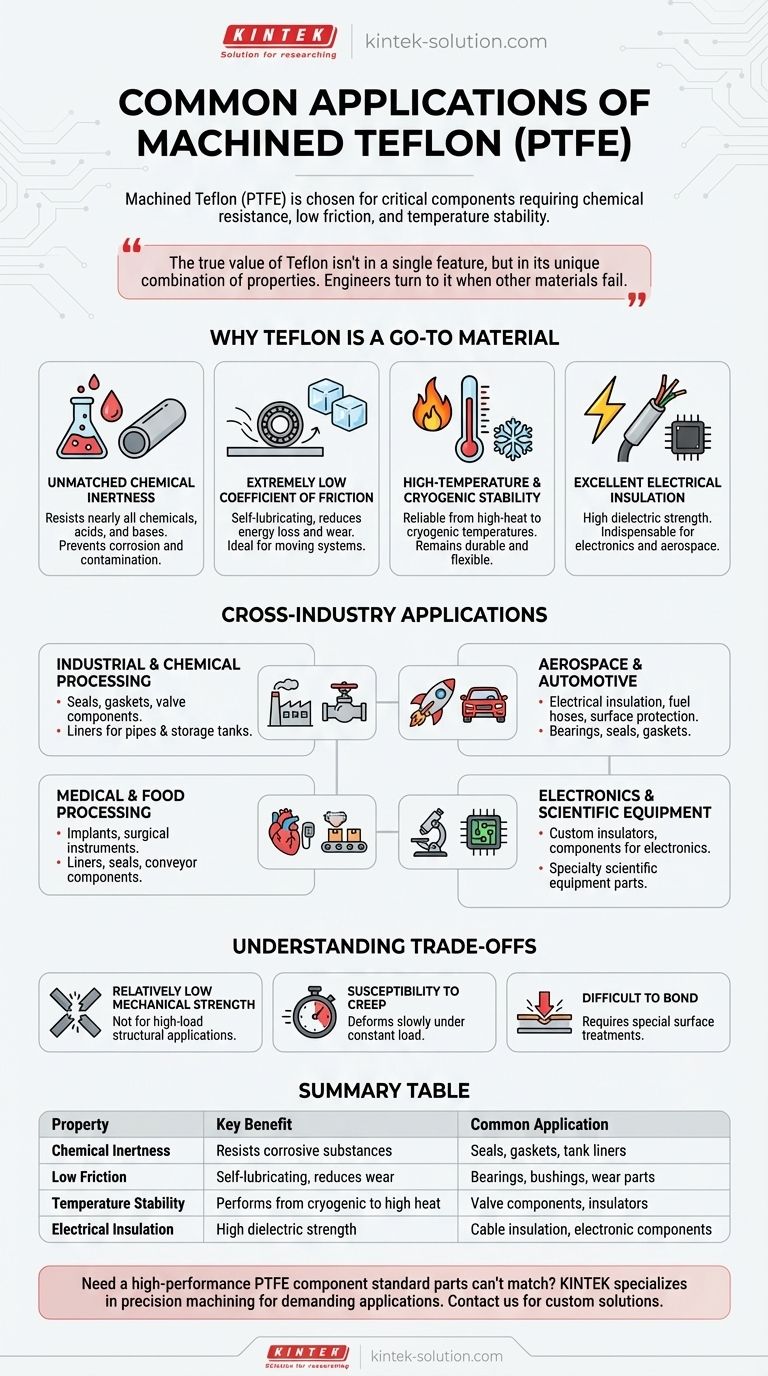

In short, machined Teflon (PTFE) is used for critical components where chemical resistance, low friction, and temperature stability are non-negotiable. Its most common applications include high-performance seals, gaskets, bearings, electrical insulators, and biocompatible parts for the medical and food processing industries.

The true value of Teflon isn't in a single feature, but in its unique combination of properties. Engineers turn to machined Teflon when other materials fail due to harsh chemicals, extreme temperatures, or the need for a near-frictionless surface.

Why Teflon is a Go-To Material for Demanding Roles

The widespread application of machined Teflon, technically known as Polytetrafluoroethylene (PTFE), stems from a core set of elite properties. Understanding these attributes is key to understanding its value.

Unmatched Chemical Inertness

Teflon is famously non-reactive. It can withstand nearly all industrial chemicals, acids, and bases, making it essential for components in chemical processing plants.

This inertness ensures that parts like liners for tanks and pipes do not corrode or contaminate the substances they are in contact with.

Extremely Low Coefficient of Friction

Teflon has one of the lowest friction coefficients of any solid material, often compared to wet ice on wet ice.

This "slipperiness" makes it the perfect choice for self-lubricating bearings, bushings, and wear parts, reducing energy loss and mechanical wear in moving systems.

High-Temperature and Cryogenic Stability

Machined Teflon parts perform reliably across an exceptionally wide temperature range.

They maintain their integrity in high-heat environments and remain durable and flexible even at cryogenic temperatures, a versatility few materials can match.

Excellent Electrical Insulation

Teflon is an outstanding electrical insulator with high dielectric strength.

This property makes it indispensable in the electronics and aerospace industries for insulating high-voltage cables, wires, and sensitive electronic components.

A Cross-Industry Look at Machined Teflon Applications

Because of its versatile properties, you will find machined Teflon components in nearly every advanced industry.

Industrial and Chemical Processing

In harsh industrial settings, Teflon is used for seals, gaskets, and valve components that must resist aggressive chemicals and high pressures without degrading.

It's also machined into liners for pipes and storage tanks to create a non-corrosive barrier.

Aerospace and Automotive

The aerospace industry uses Teflon for electrical insulation, surface protection on spacecraft, and fuel hoses that handle corrosive fuels.

In automotive applications, its low-friction nature is ideal for bearings, seals, and gaskets that improve efficiency and longevity.

Medical and Food Processing

Teflon's biocompatibility and purity mean it can be used inside the human body for implants and surgical instruments.

In food processing, its non-stick surface is perfect for liners, seals, and conveyor belt components that require cleanliness and prevent sticking.

Electronics and Scientific Equipment

The material's insulating properties are vital for creating custom insulators and components for electronics.

In laboratory settings, its chemical resistance makes it ideal for specialty scientific equipment that handles a variety of reactive substances.

Understanding the Trade-offs of Teflon (PTFE)

While its benefits are significant, Teflon is not the ideal solution for every problem. An objective assessment requires acknowledging its limitations.

Relatively Low Mechanical Strength

Compared to metals or other engineering plastics, PTFE is a soft material. It is not suitable for high-load structural applications.

Susceptibility to Creep

Under a constant load, Teflon parts can slowly deform over time, a phenomenon known as "creep." This must be accounted for in component design.

Difficult to Bond

Teflon's non-stick surface makes it very difficult to bond to other materials using conventional adhesives. Special surface treatments are required.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is chemical resistance: Teflon is one of the best choices available for parts exposed to corrosive media.

- If your primary focus is low-friction movement: Its self-lubricating properties make it ideal for bearings, bushings, and sliding components.

- If your primary focus is high-purity or medical use: Teflon's biocompatibility and inertness make it a trusted material for medical and food-grade applications.

- If your primary focus is high-load structural integrity: You should consider other materials, as Teflon's mechanical strength is a known limitation.

Ultimately, choosing machined Teflon means prioritizing its elite chemical, thermal, and frictional properties for applications where performance cannot be compromised.

Summary Table:

| Property | Key Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists corrosive substances | Seals, gaskets, tank liners |

| Low Friction | Self-lubricating, reduces wear | Bearings, bushings, wear parts |

| Temperature Stability | Performs from cryogenic to high heat | Valve components, insulators |

| Electrical Insulation | High dielectric strength | Cable insulation, electronic components |

| Biocompatibility | Safe for medical/food use | Implants, surgical tools, food-grade seals |

Need a high-performance PTFE component that standard parts can't match?

KINTEK specializes in precision machining of Teflon for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with advanced manufacturing to deliver custom solutions—from prototypes to high-volume production—that ensure reliability in harsh chemical, high-temperature, and ultra-clean environments.

Contact KINTEB today to discuss your project requirements and get a quote for custom PTFE parts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance