At their core, PTFE lined valves are specialized components designed to operate in environments where standard valves would quickly fail. Their main applications are in industries that handle highly corrosive, abrasive, or high-purity fluids, including chemical processing, pharmaceuticals, food and beverage, water treatment, and semiconductor manufacturing. The PTFE liner creates a protective, non-reactive barrier between the process fluid and the valve's metal body.

The crucial insight is that PTFE lined valves are not just for specific industries, but for a specific problem: safely controlling aggressive or sensitive fluids that would otherwise corrode, contaminate, or damage standard metal components.

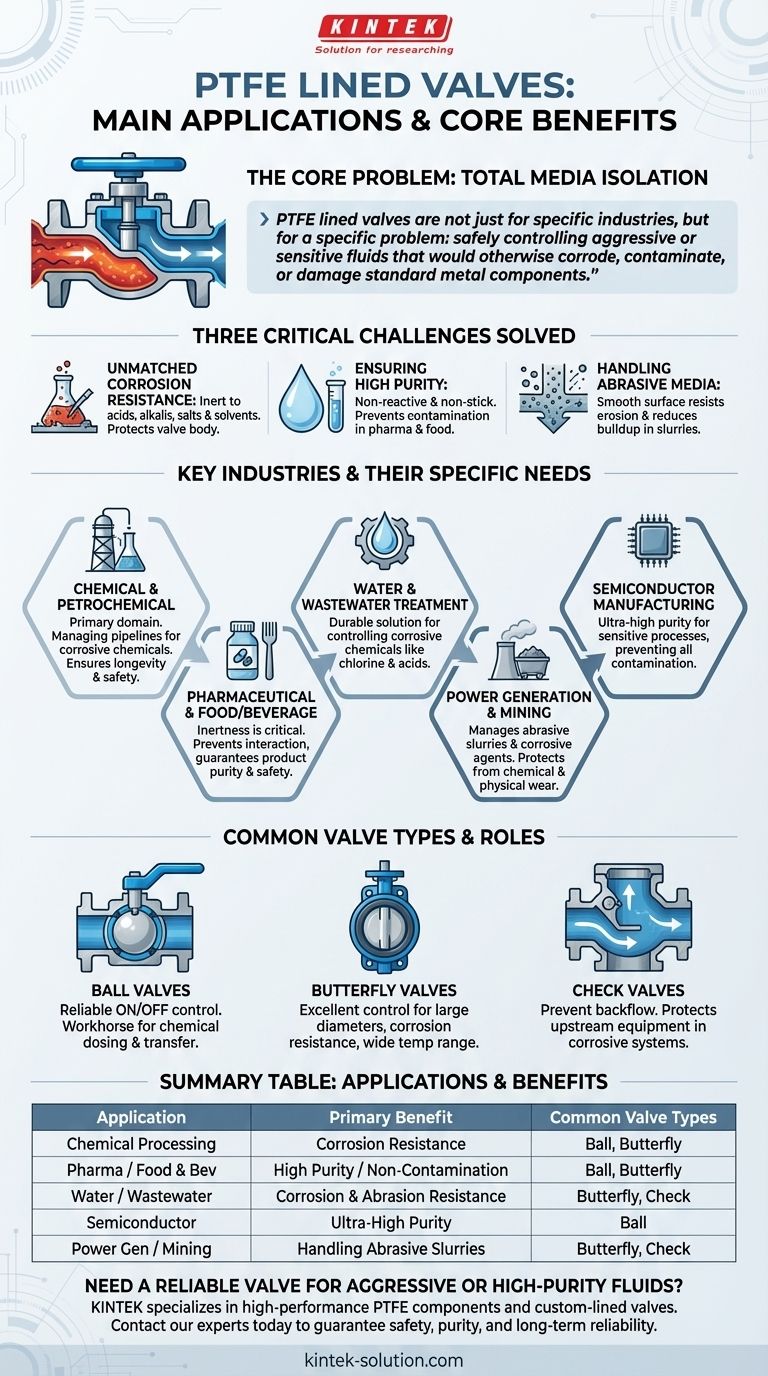

The Core Problem Solved: Total Media Isolation

The fundamental purpose of a PTFE (Polytetrafluoroethylene) lining is to isolate the valve's structural body, typically made of carbon or stainless steel, from the process media. This solves several critical challenges simultaneously.

### Unmatched Corrosion Resistance

PTFE is chemically inert to a vast range of substances. This makes it the ideal choice for handling aggressive media like strong acids, alkalis, salts, and organic solvents that would rapidly degrade most metals. The liner acts as a complete barrier, preventing chemical attacks on the valve body.

### Ensuring High Purity

In industries like pharmaceuticals, food production, and semiconductor manufacturing, preventing contamination is paramount. The non-reactive and non-stick nature of PTFE ensures that the fluid passing through the valve remains pure and is not tainted by leached metals or corrosion byproducts.

### Handling Abrasive Media

For applications involving slurries or fluids with suspended particles, such as in mining or wastewater treatment, the liner protects the metal valve body from erosion. The smooth, low-friction surface of PTFE also helps reduce buildup and ensures smoother operation.

Key Industries and Their Specific Needs

While the principle of media isolation is universal, its application is tailored to the unique demands of different sectors.

### Chemical and Petrochemical Processing

This is the primary domain for PTFE lined valves. They are essential for managing pipelines transporting a wide array of corrosive chemicals, ensuring both the longevity of the equipment and the safety of the operation.

### Pharmaceutical and Food & Beverage

In these highly regulated industries, the inertness of PTFE is critical. It prevents any interaction between the valve and the product, guaranteeing the purity and safety required for consumer products and medications.

### Water and Wastewater Treatment

Treatment facilities use various chemicals like chlorine and acids that are highly corrosive. PTFE lined valves provide a durable and cost-effective solution for controlling these substances without rapid degradation.

### Power Generation and Mining

Power plants often use corrosive chemicals in their water treatment and cooling systems. In mining, these valves are used to manage abrasive slurries and corrosive leaching agents, protecting equipment from both chemical and physical wear.

Common Valve Types and Their Roles

The PTFE lining is applied to various valve designs, each suited for a specific function within a pipeline system.

### Ball Valves

PTFE lined ball valves are primarily used for reliable ON/OFF control. Their simple, robust design combined with the protective liner makes them a workhorse in chemical dosing and transfer lines.

### Butterfly Valves

Offering excellent control for larger pipe diameters, PTFE lined butterfly valves are valued for their corrosion resistance, good sealing capabilities, and wide temperature tolerance (from -100°C to over 200°C).

### Check Valves

These valves are designed for a single purpose: to prevent backflow. In systems handling corrosive chemicals, a PTFE lined check valve ensures fluid flows in only one direction, protecting pumps and other upstream equipment from damage.

Making the Right Choice for Your Goal

Selecting the correct valve depends entirely on the specific challenge you are trying to solve within your system.

- If your primary focus is controlling highly corrosive chemicals: A PTFE lined ball or butterfly valve provides the best defense against chemical attack for ON/OFF or throttling applications.

- If your primary focus is maintaining absolute media purity: The inert, non-leaching properties of a PTFE liner are non-negotiable for pharmaceutical, semiconductor, or food-grade processes.

- If your primary focus is preventing reverse flow in a corrosive line: A PTFE lined check valve is the specific, purpose-built solution to protect your critical equipment.

Ultimately, choosing a PTFE lined valve is a strategic decision to ensure operational safety, product purity, and long-term equipment reliability.

Summary Table:

| Application | Primary Benefit | Common Valve Types |

|---|---|---|

| Chemical Processing | Corrosion Resistance | Ball, Butterfly |

| Pharmaceutical / Food & Beverage | High Purity / Non-Contamination | Ball, Butterfly |

| Water / Wastewater Treatment | Corrosion & Abrasion Resistance | Butterfly, Check |

| Semiconductor Manufacturing | Ultra-High Purity | Ball |

| Power Generation / Mining | Handling Abrasive Slurries | Butterfly, Check |

Need a reliable valve for aggressive or high-purity fluids?

KINTEK specializes in manufacturing high-performance PTFE components, including custom-lined valves, for the semiconductor, medical, laboratory, and industrial sectors. We ensure precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss your application and get a solution that guarantees safety, purity, and long-term reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability