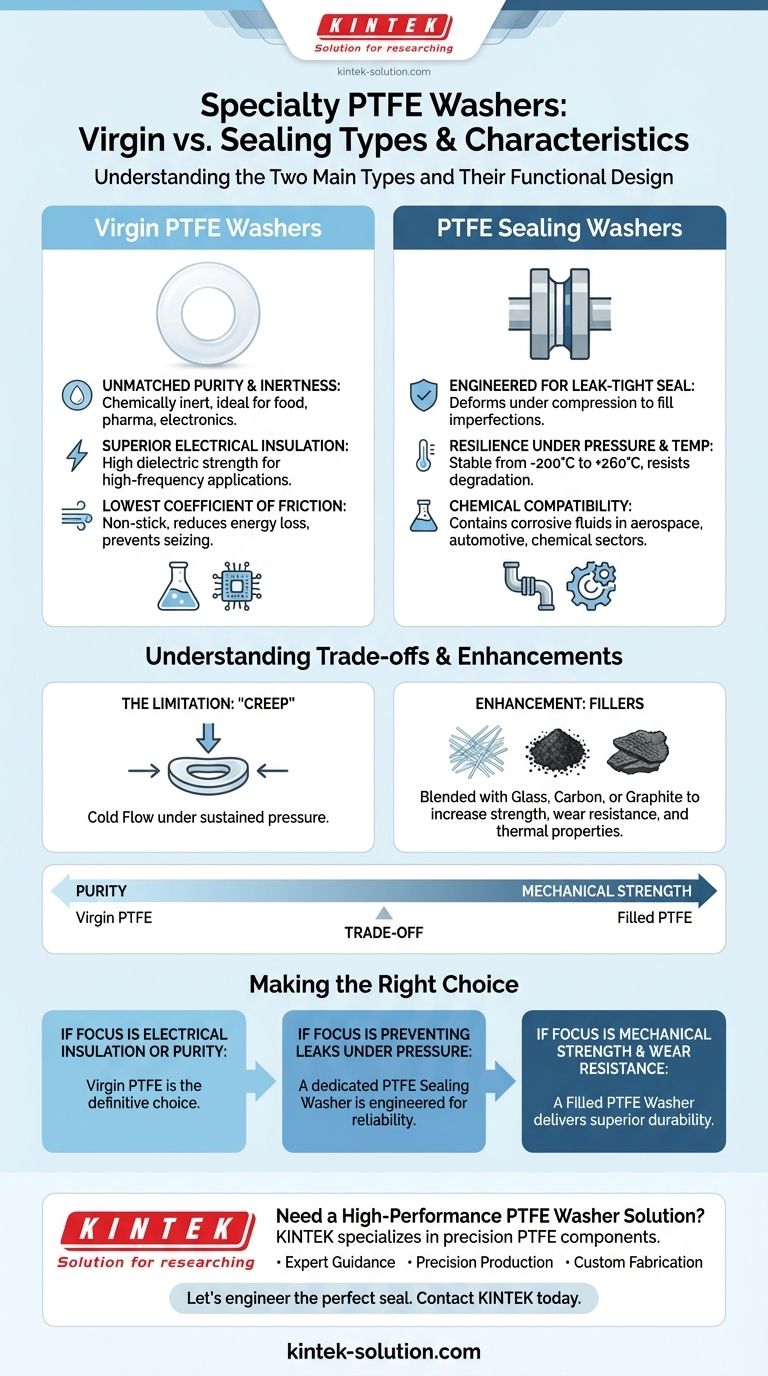

The two main specialty types are virgin PTFE washers and PTFE sealing washers. Virgin PTFE is valued for its exceptional purity, electrical insulation, and low-friction surface, while PTFE sealing washers are specifically engineered to create reliable, leak-tight seals in demanding chemical and thermal environments.

The core distinction is not just between two materials, but between a base material and a functional design. Your choice depends on whether your priority is the inherent purity and low-friction nature of virgin PTFE or the engineered, leak-proof performance of a dedicated sealing washer.

The Foundation: Understanding Virgin PTFE Washers

Virgin PTFE is Polytetrafluoroethylene in its purest form, without any added filler materials. Its properties stem directly from its unique chemical structure, making it the benchmark for certain applications.

Unmatched Purity and Inertness

Virgin PTFE is chemically inert to nearly all industrial chemicals and solvents. This high purity makes it an essential choice for industries like food processing, pharmaceuticals, and sensitive electronics where contamination is not an option.

Superior Electrical Insulation

With exceptionally high dielectric strength, virgin PTFE is one of the best electrical insulators known. It is the go-to material for insulating components in high-frequency electrical applications.

The Lowest Coefficient of Friction

This material has an extremely low coefficient of friction, often compared to wet ice on wet ice. This "non-stick" quality makes it ideal for applications involving sliding parts, such as bearings or low-wear spacers, where it reduces energy loss and prevents seizing.

The Functional Specialist: PTFE Sealing Washers

While often made from PTFE, sealing washers are designed with a primary goal in mind: to prevent leaks. Their shape and potential composition are optimized to create and maintain a durable, leak-tight barrier between two surfaces.

Engineered for a Leak-Tight Seal

The primary function of a sealing washer is to deform slightly under compression, filling microscopic imperfections between mating surfaces. This creates a secure, positive seal that prevents the passage of liquids or gases.

Resilience Under Pressure and Temperature

PTFE's excellent thermal stability (from -200°C to +260°C) allows these sealing washers to maintain their integrity in extreme temperature fluctuations. They resist becoming brittle in the cold or degrading in the heat, ensuring a consistent seal.

Chemical Compatibility

Like virgin PTFE, sealing washers offer outstanding chemical resistance. They are used extensively in chemical processing, aerospace, and automotive industries to contain corrosive fluids and aggressive chemicals without degrading over time.

Understanding the Trade-offs and Enhancements

Choosing the right washer requires looking beyond the two primary categories and understanding how PTFE can be modified to overcome its inherent limitations.

The Limitation of "Creep"

A key characteristic of virgin PTFE is its tendency to "creep" or "cold flow" under sustained pressure. While it deforms to create a seal, it may continue to slowly deform over time, potentially loosening the connection.

The Role of Fillers for Enhanced Performance

To counter creep and enhance other properties, PTFE is often blended with filler materials. This creates a composite material with superior characteristics for specific challenges.

- Glass Fiber-Reinforced: Increases rigidity and wear resistance while reducing creep.

- Carbon-Filled: Improves compressive strength and thermal resistance, providing excellent wear properties.

- Graphite-Filled: Enhances thermal conductivity to help dissipate heat and lowers the coefficient of friction even further.

Purity vs. Mechanical Strength

The primary trade-off is clear: adding fillers improves mechanical properties like strength and creep resistance but compromises the absolute purity and electrical insulating properties of virgin PTFE.

Making the Right Choice for Your Application

Your final decision should be guided by the single most important requirement of your design.

- If your primary focus is electrical insulation or material purity: Virgin PTFE is the definitive choice for its unmatched dielectric properties and inertness.

- If your primary focus is preventing leaks under pressure: A dedicated PTFE sealing washer is specifically engineered to provide a reliable, long-lasting seal.

- If your primary focus is mechanical strength and wear resistance: A filled PTFE washer (e.g., carbon or glass-filled) will deliver superior durability and resistance to creep.

By understanding the distinction between base material properties and application-specific enhancements, you can select the precise PTFE washer that delivers optimal performance for your engineering challenge.

Summary Table:

| Type | Key Characteristics | Primary Applications |

|---|---|---|

| Virgin PTFE Washers | Unmatched purity, superior electrical insulation, low friction, chemically inert | Food processing, pharmaceuticals, sensitive electronics, low-wear spacers |

| PTFE Sealing Washers | Engineered for leak-tight seals, resilient under pressure/temperature, excellent chemical resistance | Chemical processing, aerospace, automotive, containing corrosive fluids |

| Filled PTFE Washers | Enhanced mechanical strength, reduced creep, improved wear/thermal resistance (via glass, carbon, graphite fillers) | Applications requiring durability under sustained load and harsh conditions |

Need a High-Performance PTFE Washer Solution?

Choosing between purity, sealing performance, and mechanical strength is critical. KINTEK specializes in manufacturing precision PTFE components, including custom washers, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

We deliver:

- Expert Guidance: Help you select the right PTFE material (virgin, filled) and design for your specific requirements.

- Precision Production: Ensure consistent quality and performance for every component.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact specifications.

Let's engineer the perfect seal for your project. Contact KINTEK today to discuss your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech