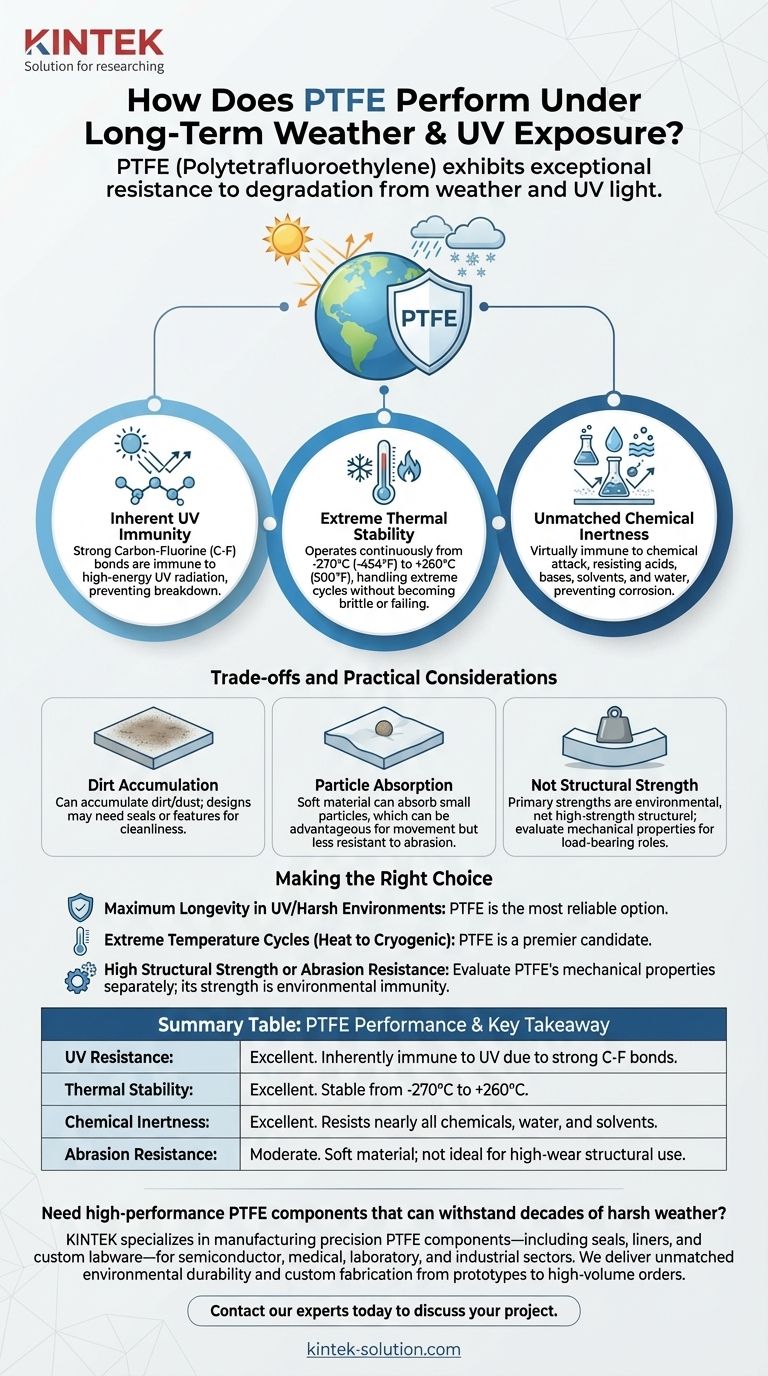

Under long-term exposure, Polytetrafluoroethylene (PTFE) exhibits exceptional resistance to degradation from weather and UV light. Its unique molecular structure, built on powerful carbon-fluorine bonds, is inherently immune to the high-energy radiation from the sun. This makes it one of the most durable polymers for outdoor applications, maintaining its integrity for decades where other materials would fail.

The core reason for PTFE's unmatched environmental durability is not a single feature, but a combination of three properties: near-total immunity to UV radiation, extreme thermal stability across a vast temperature range, and virtual inertness to chemical attack.

Why PTFE Excels in Outdoor Environments

To understand PTFE's performance, we must look beyond a single property and see how its characteristics work together to resist the combined assault of weathering.

Inherent UV Immunity

The primary cause of degradation in most plastics is ultraviolet (UV) radiation, which breaks down their chemical bonds.

PTFE is fundamentally different. The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry. UV radiation lacks the energy to break this bond, meaning the material simply does not degrade from sun exposure.

This property is why PTFE is specified for critical applications like aerospace components and long-lasting architectural fabrics.

Extreme Thermal Stability

Weathering isn't just about sun; it's also about extreme temperature cycles. PTFE performs reliably across an incredibly wide thermal range.

It maintains its properties during continuous operation at temperatures as high as 260°C (500°F). This far exceeds any heat generated by solar exposure.

Simultaneously, it retains its flexibility and avoids becoming brittle at cryogenic temperatures as low as -270°C (-454°F), ensuring it will not crack or fail during deep freezes.

Unmatched Chemical Inertness

An environment's weather includes rain, humidity, salt spray, and atmospheric pollutants, all of which can be corrosive.

PTFE is virtually immune to chemical attack. It resists nearly all acids, bases, solvents, and water. This chemical inertness prevents the slow degradation that plagues other materials in moist or polluted environments.

Understanding the Trade-offs and Practical Considerations

While its environmental resistance is unparalleled, making an informed decision requires understanding its specific physical characteristics.

Susceptibility to Dirt Accumulation

PTFE's surface, while non-reactive, can accumulate dust and dirt over time.

For applications where cleanliness is critical for performance or aesthetics, designs may incorporate seals or features that protect the PTFE surface from buildup.

Particle Absorption

PTFE is a relatively soft material. In applications with moving parts, it has the ability to absorb small, lodged particles.

This can be an advantage, preventing a foreign particle from hindering movement. However, it also means the material is not as resistant to abrasion or cutting as harder plastics.

Focus on Environmental, Not Structural, Strength

PTFE's primary strengths are its thermal, chemical, and UV resistance. It is not an inherently high-strength structural material.

While perfect for seals, liners, coatings, or non-load-bearing components, its selection for a structural role must be carefully evaluated for mechanical properties like tensile strength and compressive resistance under load.

Making the Right Choice for Your Goal

Selecting PTFE should be a deliberate choice based on its unique profile. Consider your primary objective to determine if it is the optimal material.

- If your primary focus is maximum longevity in a UV-intense and chemically harsh environment: PTFE is arguably the most reliable and stable polymer available.

- If your application involves extreme temperature cycles from high heat to cryogenic cold: PTFE's stability across this vast thermal range makes it a premier candidate.

- If your project requires high structural strength or abrasion resistance: You must evaluate PTFE's mechanical properties separately, as its key advantages lie in environmental immunity, not physical toughness.

By understanding both its profound strengths and its specific limitations, you can confidently leverage PTFE in the most demanding environments.

Summary Table:

| Property | PTFE Performance | Key Takeaway |

|---|---|---|

| UV Resistance | Excellent | Inherently immune to UV degradation due to strong C-F bonds. |

| Thermal Stability | Excellent | Stable from -270°C to +260°C, handling extreme temperature cycles. |

| Chemical Inertness | Excellent | Resists nearly all acids, bases, solvents, and water. |

| Abrasion Resistance | Moderate | Softer material; not ideal for high-wear, structural applications. |

Need high-performance PTFE components that can withstand decades of harsh weather?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We deliver unmatched environmental durability and custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can ensure the long-term reliability of your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is reprocessed PTFE? A Cost-Effective Alternative for Non-Critical Applications

- How does Teflon's electrical insulation property benefit its applications? Achieve Unmatched Reliability in Extreme Conditions

- How do Nylon and PTFE compare in terms of friction and wear resistance? Choose the Right Polymer for Your Application

- What gives PTFE its non-stick properties? The Science Behind Its Slippery Surface

- What is PTFE and what are its key attributes? The Ultimate Guide to Its Properties & Uses

- What is the role of valves in industrial piping systems? Ensure Safety, Control, and Efficiency

- What makes PTFE chemically stable? Discover the Science Behind Its Unmatched Inertness

- What are the key properties of PTFE? Unlocking Superior Performance for Demanding Applications