The commercial value of Polytetrafluoroethylene (PTFE) is rooted in a rare combination of three core properties: its near-total chemical inertness, an extremely low coefficient of friction, and exceptional stability across a wide range of temperatures. These characteristics allow it to perform reliably in demanding chemical, mechanical, and electrical applications where most other polymers would quickly degrade and fail.

PTFE is not just a single-purpose material; it is a versatile problem-solver. Its value comes from its unique ability to simultaneously resist harsh chemicals, reduce friction, and withstand extreme temperatures, making it indispensable in industries from aerospace to medicine.

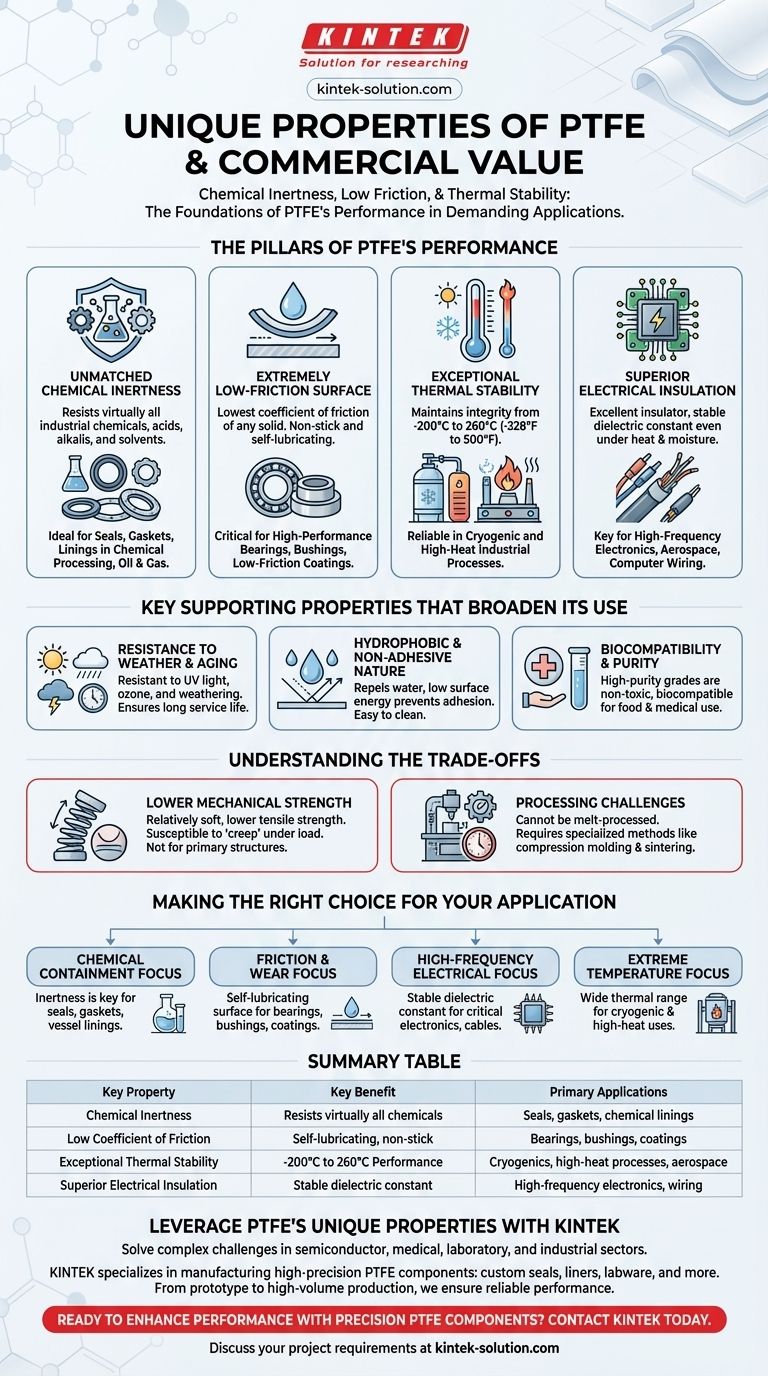

The Pillars of PTFE's Performance

PTFE's unique molecular structure, a long chain of carbon atoms completely shielded by fluorine atoms, is the source of its remarkable properties. This robust carbon-fluorine bond is one of the strongest in organic chemistry.

Unmatched Chemical Inertness

PTFE is resistant to virtually all industrial chemicals, including concentrated acids, alkalis, corrosive agents, and organic solvents. It is almost completely insoluble.

This property makes it the gold standard for applications involving aggressive substances, such as seals, gaskets, and linings for pipes and reaction vessels in the chemical processing and oil and gas industries.

An Extremely Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice. This gives it exceptional non-stick and self-lubricating characteristics.

This is the property behind its most famous application in non-stick cookware (Teflon), but it is also critical for industrial uses like high-performance bearings, bushings, and low-friction coatings where smooth movement is essential.

Exceptional Thermal Stability

The material maintains its integrity and properties across an incredibly broad temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

This stability allows PTFE to be used in cryogenic applications as well as in high-heat industrial processes without becoming brittle or melting, a range that few other polymers can tolerate.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very low dielectric constant. Crucially, these insulating properties remain stable even when exposed to high heat and moisture.

This reliability makes it a key material for high-frequency electronics and for insulating high-performance wiring and cables used in demanding aerospace and computer applications.

Key Supporting Properties That Broaden Its Use

Beyond the core pillars, several other characteristics make PTFE uniquely suited for a wide array of specialized applications.

Resistance to Weather and Aging

PTFE is highly resistant to degradation from UV light, ozone, and general weathering. It does not become brittle or break down when exposed to the elements over long periods.

This durability ensures a long service life for components used in outdoor or harsh environmental conditions.

Hydrophobic and Non-Adhesive Nature

The material is intensely hydrophobic, meaning it repels water and absorbs almost none. Its surface energy is so low that very few substances will permanently adhere to it.

This makes it easy to clean and ideal for use in medical tubing, food processing equipment, and any application where contamination is a concern.

Biocompatibility and Purity

High-purity grades of PTFE are available that are non-toxic and biocompatible, making them safe for both food contact and medical applications.

This has enabled its use in surgical implants, medical devices, and machinery for food and pharmaceutical manufacturing.

Understanding the Trade-offs

No material is perfect, and PTFE is no exception. While its unique properties make it an elite performer, it has limitations that are important to understand.

Lower Mechanical Strength

Compared to high-strength engineering plastics, PTFE is relatively soft and has lower tensile strength. It can be susceptible to "creep," or deformation under sustained load.

For this reason, it is not typically used for primary structural components. Its strength lies in its surface properties and resistance, not its load-bearing capacity.

Processing Challenges

PTFE cannot be processed using conventional melt-processing techniques like injection molding that are common for other thermoplastics.

It typically requires more specialized and often slower methods like compression molding and sintering, which can affect manufacturing costs and design complexity.

Making the Right Choice for Your Application

Selecting PTFE is about leveraging its unparalleled strengths for specific, challenging problems.

- If your primary focus is chemical containment: PTFE's near-total chemical inertness makes it the default choice for seals, gaskets, and vessel linings in aggressive environments.

- If your primary focus is reducing friction and wear: Its self-lubricating, low-friction surface is ideal for high-performance bearings, bushings, and non-stick coatings.

- If your primary focus is high-frequency electrical insulation: Its low and stable dielectric constant is essential for critical electronic components and specialized cables.

- If your primary focus is operating in extreme temperatures: Its vast thermal range makes it one of the few materials reliable for both cryogenic and high-heat industrial applications.

Ultimately, PTFE's value is defined by its capacity to function flawlessly in environments where other materials simply cannot survive.

Summary Table:

| Key Property | Key Benefit | Primary Applications |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals | Seals, gaskets, chemical processing linings |

| Low Coefficient of Friction | Self-lubricating, non-stick surface | Bearings, bushings, non-stick coatings |

| Exceptional Thermal Stability | Performs from -200°C to 260°C | Cryogenics, high-heat processes, aerospace |

| Superior Electrical Insulation | Stable dielectric constant, even under heat/moisture | High-frequency electronics, high-performance wiring |

Leverage PTFE's Unique Properties for Your Application

PTFE's unparalleled combination of chemical resistance, low friction, and thermal stability makes it a critical material for solving complex challenges in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in manufacturing high-precision PTFE components—including custom seals, liners, and labware—to meet your exact specifications. Whether you need prototypes or high-volume production, our expertise ensures you get components that deliver reliable performance in the most demanding environments.

Ready to enhance your product's performance with precision PTFE components? Contact KINTEK today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss