The fundamental reason PTFE envelope gaskets resist contamination is their profound chemical inertness. This property stems from the material's unique molecular structure, which makes it non-reactive with virtually all chemicals across the entire pH spectrum. Because the gasket material does not degrade, leach, or react with the process media, it ensures the purity of the end product.

The core takeaway is that contamination resistance is not an added feature but an inherent property of Polytetrafluoroethylene (PTFE). Its chemical stability prevents the gasket itself from becoming a source of contamination, a critical requirement in sensitive industries like pharmaceuticals, food processing, and fine chemical production.

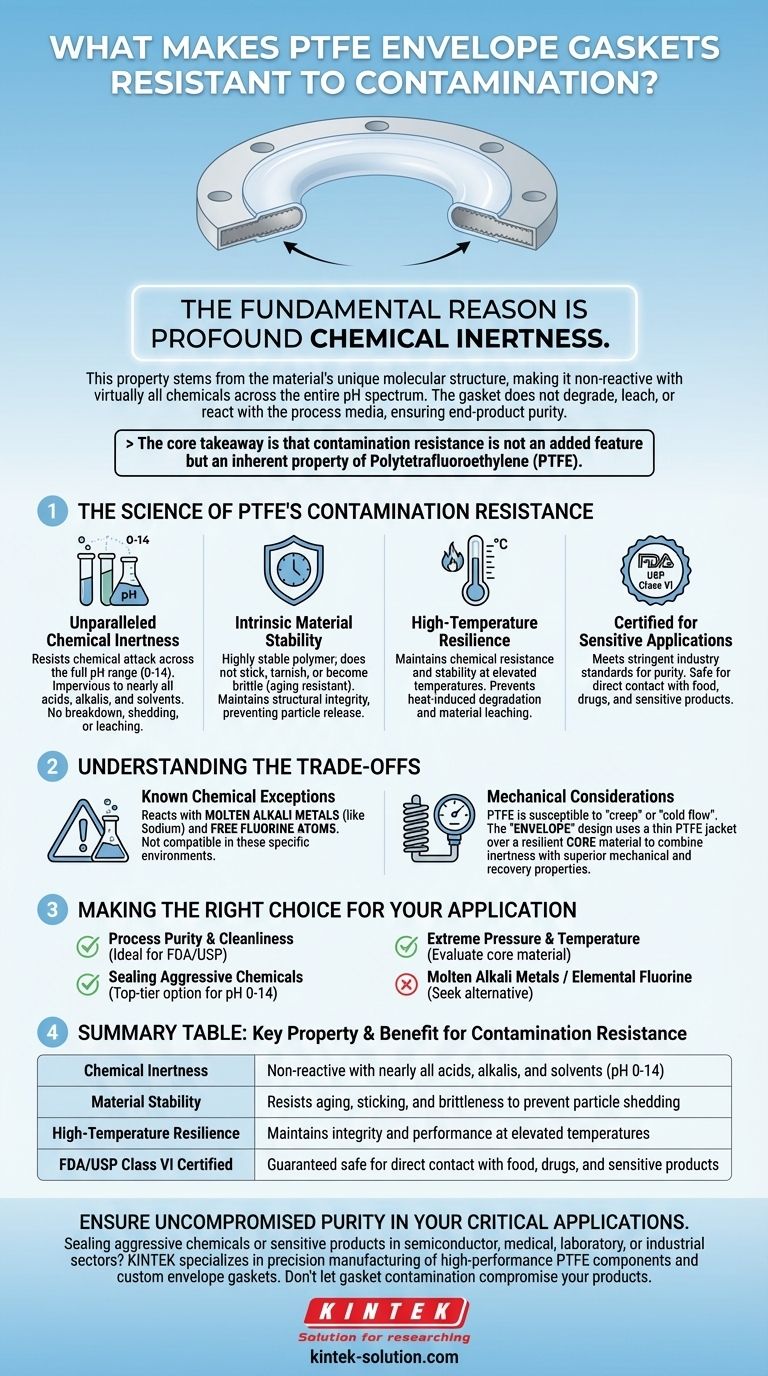

The Science of PTFE's Contamination Resistance

To understand why these gaskets are so effective, we must look at the specific properties of the PTFE material used in their construction.

Unparalleled Chemical Inertness

The defining characteristic of PTFE is its resistance to chemical attack. It can effectively seal media across the full pH range of 0-14, meaning it is impervious to nearly all acids, alkalis, and solvents.

This non-reactivity ensures that the gasket material will not break down and shed particles or leach chemical compounds into the process flow, which is the primary mechanism of gasket-related contamination.

Intrinsic Material Stability

PTFE is a highly stable polymer. It does not stick, tarnish, or become brittle over time when exposed to aggressive media, a process known as aging.

This long-term stability means the gasket maintains its structural integrity. A stable gasket does not degrade and release fragments into the system, preserving the purity of the substance being sealed.

High-Temperature Resilience

Many materials begin to break down or react when subjected to high temperatures. PTFE, however, maintains its chemical resistance and stability even at elevated temperatures.

This thermal resilience prevents heat-induced degradation, which is another common cause of material leaching and subsequent product contamination.

Certified for Sensitive Applications

The material properties of PTFE allow it to meet stringent industry standards for purity. These gaskets often comply with FDA and USP Class VI regulations.

These certifications are an independent validation that the material is safe for direct contact with food, drugs, and other products intended for human use, providing a formal guarantee against contamination.

Understanding the Trade-offs

While PTFE offers exceptional chemical performance, it's important to understand its limitations to make an informed decision.

Known Chemical Exceptions

Despite its broad resistance, PTFE is not compatible with all substances. It is known to react with molten alkali metals (like sodium) and free fluorine atoms. In these specific, highly reactive environments, a different sealing material must be chosen.

Mechanical Considerations

PTFE is a relatively soft material susceptible to "creep" or "cold flow" under pressure. The "envelope" design addresses this by using a thin PTFE jacket over a more resilient, compressible core material.

This composite structure combines the chemical inertness of the PTFE surface with the superior mechanical and recovery properties of the core, providing a reliable and tight seal that prevents leaks without the typical drawbacks of a solid PTFE gasket.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its properties to your operational goals.

- If your primary focus is process purity and cleanliness: A PTFE envelope gasket is an ideal choice due to its non-leaching, non-reactive nature and compliance with FDA/USP standards.

- If your primary focus is sealing aggressive or corrosive chemicals: This gasket is a top-tier option, as its ability to withstand the full pH range ensures long service life and system integrity.

- If your primary focus is extreme pressure and temperature dynamics: You must evaluate the core material of the envelope gasket, as it dictates the seal's mechanical performance and recovery.

- If you are working with molten alkali metals or elemental fluorine: You must seek an alternative sealing material specifically designed for those highly reactive agents.

By understanding these core principles, you can confidently determine where a PTFE envelope gasket will provide the highest level of safety and purity for your system.

Summary Table:

| Key Property | Benefit for Contamination Resistance |

|---|---|

| Chemical Inertness | Non-reactive with nearly all acids, alkalis, and solvents (pH 0-14) |

| Material Stability | Resists aging, sticking, and brittleness to prevent particle shedding |

| High-Temperature Resilience | Maintains integrity and performance at elevated temperatures |

| FDA/USP Class VI Certified | Guaranteed safe for direct contact with food, drugs, and sensitive products |

Ensure Uncompromised Purity in Your Critical Applications

Are you sealing aggressive chemicals or handling sensitive products in the semiconductor, medical, laboratory, or industrial sectors? The inherent contamination resistance of PTFE is essential for protecting your process integrity and final product quality.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom envelope gaskets. We understand the critical need for reliability and purity in your operations. Whether you require prototypes or high-volume orders, our expertise in custom PTFE fabrication ensures you get a sealing solution tailored to your specific chemical, temperature, and pressure requirements.

Don't let gasket contamination compromise your products. Contact KINTEK today to discuss your application needs and learn how our PTFE solutions can safeguard your processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE lined valves? Control Corrosive & High-Purity Fluids

- How do PTFE O-rings differ from rubber O-rings in terms of compliance? Understanding Rigidity vs. Elasticity

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is Teflon suitable for bridge bearing pads? Unlock Smooth, Durable Movement for Your Structure

- How can PTFE's properties be enhanced? Boost Performance with Filled PTFE Composites

- What are some common applications of machined Teflon? Critical Components for Harsh Environments

- What are the drawbacks of PTFE seals? Key Limitations and Design Considerations

- Why is PTFE ideal for aerospace applications? The Ultimate Material for Extreme Conditions