In short, Polytetrafluoroethylene (PTFE) is a critical problem-solving material used across nearly every major industrial sector. Its applications range from creating non-stick surfaces in food processing to providing critical seals and insulation in aerospace, chemical processing, and electronics. The material's value is found in both industrial-strength coatings and as precisely machined components like gaskets, bearings, and valves.

The widespread industrial adoption of PTFE is not due to a single feature, but its unique combination of properties. It solves challenges where other materials fail by simultaneously offering extreme chemical resistance, a vast temperature tolerance, and one of the lowest coefficients of friction of any solid.

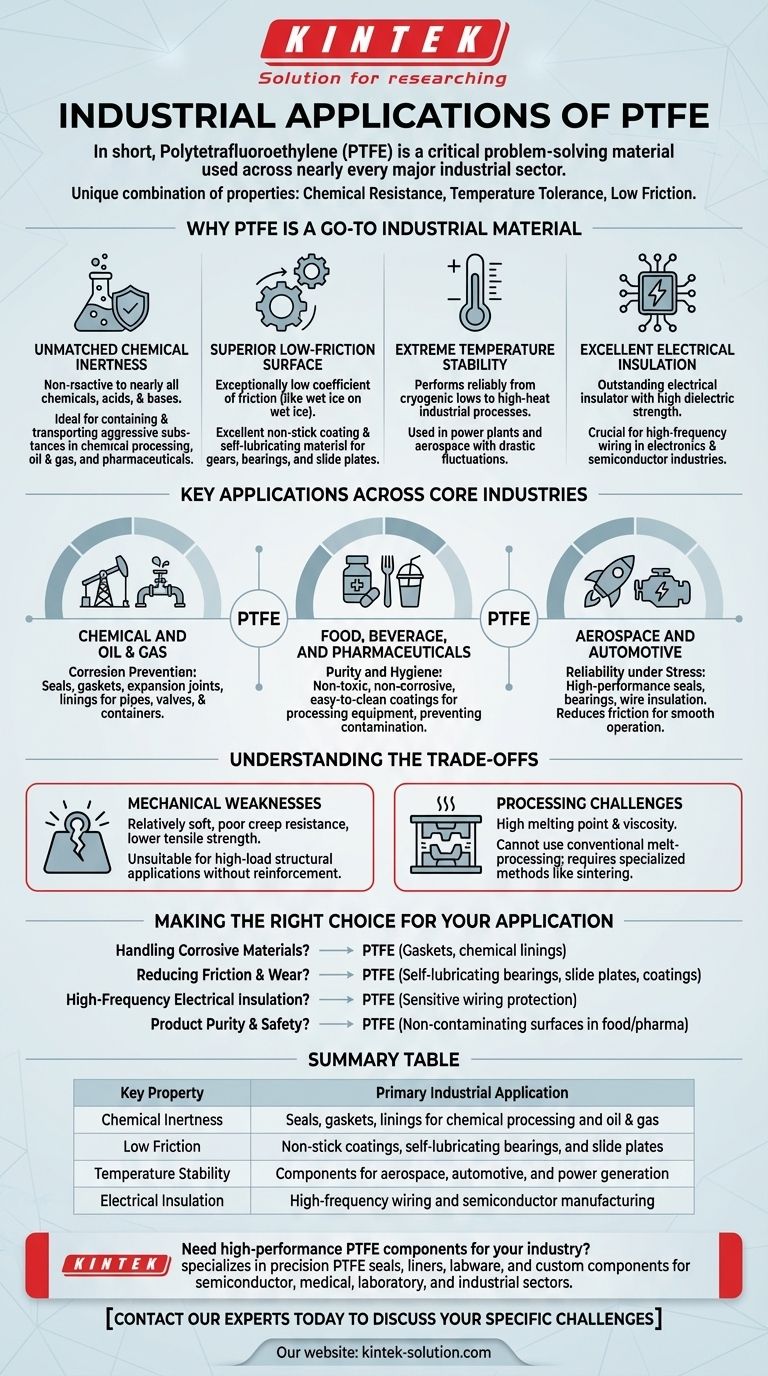

Why PTFE is a Go-To Industrial Material

To understand PTFE's applications, you must first understand the core properties that make it so versatile. It is fundamentally a material engineered for extreme environments.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly all chemicals, acids, and bases. This makes it an ideal material for containing and transporting aggressive or corrosive substances.

This property is why it is specified for equipment in chemical processing plants, oil and gas operations, and pharmaceutical manufacturing.

Superior Low-Friction Surface

PTFE has an exceptionally low coefficient of friction, often compared to wet ice on wet ice. This property, known commercially as Teflon, makes it an excellent non-stick coating and a self-lubricating material.

This reduces energy consumption and wear in mechanical systems, making it perfect for gears, bearings, and slide plates.

Extreme Temperature Stability

PTFE performs reliably across a wide range of temperatures, from cryogenic lows to high-heat industrial processes.

This stability allows it to be used in demanding environments like power plants, which handle high-pressure steam, and in aerospace applications that experience drastic temperature fluctuations.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength, meaning it can withstand strong electric fields without breaking down.

This makes it a crucial material in the electronics and semiconductor industries for insulating high-frequency wiring, such as in coaxial cables and computer hookup wires.

Key Applications Across Core Industries

The properties of PTFE translate directly into tangible components and solutions that are essential for modern industry.

In Chemical and Oil & Gas

The primary application here is corrosion prevention. PTFE is used to manufacture seals, gaskets, and expansion joints that will not degrade when exposed to aggressive chemicals.

It is also used to line pipes, valves, and chemical containers to protect the structural integrity of the equipment and prevent contamination.

In Food, Beverage, and Pharmaceuticals

In these highly regulated industries, purity is paramount. PTFE is non-toxic, non-corrosive, and easy to clean, preventing contamination.

Its non-stick properties are used for coatings on processing equipment to prevent buildup of food or pharmaceutical products, ensuring consistent flow and hygienic conditions.

In Aerospace and Automotive

Reliability under stress is the main driver in these sectors. PTFE is used for high-performance seals, bearings, and wire insulation.

Its ability to reduce friction is critical for components that must operate smoothly with minimal wear over a long lifespan, while its insulative properties protect vital electronic systems.

Understanding the Trade-offs

While incredibly useful, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Mechanical Weaknesses

Compared to metals or other engineering plastics, PTFE is relatively soft and has poor creep resistance, meaning it can deform over time under a constant load.

Its tensile strength and wear resistance are lower than many alternatives, making it unsuitable for high-load structural applications without reinforcement.

Processing Challenges

PTFE has an extremely high melting point and viscosity, which means it cannot be processed using conventional melt-processing techniques like injection molding.

It typically requires specialized and often more costly methods like compression molding and sintering, which can impact manufacturing complexity and cost.

Making the Right Choice for Your Application

Selecting PTFE is about matching its unique strengths to a specific industrial challenge that other materials cannot solve as effectively.

- If your primary focus is handling corrosive materials: PTFE is the definitive choice for gaskets, chemical transport linings, and seals in aggressive environments.

- If your primary focus is reducing friction and wear: It is a superior material for self-lubricating bearings, slide plates, and non-stick industrial coatings.

- If your primary focus is high-frequency electrical insulation: Its dielectric properties make it ideal for protecting sensitive wiring in electronics and aerospace.

- If your primary focus is product purity and safety: PTFE is an industry standard for non-contaminating surfaces in food, beverage, and pharmaceutical processing.

Ultimately, PTFE is the material of choice for applications where performance and reliability in extreme conditions are non-negotiable.

Summary Table:

| Key Property | Primary Industrial Application |

|---|---|

| Chemical Inertness | Seals, gaskets, and linings for chemical processing and oil & gas |

| Low Friction | Non-stick coatings, self-lubricating bearings, and slide plates |

| Temperature Stability | Components for aerospace, automotive, and power generation |

| Electrical Insulation | High-frequency wiring and semiconductor manufacturing |

Need high-performance PTFE components for your industry?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We deliver the reliability your critical applications demand, from custom prototypes to high-volume production.

Contact our experts today to discuss how our PTFE solutions can solve your specific challenges.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss