that corrode and rubbers that dissolve.

- If your primary focus is high-temperature performance: Teflon provides stability at temperatures that would destroy most elastomers and rubbers.

- If your primary focus is a non-stick surface or low friction: Teflon's exceptionally low friction coefficient is ideal for applications like heat pressing, clean-release surfaces, or dynamic seals.

- If your primary focus is structural strength and load-bearing: Metals remain the superior choice for any application where rigidity and strength are the most critical factors.

By understanding these core properties and trade-offs, you can confidently select the material that delivers the precise performance your application demands.

Summary Table:

| Property | Teflon (PTFE) | Rubber | Metals |

|---|---|---|---|

| Chemical Resistance | Excellent (Chemically inert) | Poor (Degrades with solvents) | Poor (Susceptible to corrosion) |

| Temperature Range | -275°C to 327°C (-450°F to 620°F) | Limited | Varies, can warp/degrade |

| Surface Friction | Extremely Low (Non-stick) | High | High |

| Electrical Insulation | Excellent | Good | Conductive |

| Structural Strength | Low (Soft) | Low to Medium | High (Rigid) |

Need a high-performance PTFE component for your demanding application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for industries where failure is not an option. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide the chemical inertness, thermal stability, and non-stick performance your processes require.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact solution for your unique challenges.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support