At its core, Polytetrafluoroethylene (PTFE) is an almost perfect electrical insulator. Its suitability comes from a rare combination of exceptional dielectric strength, meaning it can withstand very high voltages, and extreme resilience to heat, chemicals, and mechanical stress. This ensures its insulating properties do not degrade even in the most demanding operational environments.

While many materials can insulate electricity, PTFE's true value lies in its unique ability to maintain elite electrical performance under conditions that would cause most other insulators to fail, whether from extreme heat, chemical exposure, or physical stress.

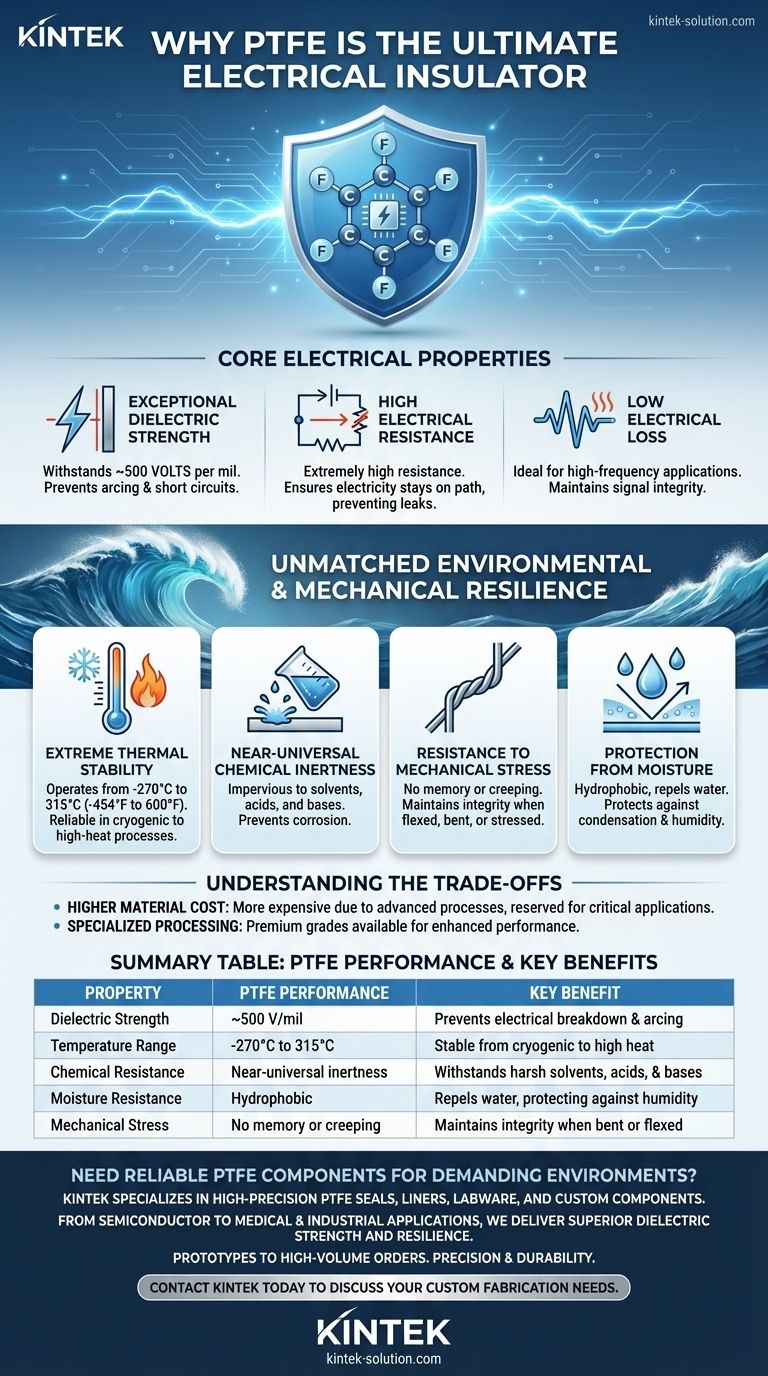

The Core Electrical Properties

PTFE's primary function as an insulator is defined by three key electrical characteristics. These properties work in concert to ensure signals are contained and components are protected.

Exceptional Dielectric Strength

Dielectric strength measures a material's ability to withstand a high voltage before it breaks down and allows current to pass through it.

PTFE can insulate approximately 500 volts per thousandth of an inch of thickness. This makes it an incredibly robust barrier against electrical arcing and short circuits, even in very thin applications.

High Electrical Resistance

Beyond preventing catastrophic breakdown, an insulator must also prevent minor "leaks" of electrical current.

PTFE possesses extremely high resistance, ensuring that electricity stays on its intended path. This is critical for the safe and efficient operation of electronic devices and high-voltage equipment.

Low Electrical Loss

In high-frequency applications, some insulating materials can absorb and dissipate electrical energy as heat, a phenomenon known as dielectric loss.

PTFE has very low electrical loss properties, making it an ideal choice for high-frequency cables and connectors where signal integrity is paramount.

Unmatched Environmental and Mechanical Resilience

What truly sets PTFE apart is its ability to maintain its excellent electrical properties in the face of harsh environmental and physical demands.

Extreme Thermal Stability

Many insulators fail when exposed to high or low temperatures, becoming brittle or losing their structure.

PTFE, however, remains stable and effective across a vast temperature range, from -454°F to 600°F (-270°C to 315°C). This makes it reliable in everything from cryogenic apparatus to high-temperature industrial processes.

Near-Universal Chemical Inertness

The powerful carbon-fluorine bonds in PTFE's molecular structure make it almost completely inert.

It is impervious to nearly all solvents, acids, and bases. This prevents chemical corrosion from degrading the insulation and compromising the underlying conductor.

Resistance to Mechanical Stress

In real-world applications, wires and components are bent, flexed, and stressed.

PTFE's insulation is not subject to memory or creeping. This means that physical manipulation does not weaken or deform the material, ensuring long-lasting protection.

Protection from Moisture

Moisture is a primary cause of electrical failure. PTFE is hydrophobic, meaning it repels water, which protects sensitive electrical components from damage caused by condensation or environmental humidity.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's performance is exceptional, it comes with practical considerations that are important for any technical evaluation.

Higher Material Cost

The advanced chemical processes required to produce PTFE make it more expensive than many standard insulating polymers. Its use is typically reserved for applications where its unique properties are a necessity.

Specialized Processing

For applications requiring even greater insulation or specific properties, specialized grades of PTFE are available. These materials offer enhanced performance but come at an even higher premium.

Making the Right Choice for Your Application

Selecting an insulator requires balancing performance requirements with project constraints.

- If your primary focus is high-voltage performance in a stable environment: PTFE is an excellent choice, but more cost-effective insulators might suffice if extreme chemical or thermal stress is not a factor.

- If your application involves extreme temperatures, harsh chemicals, or frequent flexing: PTFE's unique combination of resilience and electrical integrity is nearly unparalleled and often justifies the investment.

- If you are working on a cost-sensitive, high-volume project with benign conditions: The premium cost of PTFE may be unnecessary, and other polymers could provide adequate performance more economically.

Ultimately, selecting PTFE is a decision to invest in long-term reliability where electrical failure is not an option.

Summary Table:

| Property | PTFE Performance | Key Benefit |

|---|---|---|

| Dielectric Strength | ~500 V/mil | Prevents electrical breakdown and arcing |

| Temperature Range | -270°C to 315°C | Stable performance from cryogenic to high heat |

| Chemical Resistance | Near-universal inertness | Withstands harsh solvents, acids, and bases |

| Moisture Resistance | Hydrophobic | Repels water, protecting against humidity |

| Mechanical Stress | No memory or creeping | Maintains integrity when bent or flexed |

Need reliable PTFE components that won't fail under pressure?

At KINTEK, we specialize in manufacturing high-precision PTFE seals, liners, labware, and custom components. Our expertise ensures your electrical insulation solutions deliver superior dielectric strength and unmatched resilience in the most demanding environments—from semiconductor and medical equipment to specialized industrial applications.

We handle everything from prototypes to high-volume orders, prioritizing precision and durability. Let us provide the reliable PTFE insulation your project requires.

Contact KINTEK today to discuss your custom fabrication needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the tensile strength range of PTFE? Understanding Its Mechanical Limits for Your Design

- What are the primary industrial sectors that utilize PTFE materials? Unlock Performance in Harsh Environments

- How does PTFE compare to Polyethylene (PE) in terms of chemical and temperature resistance? Choose the Right Polymer for Extreme Conditions

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- How does Teflon perform in terms of chemical resistance? Discover the Ultimate Inert Material

- Why is PTFE approved for medical implants? Leveraging Biocompatibility for Medical Devices

- What are the environmental and safety considerations for Teflon and UHMW? Ensure Safe Material Selection

- What are some other types of fillers used in PTFE? Enhance Performance for Demanding Applications