The primary factors in selecting a Teflon bearing are the application's mechanical loads, operating speed, temperature range, and chemical environment. A successful selection is not about finding the best overall bearing, but about precisely matching the material properties and design of the bearing to these specific operational demands to ensure reliability and longevity.

Choosing the right Teflon bearing is an exercise in systems thinking. You must move beyond a simple checklist and understand how the load, speed, and environment interact to dictate the ideal material composition and physical design for your specific application.

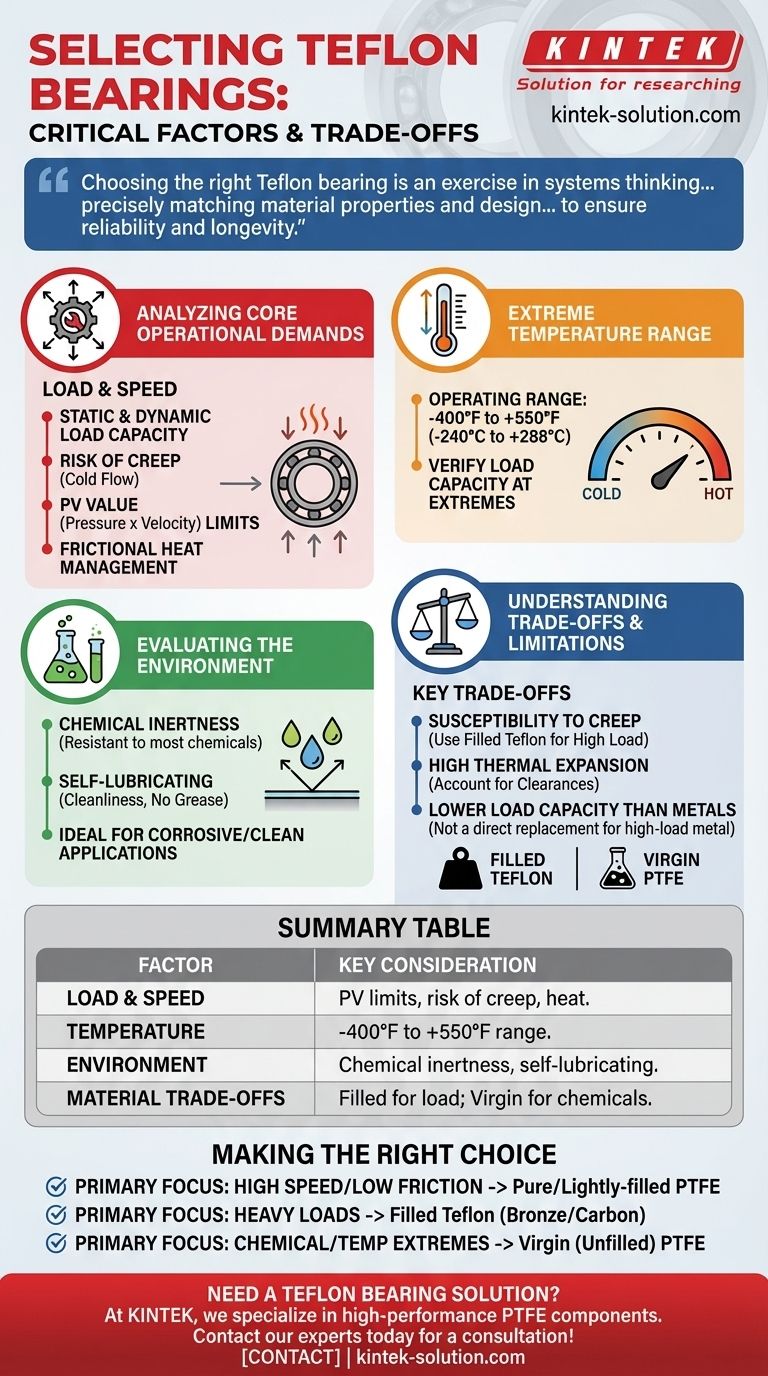

Analyzing Core Operational Demands

The performance of any bearing is defined by the physical forces it must endure. For Teflon bearings, the relationship between load, speed, and temperature is the critical starting point for your analysis.

Load Capacity and Compressive Strength

A bearing must be able to support the applied forces without deforming or failing. You must consider both the static load (when stationary) and the dynamic load (when in motion).

While Teflon offers good compressive strength for a polymer, it is not comparable to metal bearings. Exceeding its load capacity can lead to permanent deformation, a phenomenon known as creep or cold flow.

Speed and Frictional Heat

The maximum operational speed is limited by the bearing's ability to dissipate the frictional heat it generates. This is often expressed as a PV value (Pressure x Velocity).

Exceeding the recommended PV limit will cause the bearing's surface temperature to rise rapidly, leading to accelerated wear and potential failure. Teflon's self-lubricating properties help manage this, but the physical limits must be respected.

Extreme Temperature Range

Teflon is renowned for its exceptional performance across a vast temperature spectrum, typically from -400°F to +550°F (-240°C to +288°C).

However, you must verify the load capacity at your specific operating temperature. Material properties, including strength and wear resistance, can change at the extremes of this range.

Evaluating the Operating Environment

A bearing does not operate in a vacuum. The surrounding conditions can have as much impact on its lifespan as the mechanical loads.

Chemical Exposure

One of Teflon's most significant advantages is its chemical inertness. It is resistant to nearly all industrial chemicals and solvents.

This makes it an ideal choice for applications in corrosive environments, such as chemical processing, food and beverage, or medical devices, where traditional lubricated metal bearings would quickly fail.

Contamination and Cleanliness

Because Teflon bearings are self-lubricating, they do not require external greases or oils that can attract dust, dirt, and other contaminants.

This property is invaluable for applications where cleanliness is paramount, such as in cleanrooms or food processing machinery, and reduces maintenance requirements.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. Acknowledging the inherent trade-offs of Teflon is crucial for avoiding common design pitfalls and ensuring your application is a good fit.

Susceptibility to Creep (Cold Flow)

Under a high, sustained static load, Teflon can slowly deform over time. This is the most significant limitation to consider, especially in high-precision structural applications.

To counteract this, manufacturers often use filled Teflon grades. Adding fillers like glass fiber, carbon, or bronze dramatically improves creep resistance and compressive strength.

High Thermal Expansion

Teflon has a much higher coefficient of thermal expansion than metals. This means it expands and contracts significantly more with temperature changes.

Proper design must account for this. You must ensure that the housing and shaft clearances are sufficient to accommodate this thermal expansion without causing the bearing to seize or become loose.

Lower Load Capacity than Metals

While strong for a polymer, Teflon bearings cannot handle the extreme loads that metallic bearings (like steel or bronze) can.

It is a critical error to attempt a one-to-one replacement of a metal bearing with a Teflon one in a high-load application without a thorough engineering review.

Making the Right Choice for Your Application

Your final decision should be guided by a clear understanding of your primary operational goal.

- If your primary focus is high speed and low friction: A pure or lightly-filled PTFE bearing is often ideal, as it provides the lowest coefficient of friction for smooth, maintenance-free operation.

- If your primary focus is supporting heavy loads: Select a filled Teflon grade, such as bronze-filled or carbon-filled, to gain the necessary compressive strength and resistance to creep.

- If your primary focus is chemical resistance or temperature extremes: Virgin (unfilled) PTFE provides the best chemical inertness and leverages the full, wide operating temperature range of the material.

Ultimately, a successful bearing selection is a direct result of a thorough analysis of your application's specific requirements.

Summary Table:

| Factor | Key Consideration |

|---|---|

| Load & Speed | PV value (Pressure x Velocity) limits; risk of creep and frictional heat. |

| Temperature | Operating range: -400°F to +550°F (-240°C to +288°C). |

| Environment | Chemical inertness; self-lubricating for cleanliness. |

| Material Trade-offs | Filled grades (e.g., bronze) for load; virgin PTFE for chemicals. |

Need a Teflon bearing that precisely fits your application's demands? At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bearings, seals, and liners. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored for the semiconductor, medical, laboratory, and industrial sectors. Let's engineer the perfect bearing for your unique requirements. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability