In short, the grade and type of PTFE resin fundamentally determine its electrical performance, with unfilled, virgin PTFE offering the purest and most exceptional insulating properties. The introduction of any filler material to create different grades will inevitably alter, and typically degrade, these inherent electrical characteristics in exchange for enhanced mechanical or thermal properties.

While virgin PTFE provides unparalleled electrical insulation due to its molecular structure, filled grades trade some of this elite performance for improved mechanical strength or thermal conductivity. The choice always hinges on the primary demand of your application.

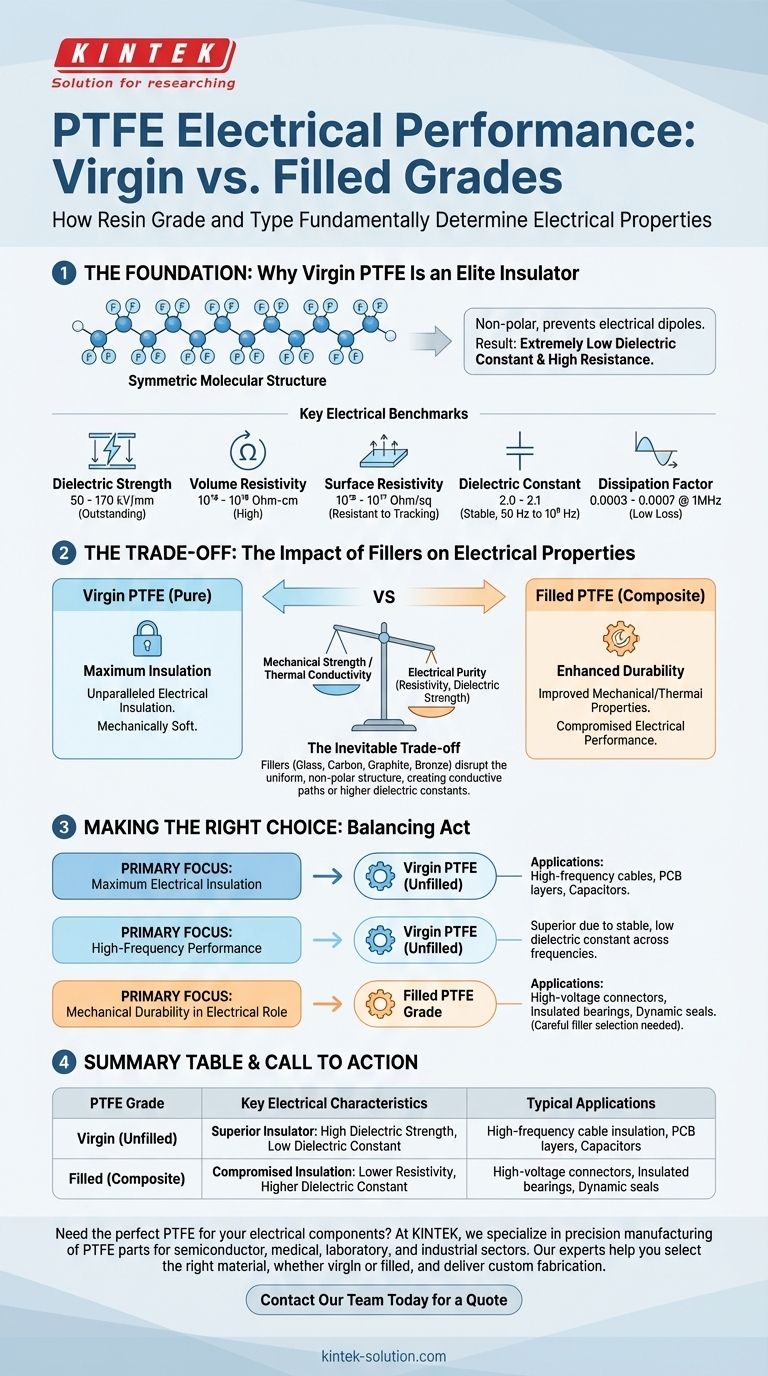

The Foundation: Why Virgin PTFE Is an Elite Insulator

To understand how different grades affect performance, we must first establish the baseline. Unfilled, virgin Polytetrafluoroethylene (PTFE) is one of the best electrical insulators known, a property rooted in its unique molecular structure.

The Role of Molecular Symmetry

The exceptional insulating properties of PTFE begin with its macromolecules. These long-chain molecules have a highly symmetric and uniform structure.

This symmetry means the polymer is non-polar, preventing electrical dipoles from forming easily. This is the core reason for its extremely low dielectric constant and high resistance.

Key Electrical Benchmarks

Virgin PTFE is defined by its outstanding and stable electrical values. It consistently delivers elite performance across several key metrics.

- Dielectric Strength: 50 - 170 kV/mm

- Volume Resistivity: 10¹⁸ - 10¹⁹ Ohm-cm

- Surface Resistivity: 10¹⁶ - 10¹⁷ Ohm/sq

- Dielectric Constant: 2.0 - 2.1 (stable from 50 Hz to 10⁹ Hz)

- Dissipation Factor: 0.0003 - 0.0007 @ 1MHz

These properties remain remarkably stable even when subjected to high voltages and a wide range of frequencies, making PTFE ideal for high-performance electronics.

Resistance to Environmental Factors

PTFE's chemical inertness and low surface tension contribute significantly to its reliability as an insulator.

It is highly water-repellent (hydrophobic), which prevents the formation of conductive moisture paths on its surface. This quality, combined with its high surface resistivity, makes it very resistant to electrical tracking.

The Impact of Fillers on Electrical Properties

While virgin PTFE is an electrical champion, it is mechanically soft. Fillers are added to create composite grades with superior wear resistance, creep strength, or thermal conductivity. This enhancement, however, comes at an electrical cost.

Why Add Fillers?

Fillers like glass fiber, carbon, graphite, or bronze are blended with PTFE resin to create materials tailored for specific mechanical challenges.

These compounds are essential for components like seals, bearings, and structural parts that must endure physical stress while providing some degree of insulation.

The Inevitable Electrical Trade-off

The moment a filler is introduced into the pure PTFE matrix, the exceptional electrical properties are compromised.

The filler particles disrupt the uniform, non-polar structure of the PTFE. Since virtually all fillers have electrical properties inferior to pure PTFE, they degrade the overall performance of the composite material.

How Fillers Modify Specific Properties

The degree and nature of the electrical degradation depend entirely on the type and concentration of the filler used.

For example, adding conductive fillers like carbon or graphite will drastically reduce the material's resistivity. Other fillers, like glass, may have a higher dielectric constant than PTFE, which will raise the overall dielectric constant of the composite.

Understanding the Trade-offs

Choosing a PTFE grade is a balancing act between electrical purity and mechanical robustness. There is no single "best" grade; there is only the best grade for a specific set of operational demands.

Virgin PTFE: Maximum Insulation

Choose unfilled, virgin PTFE when the absolute highest electrical performance is the non-negotiable priority.

This is the standard for high-frequency cable insulation, high-performance capacitor dielectrics, and insulating layers on printed circuit boards where mechanical stress is minimal.

Filled PTFE: Enhanced Durability

Choose a filled PTFE grade when a component must withstand mechanical loads but still requires good electrical insulation.

This is common for electromechanical parts like high-voltage connectors, insulated bearings, or dynamic seals. The key is to select a filler that provides the needed mechanical boost while having the least negative impact on the most critical electrical property for that application.

Making the Right Choice for Your Application

Your selection must be guided by a clear understanding of the primary function your component will serve.

- If your primary focus is maximum electrical insulation: Unfilled, virgin PTFE is the only appropriate choice, as it offers the highest dielectric strength and resistivity.

- If your primary focus is high-frequency performance: Virgin PTFE is superior due to its exceptionally low and stable dielectric constant across a vast frequency spectrum.

- If your primary focus is mechanical durability in an electrical role: A filled PTFE is necessary, but you must carefully select a grade where the filler minimally degrades the specific electrical characteristic most critical to your design.

Ultimately, selecting the correct PTFE grade requires a clear analysis of whether your application's primary challenge is electrical, mechanical, or a calculated balance of both.

Summary Table:

| PTFE Grade | Key Electrical Characteristics | Typical Applications |

|---|---|---|

| Virgin (Unfilled) | Superior insulator: High dielectric strength (50-170 kV/mm), Low dielectric constant (2.0-2.1) | High-frequency cable insulation, PCB layers, capacitors |

| Filled (Composite) | Compromised insulation: Lower resistivity, Higher dielectric constant | High-voltage connectors, insulated bearings, dynamic seals |

Need the perfect PTFE for your electrical components?

At KINTEK, we specialize in precision manufacturing of PTFE parts for the semiconductor, medical, laboratory, and industrial sectors. Whether your priority is ultimate electrical insulation from virgin PTFE or the enhanced mechanical strength of a filled grade, our experts can help you select the right material and deliver custom fabrication from prototypes to high-volume orders.

Contact our team today to discuss your project's requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss