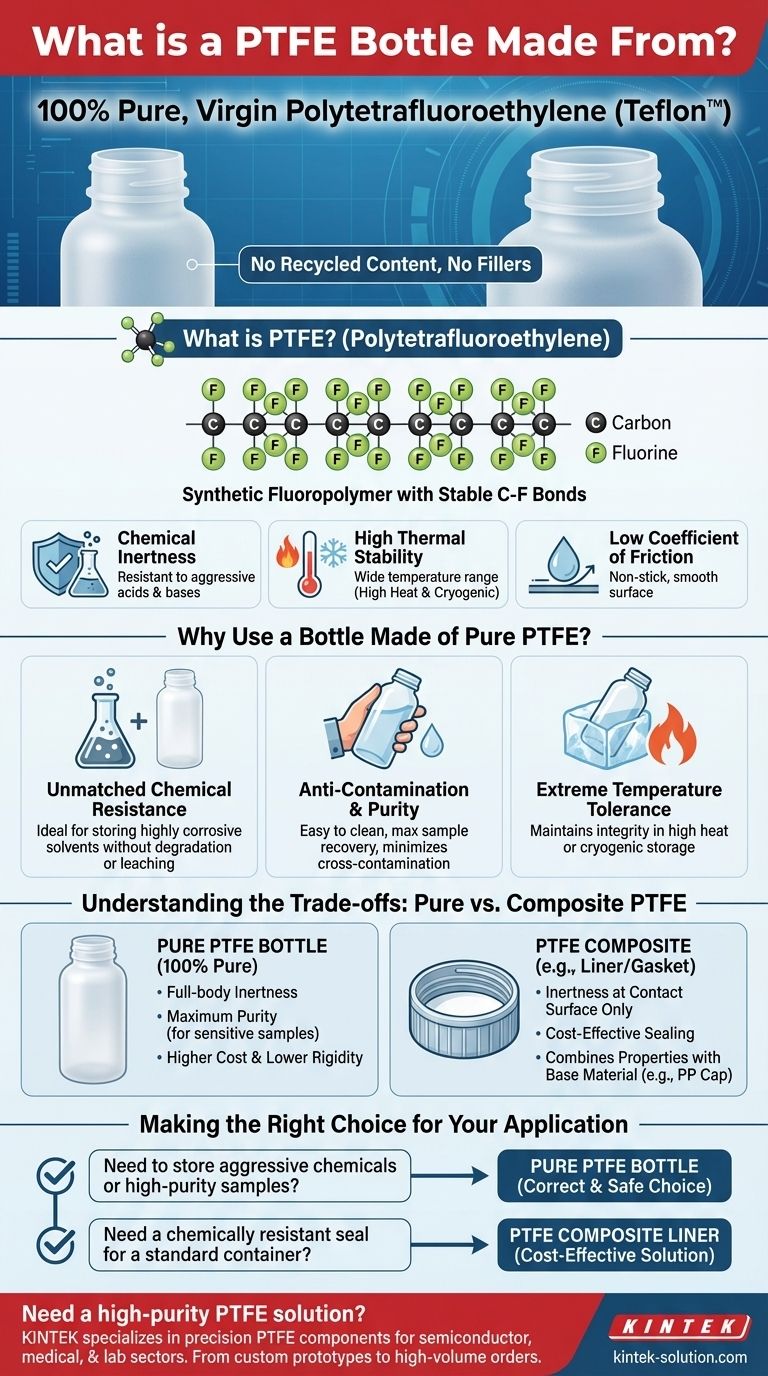

In short, a genuine PTFE bottle is made from 100% pure, virgin Polytetrafluoroethylene. This synthetic fluoropolymer, widely known by the brand name Teflon, is not mixed with other plastics or recycled materials, ensuring maximum performance for demanding applications.

The critical distinction to grasp is that while a PTFE bottle is made of pure Polytetrafluoroethylene, many products like caps or gaskets use PTFE as a specialized liner or coating on a different base material to achieve specific properties at a lower cost.

What is Polytetrafluoroethylene (PTFE)?

PTFE is a high-performance engineered plastic renowned for its unique and valuable combination of properties. Understanding these characteristics clarifies why it is the material of choice for specialty containers.

A Synthetic Fluoropolymer

PTFE is a man-made polymer. Its molecular structure, consisting of a carbon chain fully surrounded by fluorine atoms, is responsible for its remarkable stability and non-reactive nature.

The "Virgin" Material Distinction

When a bottle is specified as being made from virgin PTFE, it means the material is pure and free from any recycled content or fillers. This is crucial for scientific and industrial applications where material purity is non-negotiable to prevent contamination.

Core Chemical Properties

PTFE is defined by three primary characteristics:

- Chemical Inertness: It is extremely resistant to a vast range of aggressive chemicals, including strong acids and bases.

- High Thermal Stability: It maintains its integrity over a wide temperature range and has a very high melting point.

- Low Coefficient of Friction: It has an exceptionally smooth, "non-stick" surface that prevents materials from adhering to it.

Why Use a Bottle Made of Pure PTFE?

Choosing a solid PTFE bottle over less expensive alternatives like glass or other plastics is a decision driven by specific, critical requirements. Its properties make it indispensable for tasks where other materials would fail.

Unmatched Chemical Resistance

For storing or handling highly corrosive solvents, acids, or reactive chemicals, PTFE is often the only viable option. It will not degrade, leach chemicals into the sample, or react with the contents.

Anti-Contamination and Purity

The non-stick surface ensures that every bit of a valuable sample can be retrieved. This low surface energy also makes the bottles easy to clean and minimizes the risk of cross-contamination between uses.

Extreme Temperature Tolerance

PTFE bottles can be used for applications involving high heat or cryogenic storage where other plastic containers would melt, deform, or become brittle.

Understanding the Trade-offs: Pure vs. Composite PTFE

The term "PTFE" is often used broadly, which can cause confusion. It's essential to distinguish between a product made from solid PTFE and one that merely incorporates it.

Pure PTFE (The Bottle)

The bottle itself is an example of a product made from 100% pure PTFE. You get all the benefits of the material's properties throughout the entire object. The primary trade-offs are higher cost and lower mechanical rigidity compared to common plastics.

PTFE Composites (Liners, Gaskets, Coatings)

Many products use PTFE strategically. For example, a bottle cap may be made from inexpensive polypropylene but feature a thin PTFE liner on the inside. This provides a chemically inert barrier where it matters most—at the point of contact with the bottle's contents—without the expense of a solid PTFE cap.

Balancing Cost and Performance

This composite approach is an engineering compromise. You get the critical surface properties of PTFE (inertness, non-stick) combined with the structural strength or lower cost of another material (like polypropylene in a cap or fabric in a bearing).

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is storing aggressive chemicals or high-purity samples: A bottle made from 100% virgin PTFE is the correct and safest choice.

- If your primary focus is creating a chemically resistant seal for a standard container: A cap with a PTFE liner provides a cost-effective and reliable solution.

- If your primary focus is flexibility or mechanical strength in a corrosive environment: A specialized composite, such as a PTFE bellow or fabric-reinforced gasket, is likely required.

Ultimately, knowing whether your application demands the absolute purity of solid PTFE or can be served by a PTFE composite is the key to a successful outcome.

Summary Table:

| Property | Pure PTFE Bottle | PTFE Composite (e.g., Liner) |

|---|---|---|

| Material Composition | 100% virgin PTFE | PTFE layer on a different base material (e.g., PP cap) |

| Chemical Resistance | Full-body, unmatched inertness | Limited to the PTFE contact surface |

| Purity & Anti-Contamination | Maximum; ideal for sensitive samples | Good for the sealed interface |

| Primary Use Case | Storing aggressive chemicals, high-purity samples | Cost-effective sealing for standard containers |

| Cost Consideration | Higher | Lower |

Need a high-purity PTFE solution for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—from bottles and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the absolute purity of a 100% virgin PTFE bottle or a cost-effective composite component, our expertise in custom fabrication from prototypes to high-volume orders ensures you get the perfect part for your needs.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- In what ways are PTFE silicone septas versatile for pharmaceutical applications? Ensuring Sample Integrity from Discovery to QC

- What are the benefits of PTFE shovels being antistatic? Prevent Fires & Protect Sensitive Electronics

- What are the benefits of silicone/PTFE liners? Ensure Unmatched Sample Purity and Integrity

- What are the characteristics of narrow mouth PTFE laboratory bottles? Superior Chemical Resistance & Purity

- What are the key properties of PTFE for sanitary gaskets? Ensuring Purity & Safety in Food & Pharma

- What are the permeability differences between PTFE and silicone septa? Choose the Right Seal for Your Sample Integrity

- What are the advantages of using Teflon membranes in filtration systems? Achieve Unmatched Chemical & Thermal Resistance

- What are the advantages of the PTFE bottle's non-stick surface? Ensure Purity and Efficiency in Your Lab