In short, Teflon is the brand name for Polytetrafluoroethylene (PTFE). It is a high-performance synthetic fluoropolymer prized for an extraordinary combination of properties: it is extremely non-stick, highly resistant to nearly all chemicals, and remains stable across a vast range of temperatures. This unique trio of characteristics makes it one of the most versatile and valuable materials in modern engineering.

The true value of PTFE lies not in a single attribute, but in its unique ability to simultaneously withstand extreme heat, resist aggressive chemicals, and provide an incredibly low-friction surface where other materials would quickly fail.

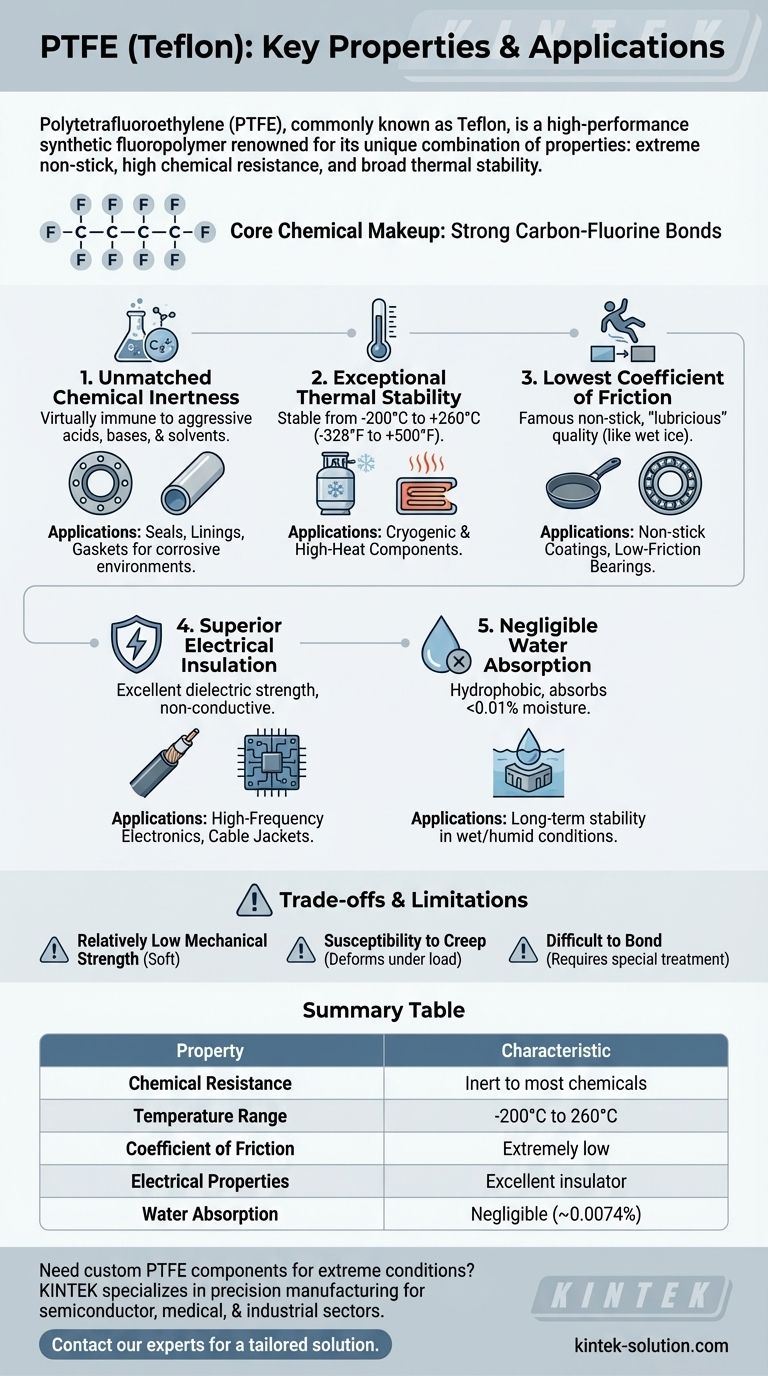

The Core Chemical Makeup of PTFE

A Synthetic Fluoropolymer

Polytetrafluoroethylene is a fluoropolymer, a type of plastic where the molecular backbone is a chain of carbon atoms completely surrounded by fluorine atoms.

The carbon-fluorine bond is exceptionally strong and stable. This powerful bond is the fundamental reason for PTFE's signature properties of chemical inertness and non-reactivity.

Deconstructing the Key Properties of PTFE

Unmatched Chemical Inertness

PTFE is one of the most non-reactive materials known. It is virtually immune to degradation from aggressive acids, bases, and solvents.

This makes it an essential material for seals, linings, and gaskets in chemical processing, laboratory equipment, and industrial pipelines where corrosive substances are common.

Exceptional Thermal Stability

PTFE performs reliably across an immense temperature range, remaining stable from approximately -200°C (-328°F) up to 260°C (500°F).

While its official melting point is around 325°C (617°F), it maintains its structural integrity and core properties well below that, ensuring performance in both cryogenic and high-heat applications.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice. This is the source of its famous non-stick or "lubricious" quality.

This property is critical for applications like non-stick cookware, low-friction bearings, and self-lubricating components where smooth, effortless movement is required.

Superior Electrical Insulation

As a material, PTFE does not conduct electricity and possesses a very high dielectric strength.

This makes it an excellent insulator for high-frequency electronics, cable jackets, and connectors, especially in demanding environments where temperature and chemical resistance are also needed.

Negligible Water Absorption

PTFE is also hydrophobic, meaning it repels water and absorbs an extremely low amount of moisture (around 0.0074%).

This resistance to water absorption contributes to its excellent long-term stability and consistent performance, even when exposed to the elements or submerged.

Understanding the Trade-offs and Limitations

Relatively Low Mechanical Strength

While durable, PTFE is a relatively soft material (a Shore D hardness of around 57). It is not suitable for high-load structural applications where materials like steel or reinforced composites excel.

Susceptibility to Creep

Under a sustained mechanical load, PTFE can slowly deform over time, a phenomenon known as "creep." This must be accounted for in the design of components like seals and bearings.

Difficult to Bond

The same non-stick properties that make PTFE so useful also make it very difficult to bond to other surfaces using conventional adhesives. Specialized surface treatments are often required to achieve a strong bond.

Making the Right Choice for Your Goal

- If your primary focus is corrosion resistance: Specify PTFE for seals, gaskets, and vessel linings in aggressive chemical environments.

- If your primary focus is reducing friction: Use PTFE for non-stick coatings, slide plates, or self-lubricating bearings and bushings.

- If your primary focus is high-frequency electrical insulation: Choose PTFE for wiring, connectors, and circuit board substrates where signal integrity is critical.

- If your primary focus is performance at extreme temperatures: Rely on PTFE for components that must function reliably in both cryogenic and high-heat conditions.

Ultimately, PTFE is a premier problem-solving material engineered to maintain stability and performance in environments that cause most other materials to degrade.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Chemical Resistance | Inert to nearly all acids, bases, and solvents |

| Temperature Range | Stable from -200°C to 260°C (-328°F to 500°F) |

| Coefficient of Friction | One of the lowest of any solid material |

| Electrical Properties | Excellent high-frequency insulator |

| Water Absorption | Extremely low (approx. 0.0074%) |

Need a custom PTFE component that thrives in extreme conditions?

KINTEK specializes in precision manufacturing of PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. We combine material expertise with custom fabrication capabilities—from prototypes to high-volume production—to deliver components that ensure reliability, chemical inertness, and non-stick performance where it matters most.

Contact our experts today to discuss your specific application requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is notable about the coefficient of friction of PTFE? Achieve Unmatched Low-Friction Performance

- How does PTFE compare to High-Density Polyethylene (HDPE)? A Guide to Extreme Performance vs. Cost-Effectiveness

- What are the key qualities of PTFE material? Unlock Extreme Chemical, Thermal & Electrical Resistance

- What are the general characteristics of PTFE? Master Extreme Performance with This High-Performance Polymer

- What is the chemical composition and structure of PTFE? Unlocking the Secrets of Teflon's Power

- What are the challenges in processing PTFE? Overcoming High Melt Viscosity and Machining Difficulties

- What are the properties of pure PTFE material? Unlock Superior Chemical & Thermal Performance

- What is the coefficient of friction (COF) and why is it important? Master Efficiency, Longevity, and Control