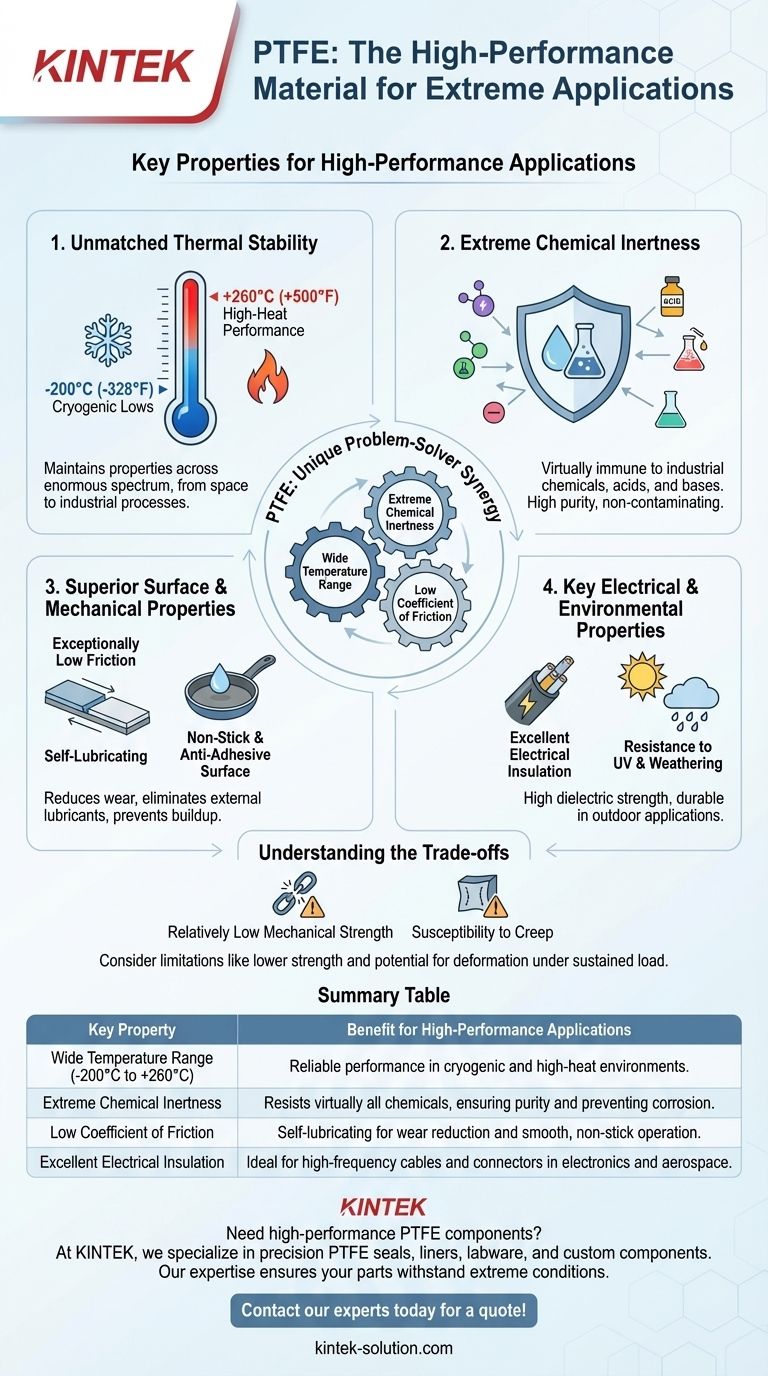

At its core, Polytetrafluoroethylene (PTFE) is specified for high-performance applications because of a unique combination of three defining properties: an exceptionally wide operating temperature range, near-total chemical inertness, and one of the lowest coefficients of friction of any solid material. These characteristics allow it to function reliably in extreme environments where nearly all other plastics would fail.

The critical insight is not that PTFE possesses one exceptional property, but that it combines several extreme characteristics simultaneously. This synergy makes it a unique problem-solver for applications involving aggressive chemicals, high heat, and the need for a low-friction, non-stick surface.

Unmatched Thermal Stability

One of PTFE's most valuable traits is its ability to maintain its properties across an enormous temperature spectrum. This makes it a definitive choice for components that must perform consistently from cryogenic lows to high-heat industrial processes.

High-Temperature Performance

PTFE can operate continuously at temperatures up to +260°C (+500°F) without significant degradation. This high heat resistance ensures mechanical and chemical stability in demanding applications like aerospace components and high-temperature seals.

Low-Temperature Resilience

Equally impressive is its performance at low temperatures. PTFE remains flexible and strong down to -200°C (-328°F), avoiding the brittleness that causes most other polymers to fracture in cryogenic conditions.

Extreme Chemical Inertness

PTFE is renowned for being one of the most non-reactive substances known. This makes it an essential material for handling and containing corrosive fluids that would destroy metals and other plastics.

Resistance to Chemicals and Corrosion

PTFE is virtually immune to attack from the vast majority of industrial chemicals, acids, and bases. Its molecular structure is so stable that it acts as a perfect protective barrier, making it ideal for hose linings, valve components, and gaskets in the chemical processing industry.

High Purity and Non-Contamination

Because it is so inert, PTFE does not leach or contaminate the substances it contacts. This high purity is critical for applications in the food, medical, and semiconductor industries where preventing contamination is non-negotiable.

Superior Surface and Mechanical Properties

PTFE's surface characteristics are fundamental to its use in moving parts and applications where adhesion is undesirable. It is inherently self-lubricating and non-stick.

Exceptionally Low Friction

PTFE has an extremely low coefficient of friction, one of the lowest of any solid material. This allows it to function as a self-lubricating material in bushings, bearings, and seals, reducing wear and eliminating the need for external lubricants.

Non-Stick and Anti-Adhesive Surface

Famously used in non-stick cookware, this property prevents materials from adhering to its surface. This is vital in industrial applications to prevent buildup, ensure smooth operation of parts, and allow for easy cleaning.

Key Electrical and Environmental Properties

Beyond its primary characteristics, PTFE offers other valuable properties that expand its use into electrical and outdoor applications.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with a high dielectric strength and low dissipation factor. This makes it a standard material for insulating high-frequency cables and connectors in the electronics and aerospace industries.

Resistance to UV and Weathering

PTFE is highly resistant to degradation from UV radiation, moisture, and oxidation. It does not become brittle or break down when exposed to the elements, ensuring long-term durability in outdoor applications.

Understanding the Trade-offs

No material is perfect, and a trusted advisor must highlight the limitations. While its primary properties are exceptional, PTFE has notable trade-offs that must be considered during design.

Relatively Low Mechanical Strength

Compared to engineering plastics like PEEK or metals, PTFE has low tensile strength and stiffness. It is not suitable for high-load structural applications without reinforcement (e.g., glass or carbon fiber fillers).

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, PTFE can deform permanently. This phenomenon, known as "creep," must be accounted for when designing components like seals and gaskets that are under constant load.

When to Specify PTFE for Your Application

Choosing the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is aggressive chemical environments: PTFE is an ideal choice for linings, seals, and fluid-handling components that must not corrode or contaminate the process.

- If your primary focus is low-friction, self-lubricating parts: Specify PTFE for bearings, bushings, and sliding plates where minimal wear and smooth, lubricant-free operation are critical.

- If your primary focus is extreme temperature ranges: PTFE is one of the few materials that can perform reliably in both cryogenic and high-heat industrial applications without failing.

- If your primary focus is electrical insulation at high frequencies: Its excellent dielectric properties make PTFE a superior choice for high-performance coaxial cables and connectors.

Ultimately, PTFE is the go-to material for solving engineering challenges in environments too harsh for conventional polymers.

Summary Table:

| Key Property | Benefit for High-Performance Applications |

|---|---|

| Wide Temperature Range (-200°C to +260°C) | Reliable performance in cryogenic and high-heat environments. |

| Extreme Chemical Inertness | Resists virtually all chemicals, ensuring purity and preventing corrosion. |

| Low Coefficient of Friction | Self-lubricating for wear reduction and smooth, non-stick operation. |

| Excellent Electrical Insulation | Ideal for high-frequency cables and connectors in electronics and aerospace. |

Need high-performance PTFE components for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your parts can withstand extreme temperatures, aggressive chemicals, and require minimal maintenance.

We offer custom fabrication from prototypes to high-volume orders, delivering the reliability and performance your application demands.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the temperature range that PTFE can tolerate? Ensure Your Application's Thermal Safety

- Why is PTFE particularly suitable for electrical insulation? Unmatched Dielectric Strength & Resilience

- What is suspension polymerization and what does it produce? A Guide to Granular Polymers for Molding

- How does the grade and type of resin affect the electrical properties of PTFE? Optimize Your Component's Performance

- What is Teflon/PTFE and what are its key properties? Discover the Premier High-Performance Polymer

- What are the disadvantages of Teflon? Understand the Limitations of PTFE

- How does PTFE perform under long-term exposure to weather and UV light? Unmatched Durability for Decades

- What is PTFE and what are its basic properties? The Ultimate Guide to the High-Performance Polymer