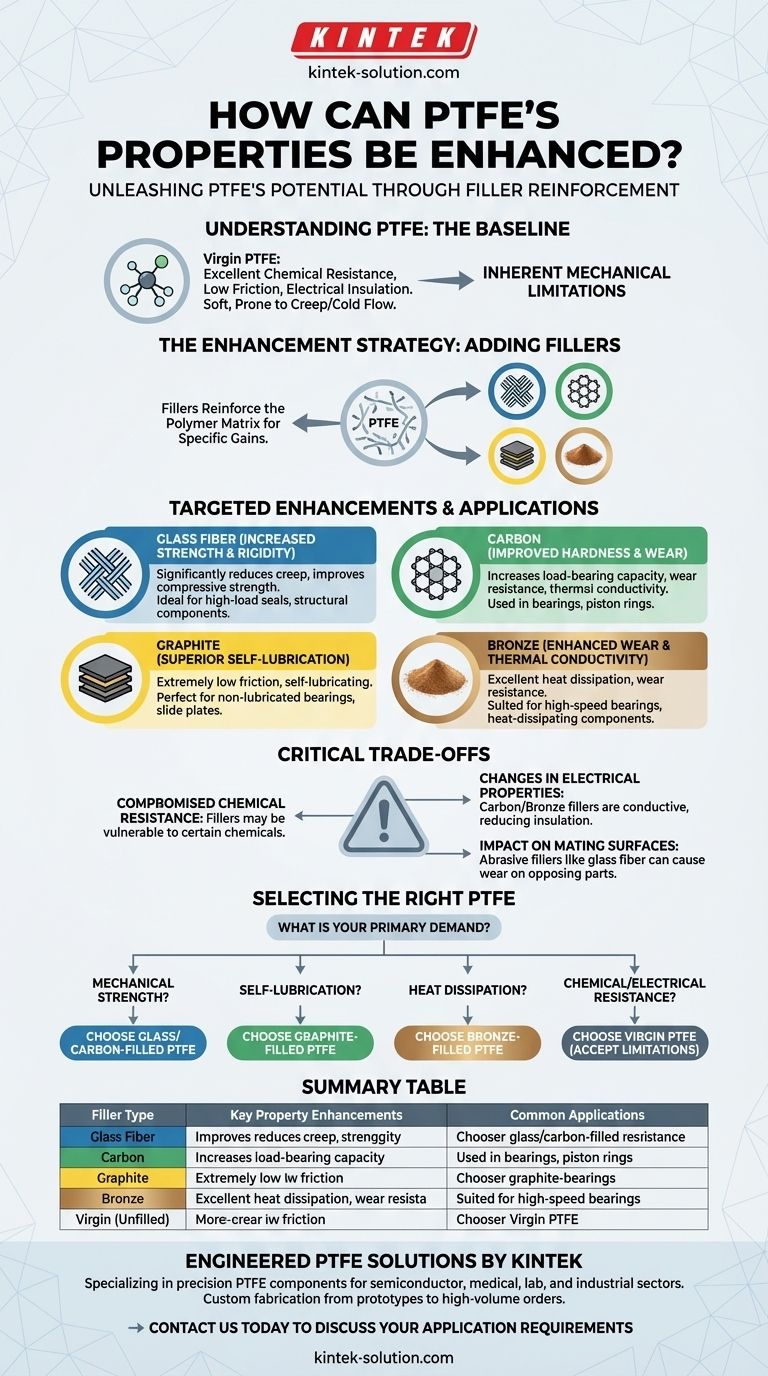

To enhance the properties of Polytetrafluoroethylene (PTFE), the standard industrial practice is to create a composite material by blending it with specific fillers. These additives overcome PTFE's inherent softness by reinforcing its polymer matrix. The most common fillers include glass fibers, carbon, graphite, and bronze, which are added to improve mechanical characteristics like hardness, wear resistance, and compressive strength.

While pure PTFE offers exceptional chemical inertness and low friction, it is a mechanically soft material prone to deformation under load. The key to unlocking its potential for demanding applications lies in reinforcing it with fillers to improve specific mechanical properties like strength, stability, and wear resistance.

Understanding PTFE's Inherent Profile

To appreciate the impact of enhancements, we must first establish the baseline properties of pure, or "virgin," PTFE.

A Profile of Virgin PTFE

Virgin PTFE is a remarkable fluoropolymer known for its extreme chemical resistance and stability across a wide temperature range, typically from -190°C to +260°C.

Its key strengths include a very low coefficient of friction (making it non-stick), excellent electrical insulation, and near-zero water absorption. These properties make it ideal for non-load-bearing seals, insulators, and linings in corrosive environments.

The Core Mechanical Limitations

The primary drawback of virgin PTFE is its poor mechanical performance. It is soft and exhibits a phenomenon known as creep, or cold flow, where the material slowly deforms under sustained pressure.

Its resistance to wear and abrasion is only moderate, limiting its use in dynamic applications that involve significant friction or physical stress.

The Role of Fillers in PTFE Enhancement

Adding fillers is the most effective method for targeting PTFE's mechanical weaknesses. Each filler imparts a distinct set of characteristics to the final composite material.

Enhancing with Glass Fiber

Glass fibers are a common filler used to drastically improve compressive strength and rigidity.

Glass-filled PTFE exhibits significantly reduced creep and better resistance to deformation under load. It also offers enhanced wear resistance compared to virgin PTFE.

Enhancing with Carbon

The addition of carbon powder or fiber increases hardness, load-bearing capacity, and wear resistance.

Carbon-filled PTFE often has good thermal conductivity, helping to dissipate heat from wearing surfaces. It also maintains good chemical resistance in non-oxidizing environments.

Enhancing with Graphite

Graphite is used primarily to improve lubrication properties.

A graphite-filled PTFE compound has an extremely low coefficient of friction, making it an excellent self-lubricating material for non-lubricated bearings, slide plates, and seals.

Enhancing with Bronze

Bronze powder significantly increases wear resistance and thermal conductivity.

This makes bronze-filled PTFE suitable for applications requiring high mechanical strength and the ability to dissipate frictional heat quickly, such as in high-speed bearing applications.

Understanding the Trade-offs of Filled PTFE

Enhancing one property of PTFE with a filler almost always involves a compromise in another. It is critical to understand these trade-offs to select the correct material.

Compromised Chemical Resistance

The primary trade-off is a reduction in chemical inertness. The fillers themselves are not as chemically resistant as the PTFE matrix. A chemical that does not affect PTFE may attack the glass, carbon, or bronze filler within the material.

Changes in Electrical Properties

Virgin PTFE is an excellent electrical insulator. However, fillers like carbon and bronze are conductive. Adding them to PTFE will significantly degrade its dielectric strength and insulating capabilities, making it unsuitable for many electrical applications.

Impact on Mating Surfaces

While fillers improve the wear resistance of the PTFE part itself, some abrasive fillers like glass fiber can cause increased wear on the opposing surface (the "mating surface"). This must be considered in the overall system design.

Selecting the Right PTFE for Your Application

Your choice of material must be driven by the most critical demand of your application.

- If your primary focus is mechanical strength and rigidity: Choose a glass-filled or carbon-filled PTFE to resist deformation and compression under load.

- If your primary focus is self-lubrication and low friction: Select a graphite-filled PTFE, especially for non-lubricated bearings or slide plates.

- If your primary focus is heat dissipation and wear resistance: A bronze-filled PTFE is the optimal choice for improving thermal conductivity in high-wear components.

- If your primary focus is maximum chemical and electrical resistance: You must use virgin (unfilled) PTFE, accepting its inherent mechanical limitations.

By understanding these targeted enhancements, you can transform a versatile polymer into a high-performance material precisely engineered for your specific challenge.

Summary Table:

| Filler Type | Key Property Enhancements | Common Applications |

|---|---|---|

| Glass Fiber | Increased compressive strength, rigidity, reduced creep | High-load seals, structural components |

| Carbon | Improved hardness, load-bearing capacity, wear resistance | Bearings, piston rings, mechanical parts |

| Graphite | Superior self-lubrication, extremely low friction | Non-lubricated bearings, slide plates |

| Bronze | Enhanced wear resistance, excellent thermal conductivity | High-speed bearings, heat-dissipating components |

| Virgin (Unfilled) | Maximum chemical/electrical resistance, low friction | Chemical seals, electrical insulators, linings |

Need a PTFE component engineered for your specific challenges?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the mechanical strength of glass-filled PTFE, the self-lubrication of graphite-filled composites, or the pure chemical resistance of virgin PTFE, our custom fabrication services deliver optimal performance from prototypes to high-volume orders.

Contact us today to discuss your application requirements and let our experts help you select or custom-formulate the perfect PTFE material for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the thermal properties of PTFE that make it ideal for seals? Ensuring Reliability in Extreme Conditions

- What are the main advantages of expanded PTFE gaskets? Superior Sealing for Demanding Industrial Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- How does Teflon benefit the fabric and carpet industry? Achieve Superior Stain Resistance

- In what medical applications are PTFE Liners commonly used? Enhancing Device Performance & Patient Safety

- What are PTFE O-rings and their properties? A Guide to High-Performance Sealing

- What are some potential drawbacks of using Teflon sheets? Heat Transfer, Slippage & Safety Risks

- Why is the non-stick property of Teflon sheets advantageous? Boost Efficiency & Reduce Waste