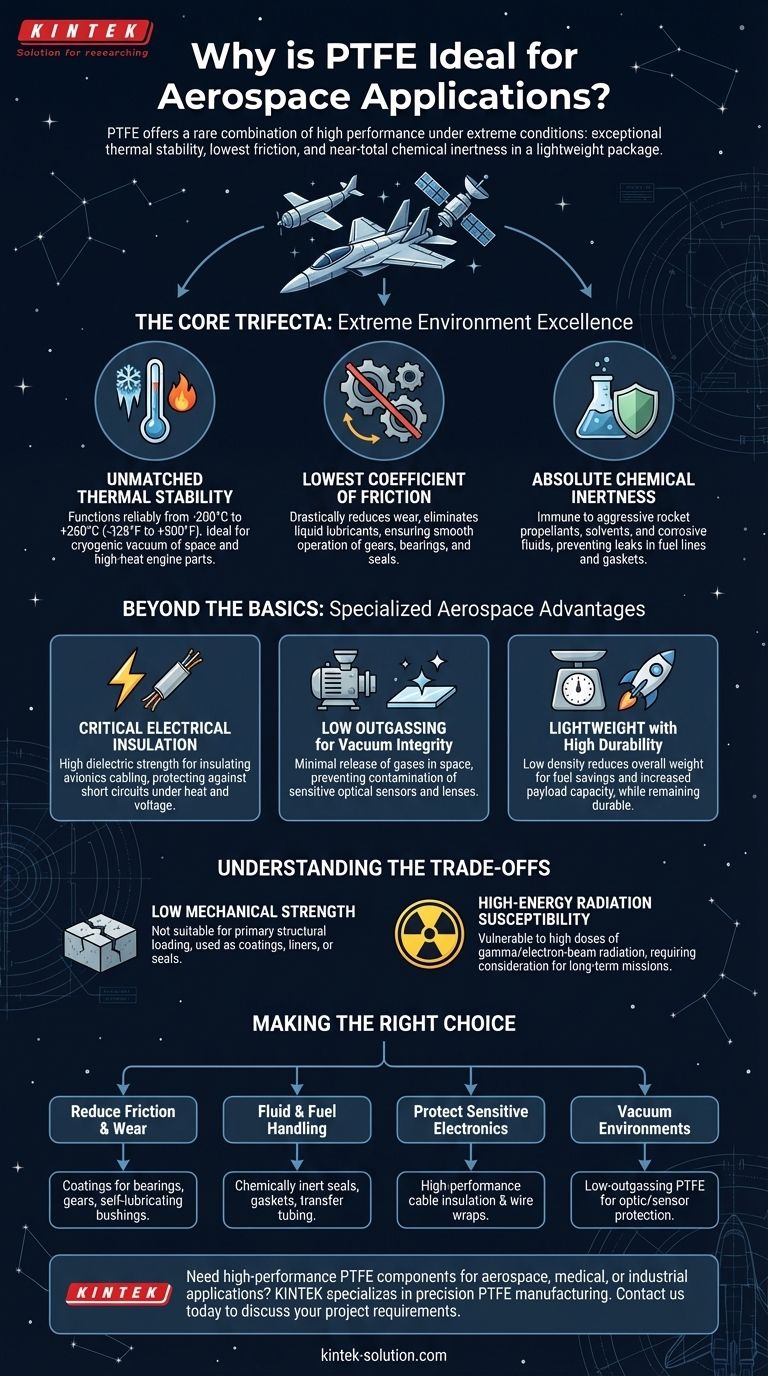

In short, Polytetrafluoroethylene (PTFE) is ideal for aerospace because it offers a rare combination of high performance under extreme conditions. It simultaneously provides exceptional thermal stability from cryogenic temperatures to high heat, the lowest friction of any solid, and near-total chemical inertness, all in a lightweight package.

The core challenge in aerospace is finding materials that don't fail under multiple, contradictory stresses like extreme heat, deep cold, and chemical exposure. PTFE is a standout solution because its unique molecular structure allows it to excel across all of these demanding categories at once.

The Core Trifecta: Why PTFE Excels in Extreme Environments

PTFE's value is not derived from a single characteristic, but from the powerful synergy of three key properties that are rarely found together in one material.

Unmatched Thermal Stability

PTFE maintains its integrity and performance across an astonishingly wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This makes it one of the few materials that can function reliably on components exposed to the frigid vacuum of space and on parts operating in high-temperature engine environments.

The Lowest Coefficient of Friction

Often recognized by its brand name, Teflon, PTFE has one of the lowest coefficients of friction of any known solid material. This creates an exceptionally smooth, "non-stick" surface.

In aerospace, this property is critical for coating gears, bearings, and seals. It drastically reduces wear and eliminates the need for liquid lubricants, which can freeze, boil away, or degrade in the harsh conditions of flight and space.

Absolute Chemical Inertness

PTFE is virtually immune to degradation from almost all industrial chemicals, solvents, and corrosive fluids, including aggressive rocket propellants and hydraulic oils.

This ensures the long-term reliability of fuel lines, seals, and gaskets, preventing leaks and system failures caused by material breakdown.

Beyond the Basics: Specialized Aerospace Advantages

While the core trifecta makes PTFE a contender, several other properties make it a definitive choice for specialized aerospace applications.

Critical Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it an essential material for insulating wires and cabling for critical avionics. It protects sensitive electronic systems from short circuits while also resisting heat and chemical exposure.

Low Outgassing for Vacuum Integrity

In the vacuum of space, some materials release trapped gases in a process called outgassing. These released molecules can contaminate sensitive optical lenses, sensors, and other critical surfaces.

PTFE has exceptionally low outgassing properties, making it a safe and reliable choice for components used in satellites, spacecraft, and other vacuum-exposed systems.

Lightweight with High Durability

Every gram counts in aerospace design. PTFE’s low density helps reduce overall aircraft and spacecraft weight, which translates directly to fuel savings and increased payload capacity.

Despite being lightweight, it offers excellent durability, dimensional stability, and resistance to UV radiation and moisture, ensuring a long service life.

Understanding the Trade-offs

No material is perfect. Acknowledging PTFE's limitations is key to using it effectively.

Relatively Low Mechanical Strength

Compared to metals or high-strength engineering plastics, PTFE is relatively soft and has lower tensile strength. It is not suitable for primary structural load-bearing applications.

This is why it is often used as a coating, liner, or seal rather than as a standalone structural component.

Susceptibility to High-Energy Radiation

While highly resistant to UV light, very high doses of gamma or electron-beam radiation can cause the polymer chains in PTFE to break down, degrading its mechanical properties.

This must be considered for missions with long-duration exposure to high-radiation environments, such as those outside Earth's protective magnetosphere.

Specialized Manufacturing Processes

PTFE has a very high melting point and viscosity, which makes it more difficult to process than common thermoplastics like nylon or polycarbonate.

Manufacturing components often requires specialized techniques like compression molding and sintering, which can influence design complexity and cost.

Making the Right Choice for Your Application

The decision to use PTFE should be based on the specific problem you are trying to solve.

- If your primary focus is reducing friction and wear: Use PTFE for coatings on bearings, gears, and seals, or as a material for self-lubricating bushings.

- If your primary focus is fluid or fuel handling: Use PTFE for chemically inert seals, gaskets, and transfer tubing to ensure system integrity.

- If your primary focus is protecting sensitive electronics: Use PTFE for high-performance cable insulation and wire wraps, especially where thermal stability is also required.

- If your primary focus is components for vacuum environments: Select a low-outgassing grade of PTFE to prevent the contamination of optics and sensors.

Ultimately, PTFE's value lies not in a single property, but in its unique ability to solve multiple, often competing, engineering challenges simultaneously.

Summary Table:

| Key Property | Benefit for Aerospace |

|---|---|

| Thermal Stability | Functions from -200°C to +260°C, ideal for space and engine environments. |

| Low Friction | Reduces wear on bearings and seals, eliminating liquid lubricants. |

| Chemical Inertness | Resists fuels and corrosive fluids, ensuring leak-free systems. |

| Electrical Insulation | Protects avionics from high voltages and heat. |

| Low Outgassing | Prevents contamination in vacuum environments like satellites. |

| Lightweight | Reduces aircraft weight for fuel savings and increased payload. |

Need high-performance PTFE components for aerospace, medical, or industrial applications?

KINTEK specializes in precision PTFE manufacturing—from custom prototypes to high-volume orders. Our seals, liners, and labware are engineered to excel in extreme conditions. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Under what conditions is the coefficient of friction minimized in PTFE slide bearings? Optimize for Low Friction

- What are the installation best practices for PTFE expansion bellows? Ensure Long-Term Reliability and Prevent Failure

- How does PTFE reduce friction wear in piping systems? Prevent Abrasive Damage and System Failure

- How do PTFE valves compare with PFA valves? A Guide to Superior Chemical Resistance & Durability

- What are the key benefits of using PTFE in seals? Achieve Unmatched Reliability in Extreme Conditions

- What is the temperature range for welded PTFE bellow seals? Unlock Extreme Thermal Performance

- What are the steps to create a custom Teflon sheet for a heat press? Boost Your Production Efficiency & Quality

- How do Teflon bearings perform in demanding applications? Superior Performance in Harsh Environments