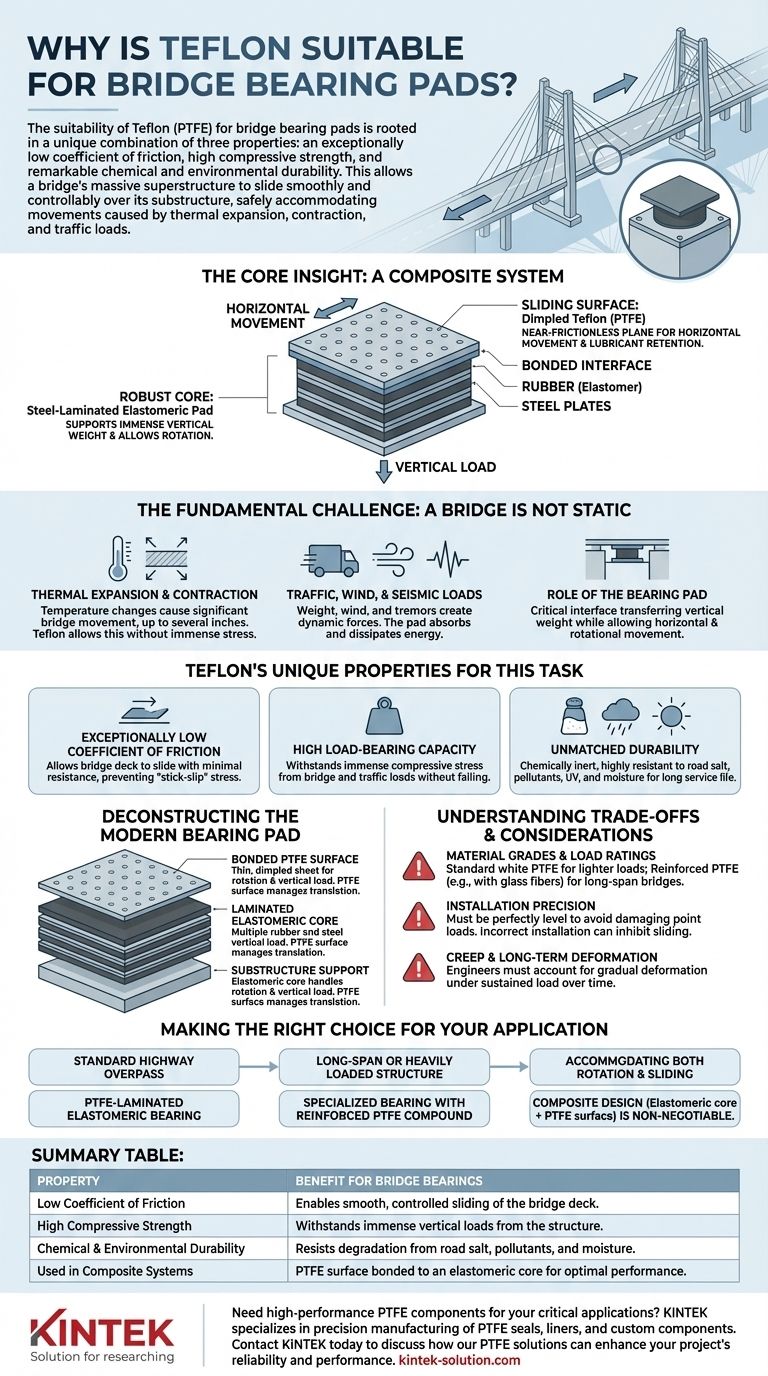

The suitability of Teflon for bridge bearing pads is rooted in a unique combination of three properties: an exceptionally low coefficient of friction, high compressive strength, and remarkable chemical and environmental durability. This allows a bridge's massive superstructure to slide smoothly and controllably over its substructure, safely accommodating movements caused by thermal expansion, contraction, and traffic loads.

The core insight is that Teflon is not used in isolation. Its true value is realized in a composite system where a thin, dimpled Teflon (PTFE) surface is bonded to a robust, steel-laminated elastomeric pad. This design brilliantly separates the two primary functions of a bearing: the elastomeric core supports the immense vertical weight, while the Teflon surface provides a near-frictionless plane for horizontal movement.

The Fundamental Challenge: A Bridge is Not Static

A common misconception is that a bridge is a rigid, immovable object. In reality, it is in a constant state of subtle movement. A bearing pad is the critical interface designed to manage these forces and prevent them from damaging the structure.

Thermal Expansion and Contraction

The most significant movement a bridge experiences is due to temperature change. As materials heat up, they expand; as they cool, they contract. Over the span of a long bridge, this movement can amount to several inches, creating immense stress if not properly accommodated.

Traffic, Wind, and Seismic Loads

Beyond thermal effects, the weight of vehicles, high winds, and potential seismic activity all introduce forces that cause deflection, vibration, and movement. The bearing pad must absorb and dissipate the energy from these dynamic loads.

The Role of the Bearing Pad

The bearing pad sits between the bridge deck (superstructure) and the supporting piers (substructure). Its job is to provide a controlled point of contact that transfers vertical weight while allowing for the necessary horizontal and rotational movements, preventing stress from building up in the concrete and steel.

Teflon's Unique Properties for This Task

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, possesses a specific set of characteristics that makes it almost perfectly suited for the sliding surface of a modern bearing pad.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This allows the bridge deck to slide with minimal resistance across the bearing surface. This smooth, predictable movement is essential for preventing the "stick-slip" phenomenon that can transfer jarring stress into the substructure.

High Load-Bearing Capacity

Despite its slick surface, PTFE is capable of withstanding the immense compressive stress exerted by the weight of the bridge and the traffic it carries. This ensures the material does not fail under the constant vertical load.

Unmatched Durability

Bridge bearings are exposed to harsh conditions, including road salt, pollutants, UV radiation, and constant moisture. Teflon is chemically inert and highly resistant to environmental degradation, ensuring a long and reliable service life with minimal maintenance.

Deconstructing the Modern Bearing Pad

It is crucial to understand that a "Teflon bearing pad" is not a solid block of Teflon. It is a sophisticated composite system where each component has a specialized role.

The Laminated Elastomeric Core

The body of the bearing pad consists of multiple layers of a durable rubber (like natural rubber or chloroprene) vulcanized with reinforcing steel plates. The rubber allows for rotational movement and compression, while the steel plates prevent the rubber from bulging outwards under load, dramatically increasing its vertical load capacity.

The Bonded PTFE Surface

A thin sheet of dimpled PTFE is bonded to the top of the elastomeric core. This sheet acts as the sliding surface. The dimples are engineered to hold a specialized silicone lubricant, which further reduces the initial coefficient of friction and ensures smooth movement from the very first micromovement.

Understanding the Trade-offs and Considerations

While highly effective, the selection and implementation of PTFE bearings require careful engineering consideration to ensure optimal performance.

Material Grades and Load Ratings

Not all PTFE is the same. Standard white PTFE is often used for lighter loads. For heavier and more demanding applications, such as long-span bridges, the PTFE is often reinforced with glass fibers or other materials (such as Fluorogold) to significantly increase its compressive strength and wear resistance.

Installation Precision

The performance of a PTFE bearing is highly dependent on correct installation. The surfaces must be perfectly level and parallel to ensure even load distribution. Any misalignment can create damaging point loads and inhibit the intended sliding motion.

Creep and Long-Term Deformation

Like many polymers, PTFE can be subject to "creep"—a slow, gradual deformation under sustained load over many years. Engineers must account for this material property in their design calculations to ensure the long-term integrity of the bearing system.

Making the Right Choice for Your Application

The specific design of a bearing pad is determined by the unique demands of the bridge structure.

- If your primary focus is a standard highway overpass: A standard PTFE-laminated elastomeric bearing provides a proven, cost-effective solution for managing typical thermal movement and traffic loads.

- If your primary focus is a long-span or heavily loaded structure: A specialized bearing with a reinforced PTFE compound is necessary to handle the extreme vertical forces and accommodate larger horizontal movements.

- If your primary focus is accommodating both rotation and sliding: The composite design is non-negotiable; the elastomeric core handles rotation while the PTFE surface manages translation, ensuring all forces are managed correctly.

By intelligently combining materials, engineers create a component that allows massive structures to breathe, move, and endure for decades.

Summary Table:

| Property | Benefit for Bridge Bearings |

|---|---|

| Low Coefficient of Friction | Enables smooth, controlled sliding of the bridge deck. |

| High Compressive Strength | Withstands immense vertical loads from the structure. |

| Chemical & Environmental Durability | Resists degradation from road salt, pollutants, and moisture. |

| Used in Composite Systems | PTFE surface bonded to an elastomeric core for optimal performance. |

Need high-performance PTFE components for your critical applications?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get durable, chemically resistant parts that meet exact specifications.

Contact KINTEK today to discuss how our PTFE solutions can enhance your project's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments