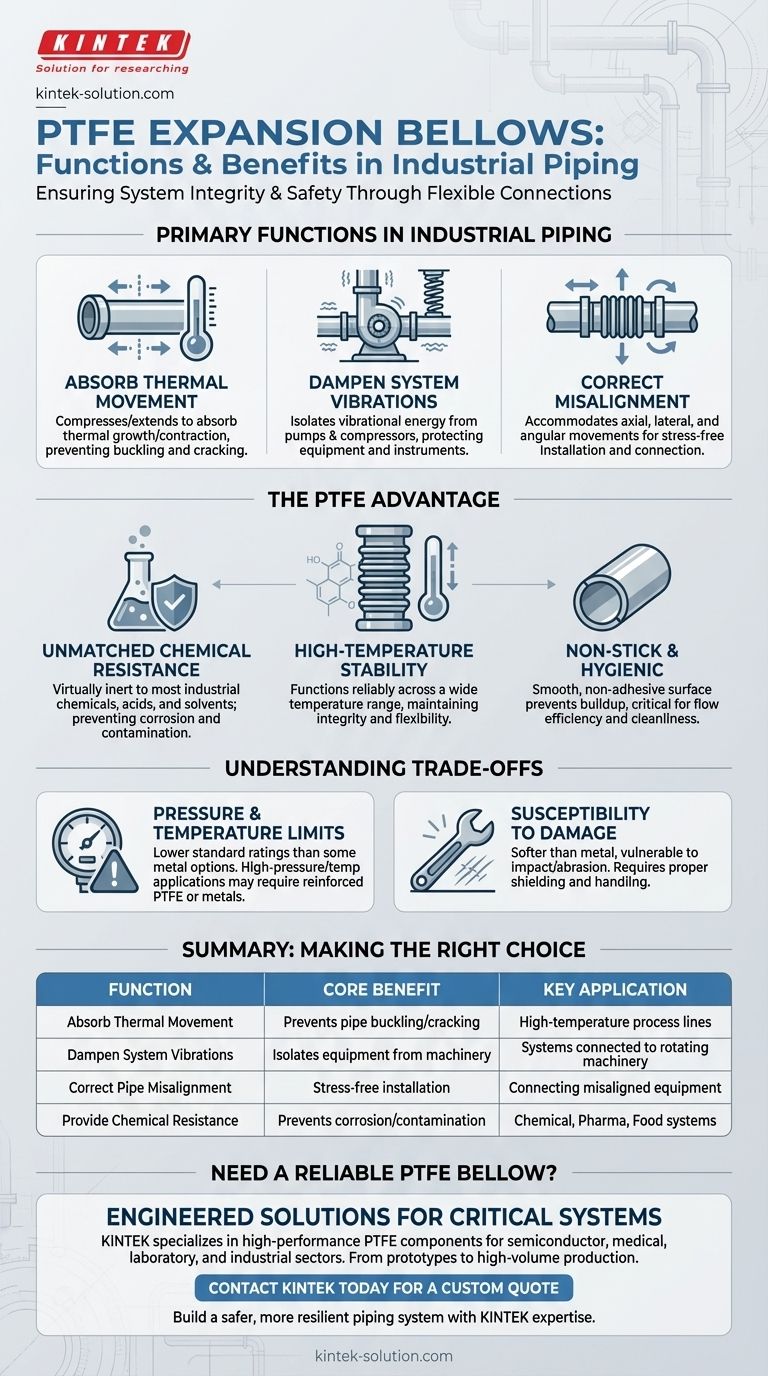

At their core, PTFE expansion bellows serve three primary functions in industrial piping: they absorb movement from thermal expansion and contraction, dampen system vibrations from machinery, and compensate for pipe misalignment. By acting as a flexible, durable joint, they protect the entire system from the stresses that cause cracks, leaks, and catastrophic failures.

The crucial insight is that PTFE expansion bellows are not just flexible connectors; they are specialized engineering components designed to preserve the integrity and safety of a piping system, particularly in environments where chemical resistance and purity are non-negotiable.

The Core Problem: Why Piping Systems Require Flexibility

Rigid piping systems are inherently vulnerable. The dynamic forces of temperature, vibration, and imperfect installation create constant stress that, if left unmanaged, will inevitably lead to damage. Expansion bellows are designed to be the designated point of absorption for these forces.

Counteracting Thermal Expansion and Contraction

Piping materials expand when heated and contract when cooled. In a long, rigid pipe run, this movement can generate immense force.

PTFE bellows compress or extend to absorb this thermal growth, preventing the pipe from buckling, cracking, or placing destructive loads on anchors and connected equipment.

Dampening System Vibrations

Equipment like pumps, compressors, and engines introduce persistent vibrations into a piping system.

These vibrations can fatigue metal, loosen fittings, and damage sensitive instruments over time. PTFE bellows act as a damper, isolating the vibrational energy and protecting the rest of the system.

Correcting Inevitable Misalignment

Achieving perfect, stress-free alignment between two pieces of equipment or pipe sections during installation is practically impossible.

An expansion bellow provides the necessary "give" to connect slightly misaligned components without introducing dangerous residual stress into the system from the outset. Their flexibility accommodates axial (in-and-out), lateral (side-to-side), and angular movements.

The PTFE Advantage: More Than Just a Flexible Joint

While many materials can be used for expansion bellows, Polytetrafluoroethylene (PTFE) offers a unique combination of properties that make it essential for demanding applications. The choice of PTFE is a deliberate engineering decision based on its superior material characteristics.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it the ideal choice for systems in chemical processing, pharmaceutical manufacturing, and food production where corrosion or contamination would be disastrous.

High-Temperature Stability

These bellows function reliably across a wide range of temperatures. They maintain their structural integrity and flexibility during temperature fluctuations that would degrade lesser materials, ensuring consistent performance.

Non-Stick and Hygienic Surfaces

The surface of PTFE is non-adhesive, which prevents materials from building up inside the bellows. This is critical for maintaining flow efficiency and is a necessity in hygienic applications where cleanliness and preventing cross-contamination are paramount.

Understanding the Trade-offs

While highly effective, PTFE expansion bellows are not a universal solution. An objective assessment requires understanding their limitations compared to alternatives like metal bellows.

Pressure and Temperature Limitations

Standard PTFE bellows have lower pressure and temperature ratings than those made from specialized metal alloys like Inconel or stainless steel. High-pressure or high-temperature applications often require reinforced PTFE or a shift to metal alternatives.

Susceptibility to Physical Damage

PTFE is a softer material than metal, making it more vulnerable to external impact or abrasion. Proper shielding and careful handling during installation are necessary to ensure a long service life.

Cost Considerations

Due to the specialized manufacturing process and material properties, high-quality PTFE expansion bellows can represent a higher initial investment than some simple elastomeric or metal options. However, this cost is often justified by reduced maintenance and enhanced system reliability over time.

Making the Right Choice for Your System

Selecting the correct component requires aligning its capabilities with your primary operational goal.

- If your primary focus is chemical compatibility and purity: PTFE is the definitive choice due to its inertness, making it essential for chemical, pharmaceutical, or food-grade systems.

- If your primary focus is vibration isolation for sensitive equipment: The excellent flexibility of PTFE bellows makes them highly effective at dampening damaging vibrations from pumps and motors.

- If your primary focus is extreme pressure or temperature: You must carefully check specifications and consider reinforced PTFE designs or alternative metal bellows that are engineered for those specific conditions.

Ultimately, choosing a PTFE expansion bellow is a strategic decision to build a more resilient, safe, and reliable piping system.

Summary Table:

| Function | Core Benefit | Key Application |

|---|---|---|

| Absorb Thermal Movement | Prevents pipe buckling and cracking from expansion/contraction. | High-temperature process lines. |

| Dampen System Vibrations | Isolates and protects equipment from pump/compressor vibrations. | Systems connected to rotating machinery. |

| Correct Pipe Misalignment | Accommodates axial, lateral, and angular movement for stress-free installation. | Connecting equipment with imperfect alignment. |

| Provide Chemical Resistance | PTFE's inert nature prevents corrosion and contamination. | Chemical processing, pharmaceutical, and food production systems. |

Need a Reliable PTFE Expansion Bellow for Your Critical System?

PTFE expansion bellows are engineered solutions for demanding applications where chemical resistance, purity, and reliability are non-negotiable. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom expansion bellows, seals, liners, and labware.

We serve the semiconductor, medical, laboratory, and specialized industrial sectors, delivering solutions from prototypes to high-volume production runs. Our expertise ensures your piping system is protected from stress, vibration, and failure.

Let us help you build a safer, more resilient system. Contact KINTEB today to discuss your specific requirements and get a custom quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications